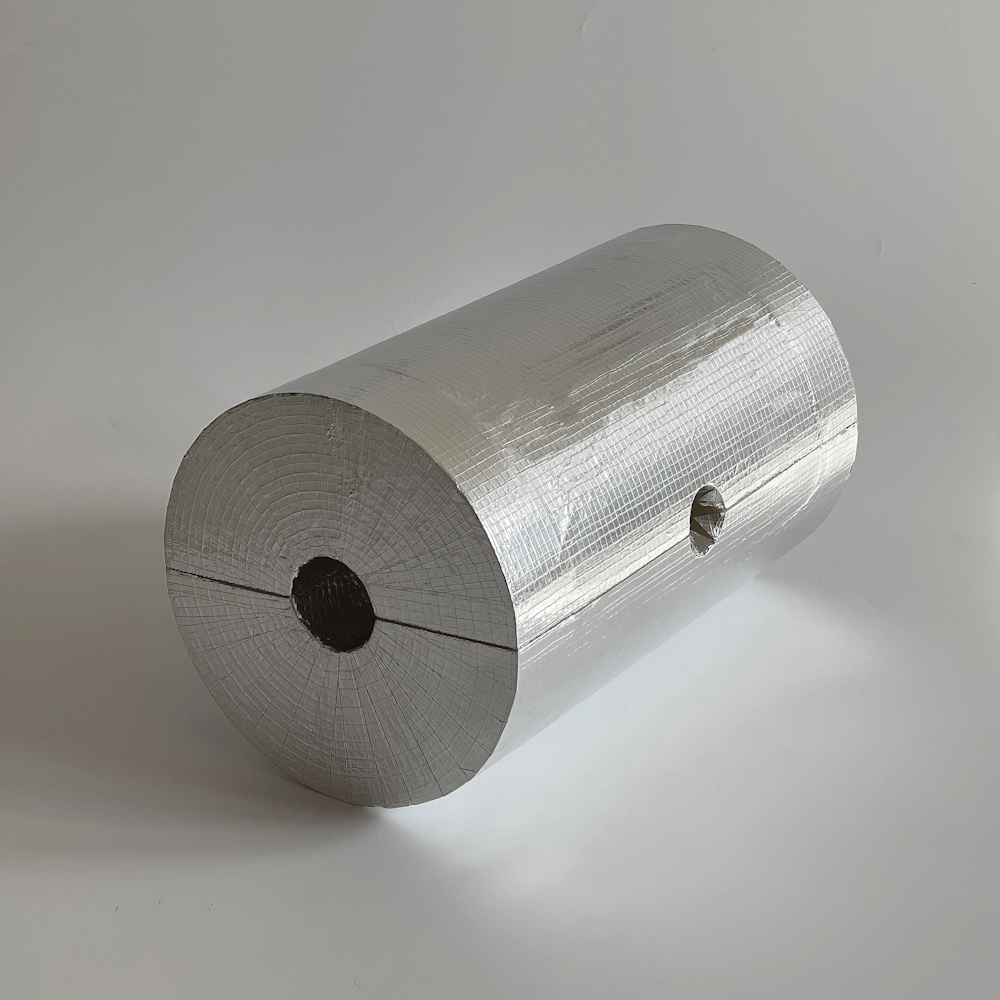

UV protected insulation

Approved according to EN 253

Dan-iso supplies UV-protected pipes and joints for e.g. process plant.

• Molded in foam that is approved according to EN 253.

• Molding equipment with stepless adjustment, which ensures the mixing ratio of the foam to the smallest gram.

• Molded under controlled conditions of constant temperature and humidity, which ensures correct foaming process.

• Optimized amount of closed cells in the foam that ensures the lambda value.

No UV radiation and moisture absorption

Coated pipe insulation is not degraded by UV radiation and does not absorb moisture.

Facts:

• When foaming directly on pipes, you do not know the insulation value and density.

• Foaming on cold media results in a static, sticky dough mass.

• Foaming on hot items causes forced foaming.

• Humidity affects the process just like cold and heat.

• The quality of the joints is just as important as the quality of the pre-insulated pipes.

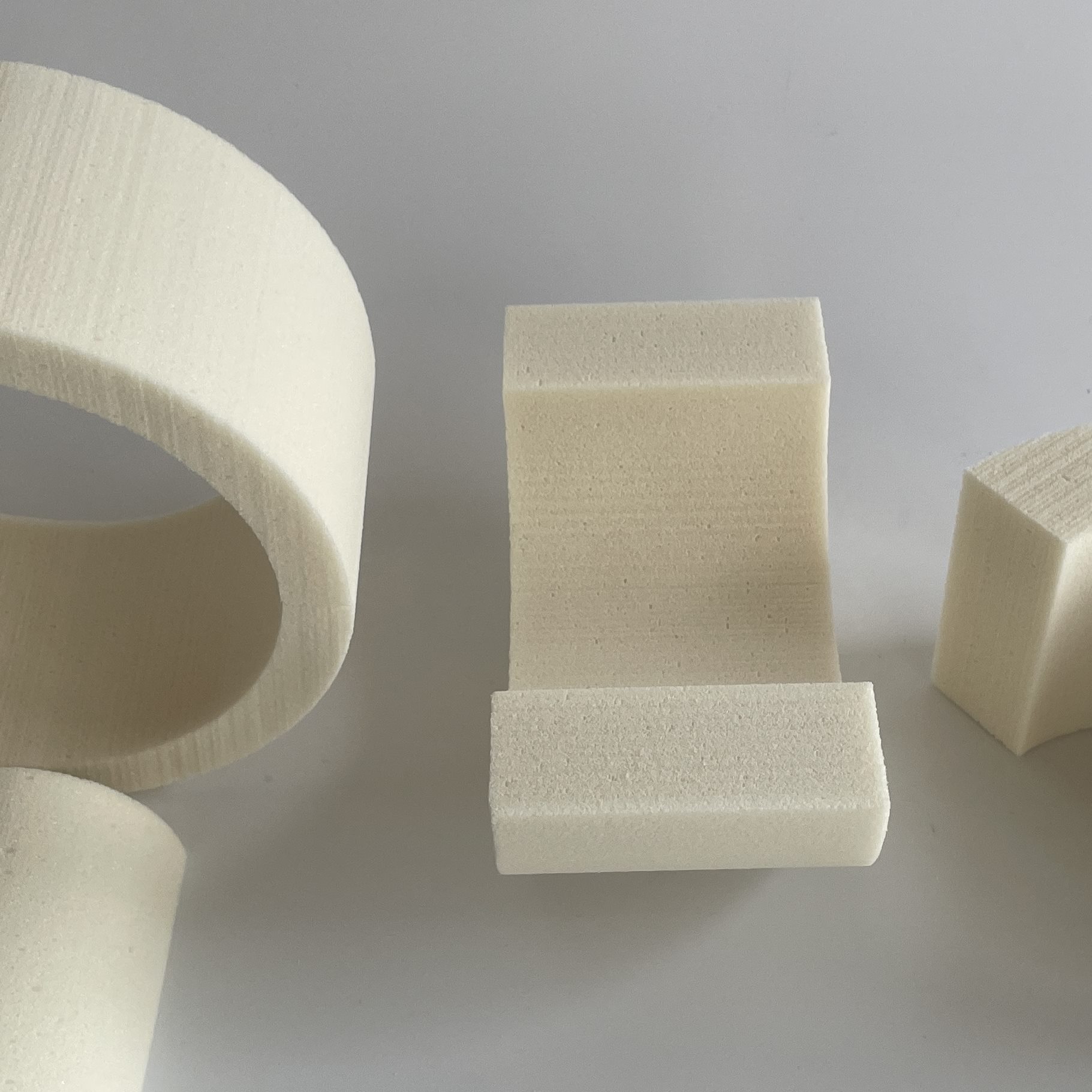

Insulation for outdoor heat pumps and pipes

Pipe insulation with UV-resistant coating is eminent for insulating outdoor pipes. PUR insulation with UV coating is not degraded by the sun, does not absorb moisture and is easy to clean. PUR is suitable for more than coating. It is also suitable for painting or gluing other surfaces.

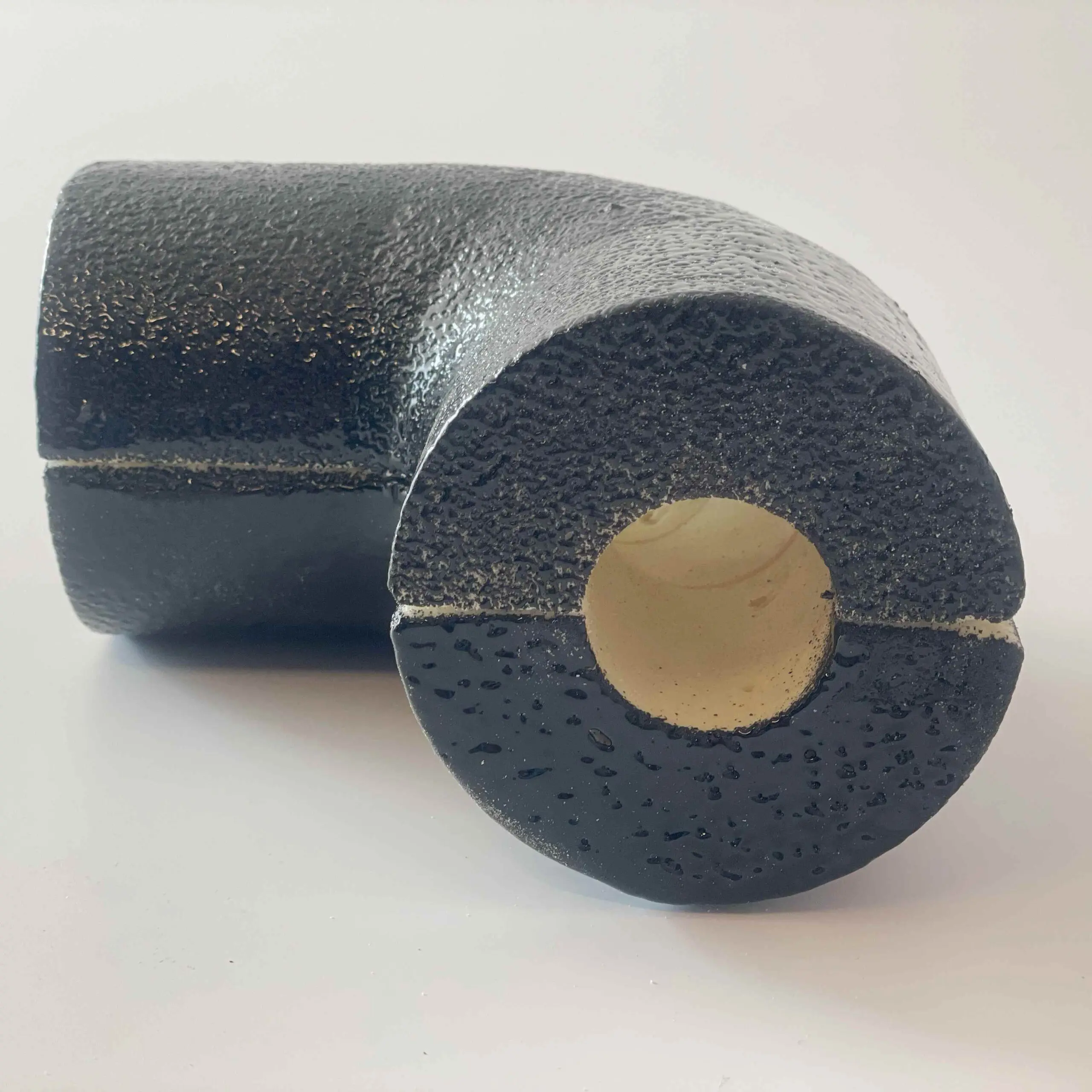

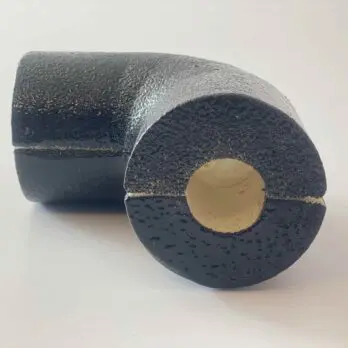

Full length pipe insulation

The quality of the pipe joints is just as important as the quality of the pre-insulated pipes. Achieve the best insulation value with molded insulation cups for pipe joints. Use UV-protected joints for optimal insulation and a durable surface. When you use UV-protected joints from Dan-iso, you do not need to retrofit tin tubes on the insulation.

Application

Coated pipe insulation with UV protection is the ideal solution for outdoor installations where pipes and joints are exposed to the sun's UV rays.

This UV protective insulation prevents degradation and ensures long-lasting protection against the harmful effects of the sun's radiation. It is optimal for applications such as process plants, heat pumps and other systems that require durable insulation in outdoor environments. Our UV-protected pipes and joints are designed to withstand extreme weather conditions, ensuring optimal function and longer life of your installations without the need for frequent maintenance.

Technical data sheet

Download product sheet here and contact us for technical documents or if you need further information.

Technical specifications

| Material properties | Value | Standard |

|---|---|---|

| Density | 68 kg/m3 (±8 kg/m3) | ISO 845 (/DIN 53420-78) |

| Closed cells | ≥ 88 % | ISO 4590 |

| Cell size | < 0.5 mm | EN253 5.3.2.1 |

| Water absorption during boiling | Mean value 4.4 % Vol | EN253 5.3.5 |

| Compressive strength, radial | ≥ 0.40 Mpa | ISO 844 |

| E-module, radial | ≥ 9.5 MPa | ISO 844 |

| Dimensional stability | ||

| -30 C° | 48h: 0.0 % vol | |

| +100 C° | 48h: -1.0 % vol | ISO 2796 (/DIN 53431-77) |

| +150 C° | 48h: -1.4 % vol | |

| Thermal Insulation Value (thermal conductivity) | ||

| λ10 | 0.0238 W/m*K | |

| λ20 | 0.0247 W/m*K | ISO 8301 / ASTM C518 |

| λ50 | 0.0284 W/m*K | |

| Fire class | B3 | DIN 4102 Part 1 |