Optimization at MAMMEN Dairies A/S

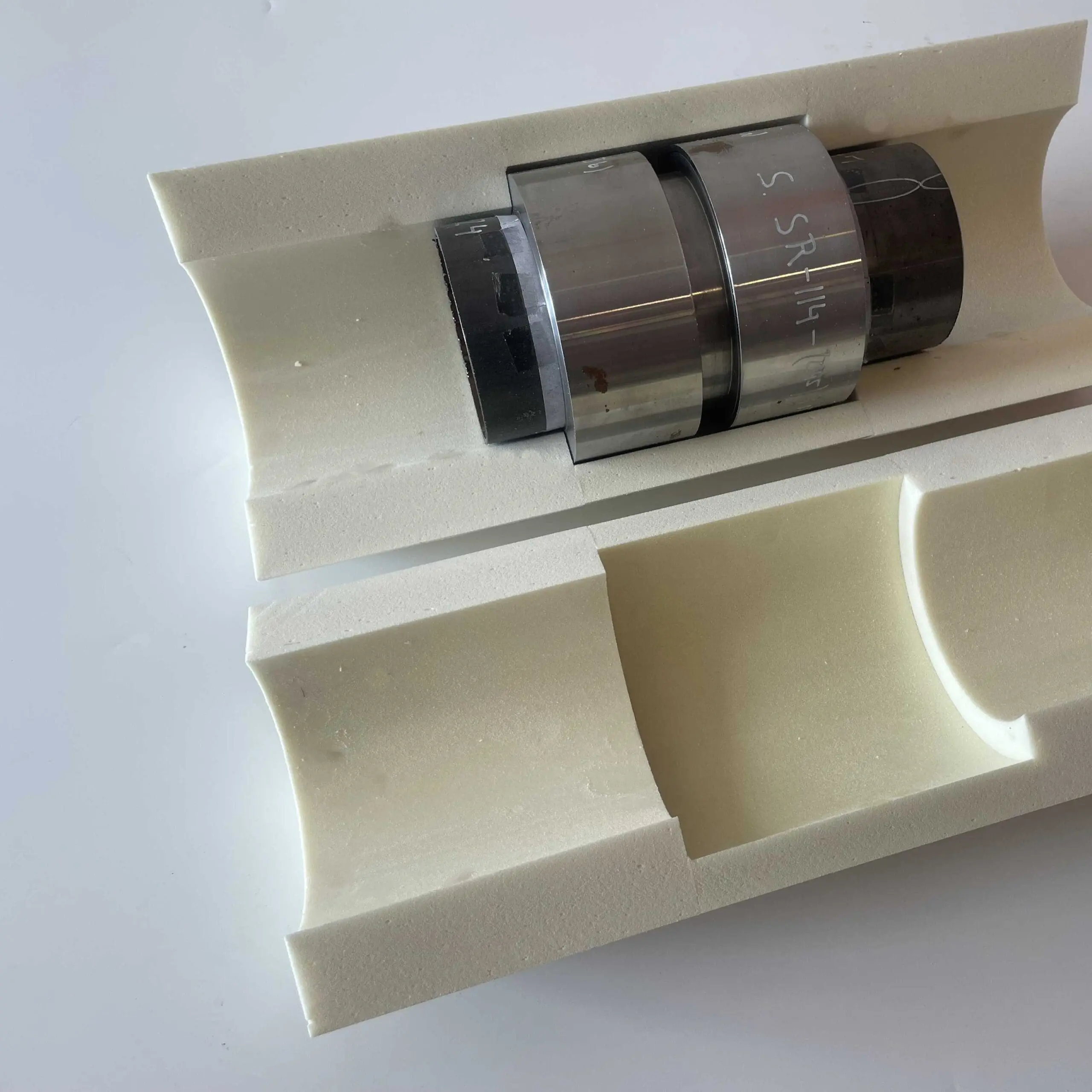

- Food-approved surface according to EU Directive 2011/10/EC.

- Waterproof solution that effectively protects against corrosion

- High insulation value and compressive strength that makes it easy to wipe off or clean with a high-pressure cleaner.

"We wanted to insulate the pipes especially in our production, to avoid temperature fluctuations and to avoid condensation dripping on our products. This was not only a question of quality, but also energy," explains Technical Manager Peter Bech Sandahl.

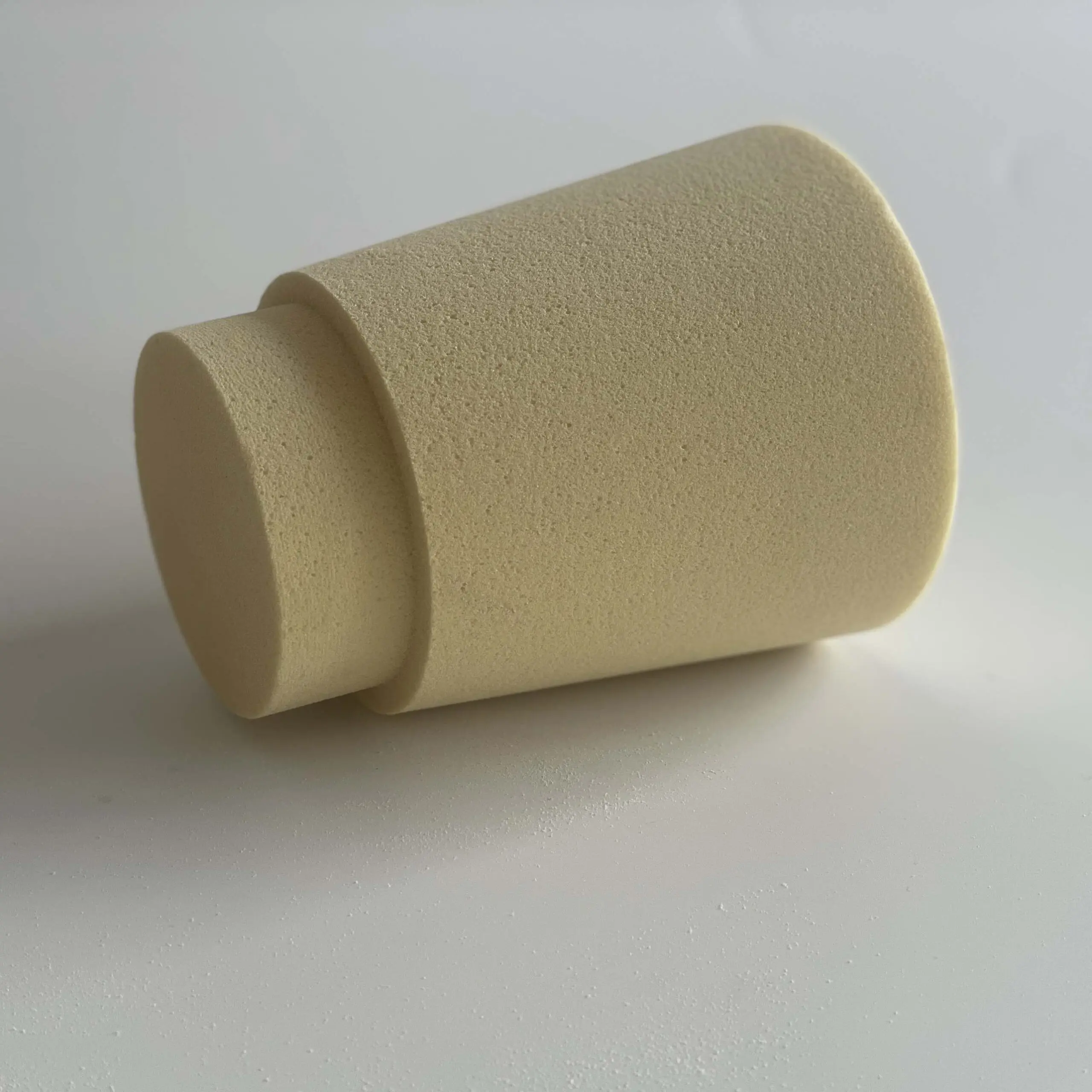

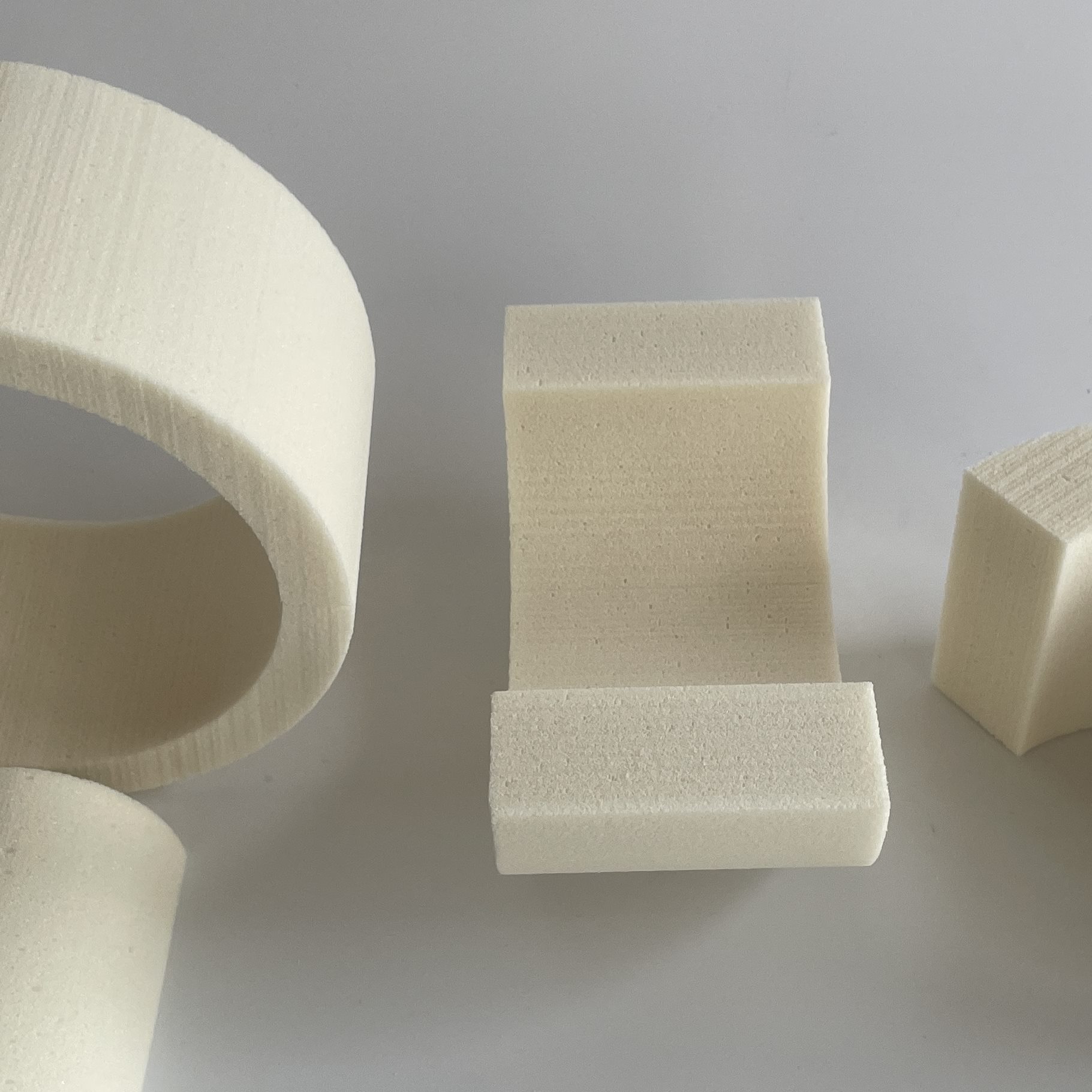

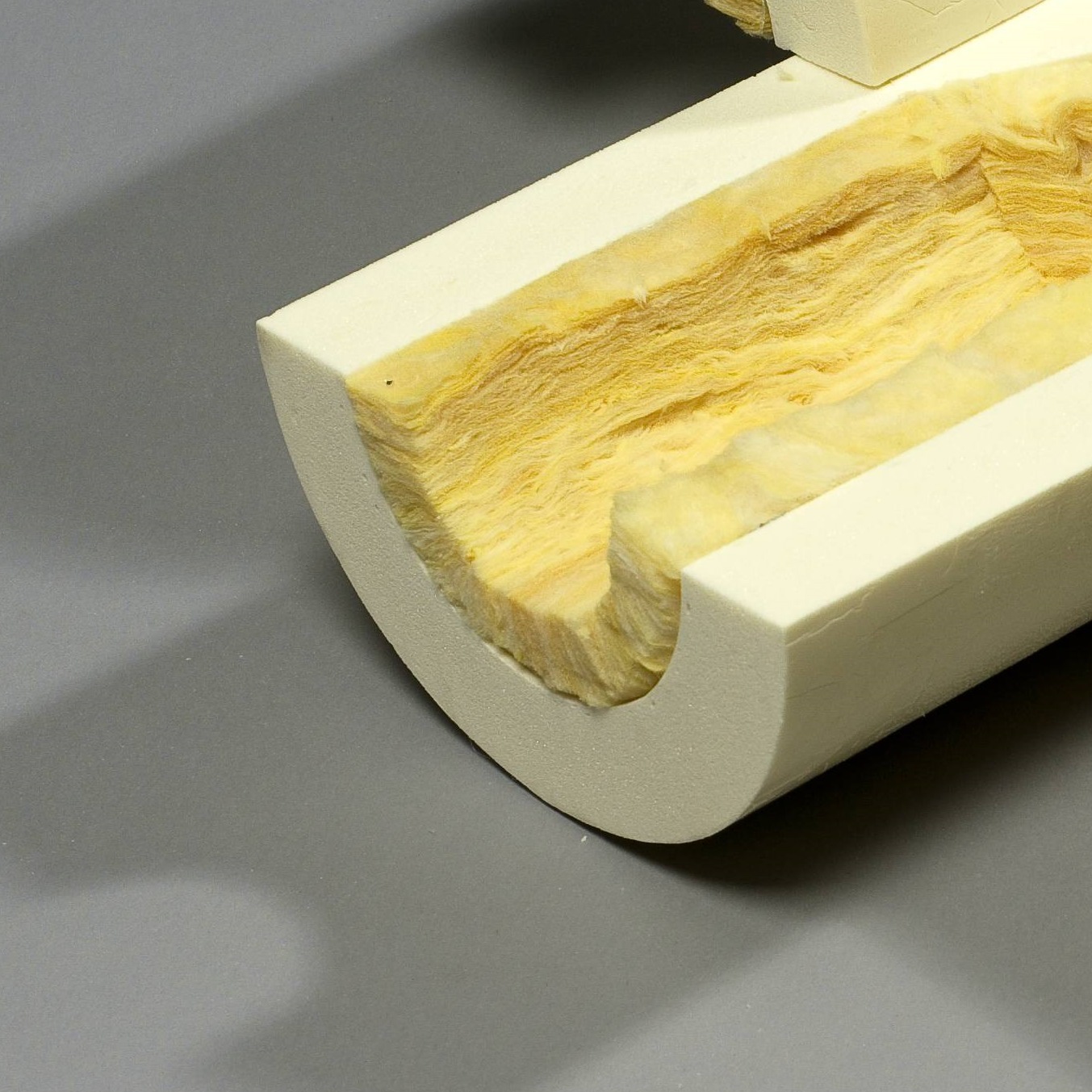

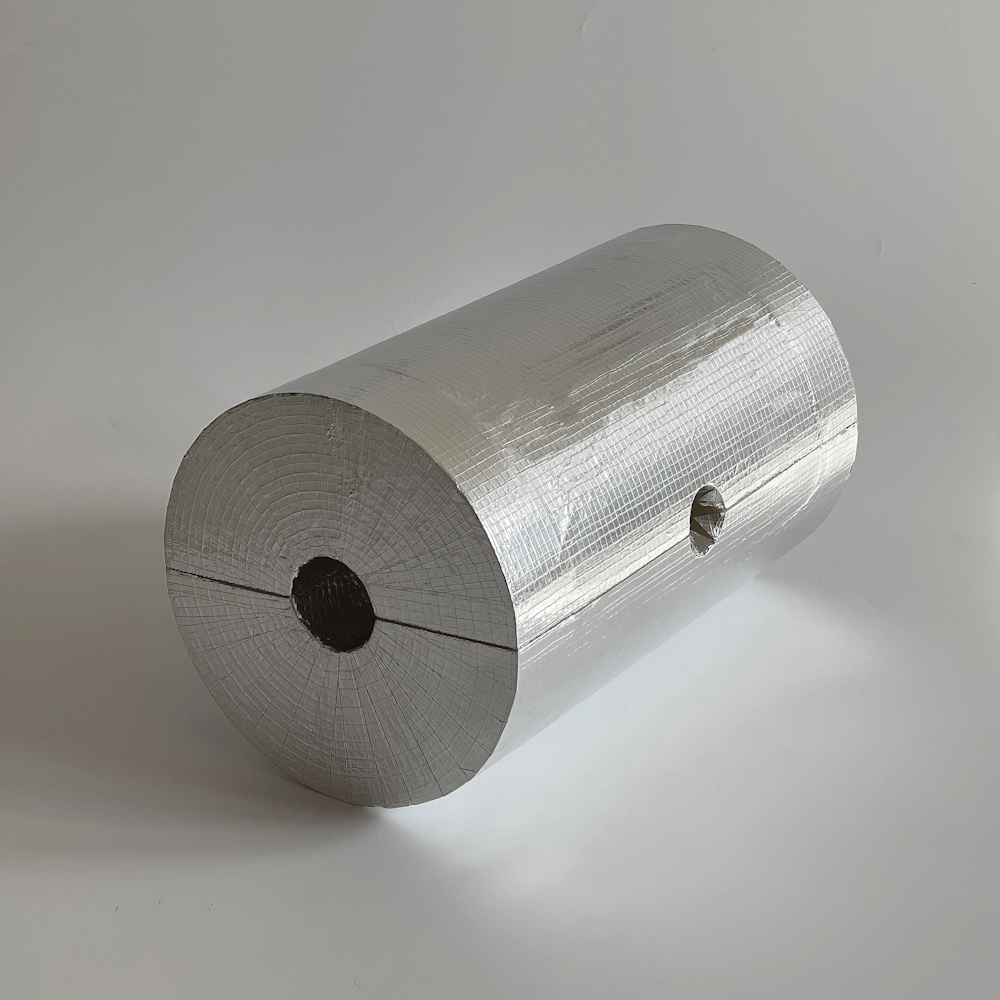

MAMMEN Mejerierne A/S, in collaboration with Dmois A/S, has optimized both the production environment and product quality by installing Dan-isoCLEAN – a molded PUR pipe insulation with a food-approved surface.

"We wanted to insulate the pipes especially in our production, to avoid temperature fluctuations and to avoid condensation dripping on our products. This was not only a question of quality, but also energy," explains Technical Manager Peter Bech Sandahl.

Economic benefits and accountability

Technical Manager Peter Bech Sandahl from MAMMEN Dairies talks about challenges with temperature fluctuations and the risk of condensation that could drip onto the products. Insulating pipes was necessary to ensure quality and energy.

"We have noticed a big difference. There are no longer the same temperature fluctuations, and this has had a positive effect on the working conditions. We now have a more stable and temperate environment, which is what we wanted," says Peter Bech Sandahl, technical manager at MAMMEN Dairies.

"In addition, cleaning has become easier. The food-approved surface has made it possible to keep the pipe insulation free of bacteria, while also resisting the strong chemicals used in cleaning. We clean with strong chemicals, and the pipe insulation has held up without any problems," adds Peter Bech Sandahl.

Improvements in production environment and quality

After installing Dan-isoCLEAN, MAMMEN Dairies A/S has noticed significant improvements in the production environment. The molded PUR pipe insulation has provided a more stable temperature in production, which has resulted in better working conditions and higher product quality.

Future perspectives

MAMMEN Dairies A/S wants to expand the use of Dan-isoCLEAN insulation to more areas in their production. Peter Bech Sandahl emphasizes that the solution has proven to be really effective, and that they therefore want to continue implementing it in future installation projects.

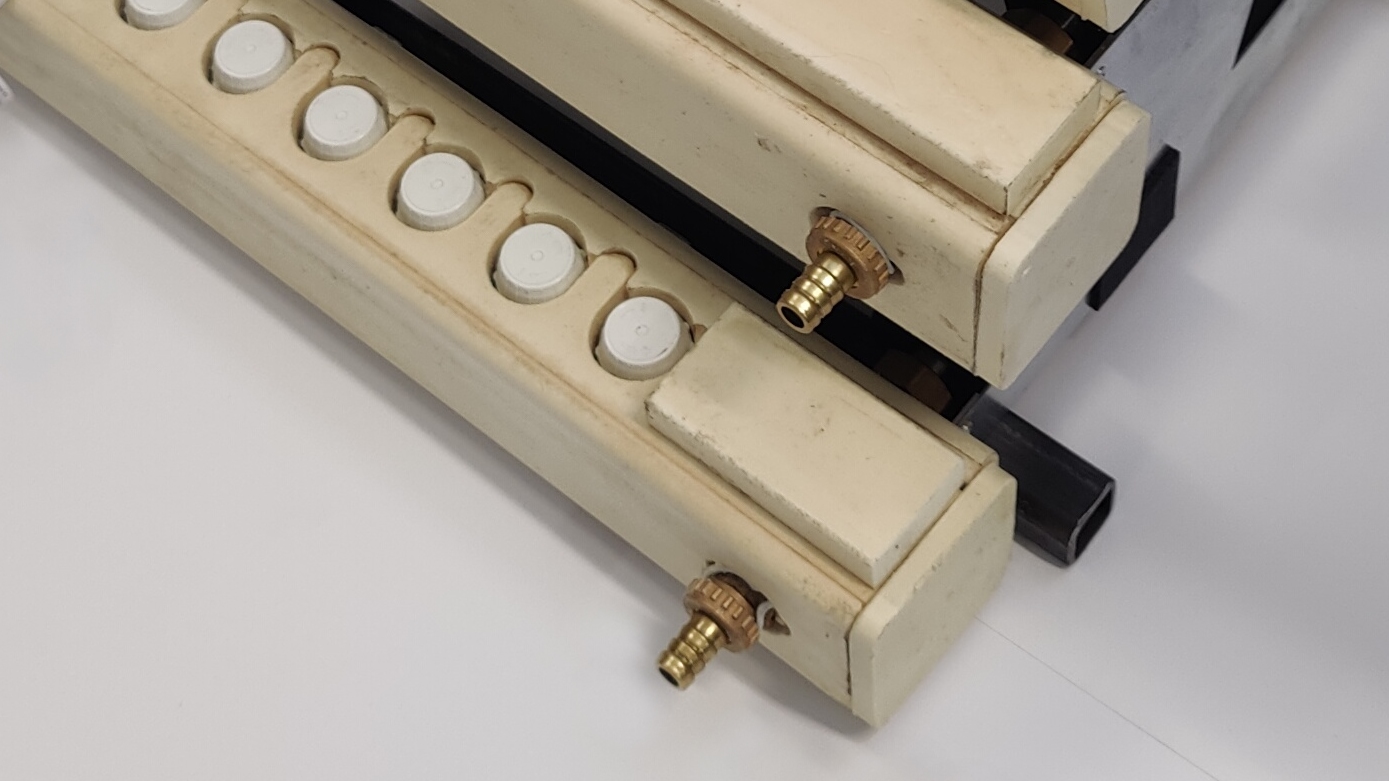

Project: PROCES-DATA A/S

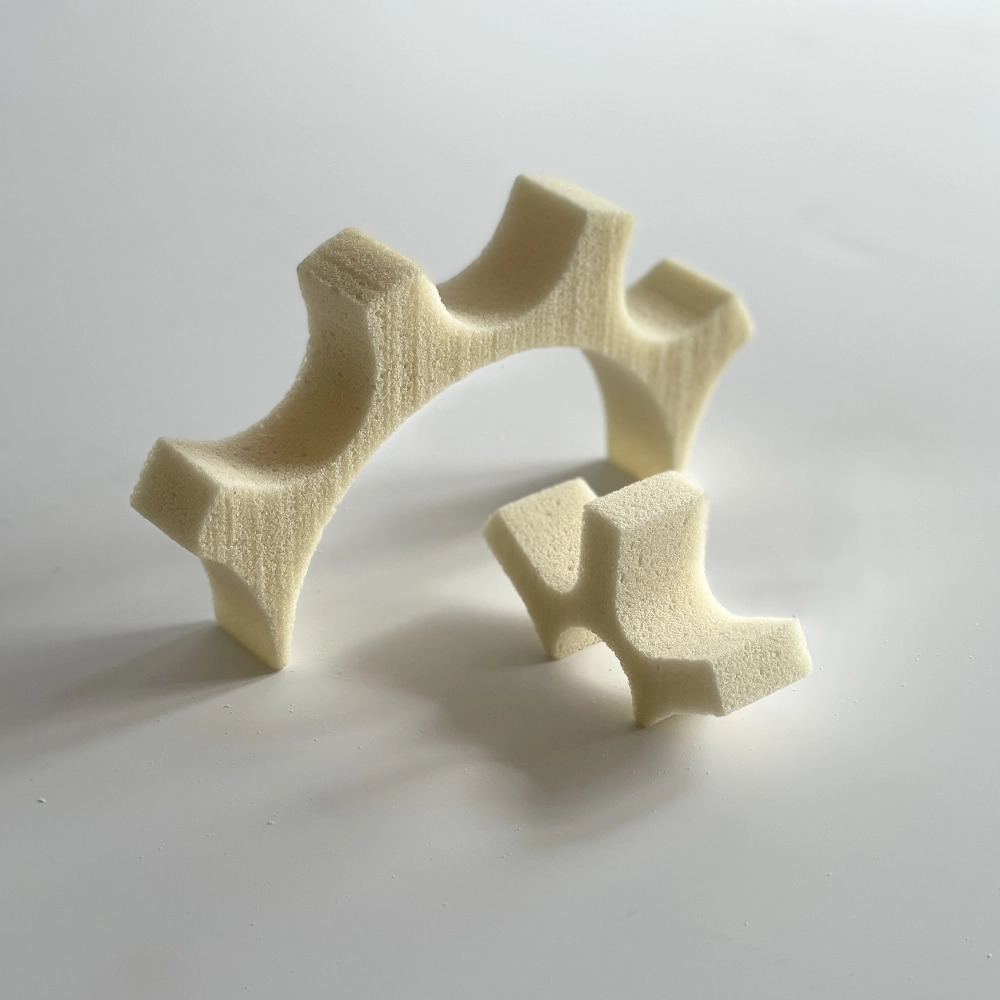

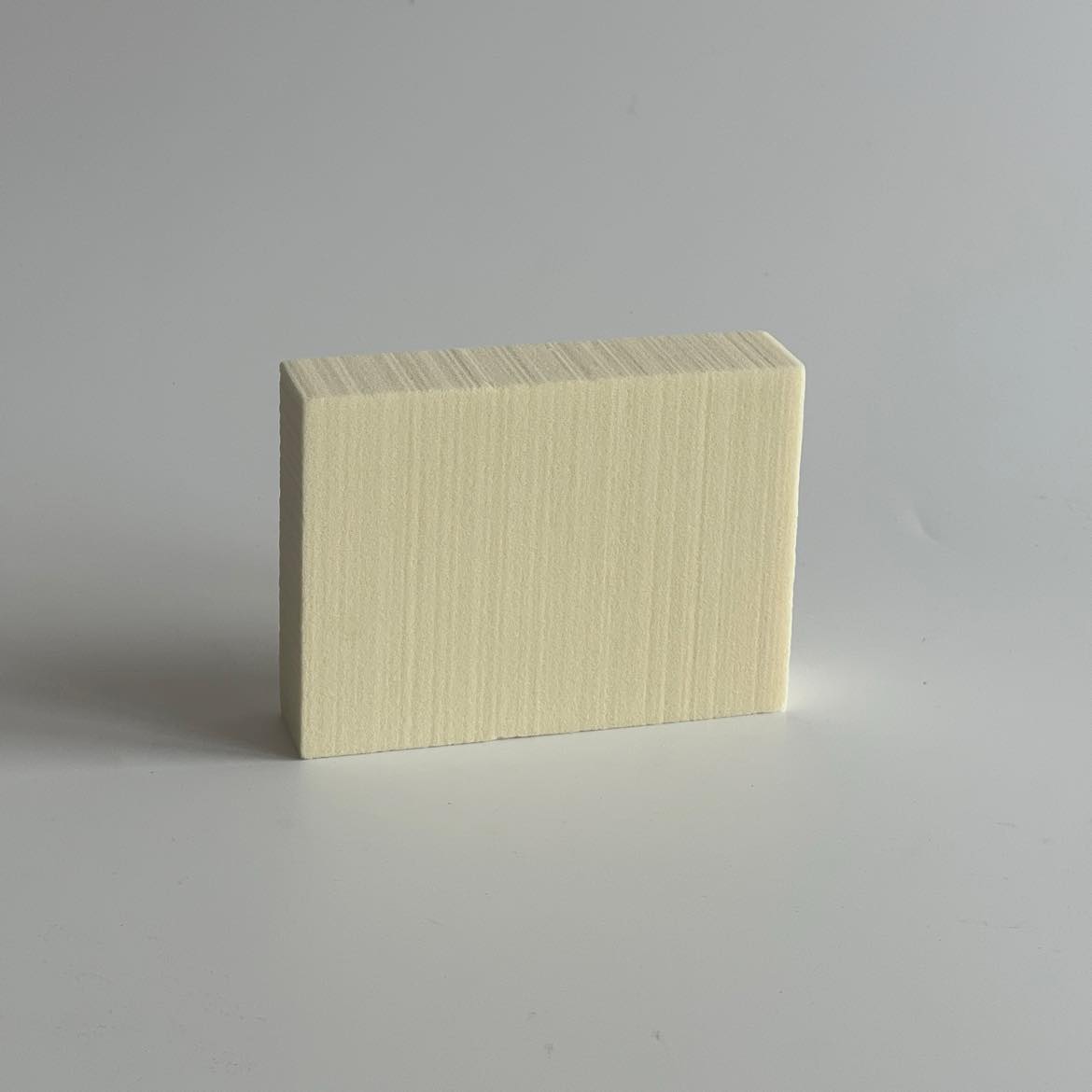

Polyurethane products

Let us assist you

Do you have questions or need help? Please do not hesitate to contact us - we look forward to hearing from you.