Working with polyurethane – focus on safety and correct handling

Safety measures when working with polyurethane

Working with ready-made foam does not require any special safety measures. However, this is not the case when working with polyurethane foam. Foaming polyurethane involves mixing the raw materials isocyanate and polyol to produce polyurethane foam. From 24 August 2023, appropriate training will be required before industrial or commercial use of products containing more than 0.1% by weight of isocyanates.

Training requirements and courses for safe working with isocyanates

Only persons who have undergone special training may work with polyurethane foaming. The education is offered by institutions for vocational education, such as AMU centers and technical schools.

Employers or self-employed persons who use the products themselves or weld must also have undergone the training before starting work. Everyone who works with isocyanate must complete a two-day course.

All employees who work with isocyanates and have an increased risk of exposure to the substance must complete a specific AMU course on personal safety. The course lasts 1 day.

General courses and announcements completed at Dan-iso a/s

- Personal safety when working with epoxy and isocyanates

- Personal safety with isocyanates with increased risk

- Work with epoxy and isocyanate-containing products

- Appendix 3 to the Norwegian Working Environment Authority's order no. 381 of 12 April 2023 on work with substances and materials (chemical agents)

Advantages of handling Rigid Polyurethane Foam (PUR Foam)

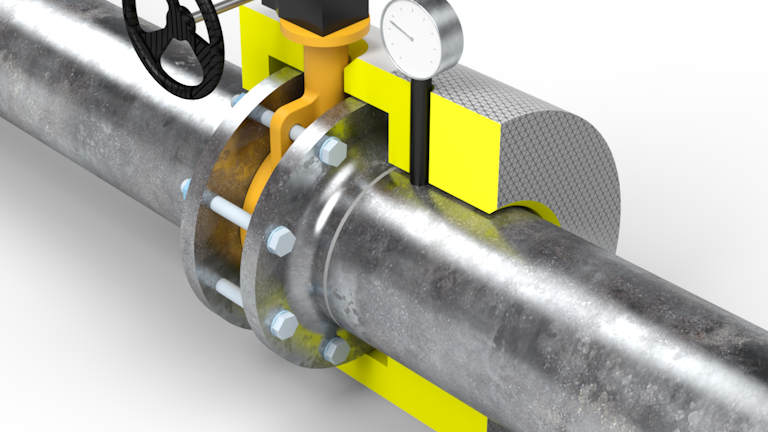

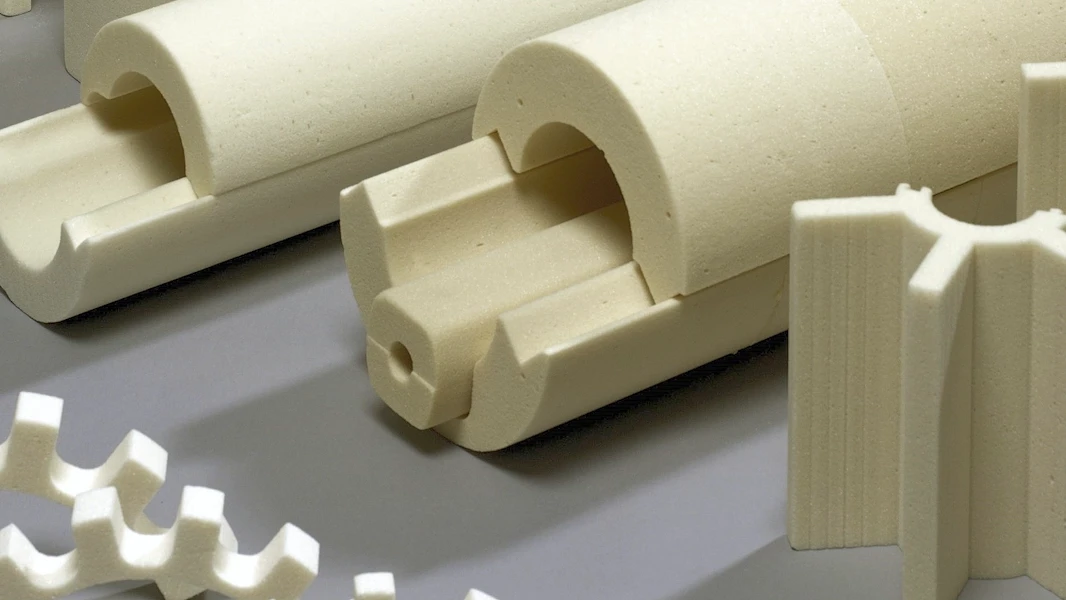

Rigid polyurethane foam (PUR foam) is a thermosetting plastic known for its safe handling and use. The material has several advantages that make it a popular choice in industrial and construction engineering applications. One of the most notable features of rigid PUR foam is its ease of handling. It can be easily cut, shaped and adapted to different applications without the need for advanced equipment or technical skills. This feature makes it ideal for both DIY projects and professional applications.

PUR foam is also known for its low weight in relation to its strength and insulating properties. This makes it easy to transport and install, while providing excellent insulation. It is ideal for insulating walls, ceilings, floors in buildings, as well as pipes and technical installations.

Resilience and Energy Efficiency

An important advantage of rigid PUR foam is its resistance to moisture and mold growth. This feature makes it a reliable choice in wet rooms and other environments where humidity may be a concern. Finally, PUR foam is known for its energy efficiency. It provides excellent thermal insulation, which helps to reduce energy consumption and maintain comfortable temperatures indoors. This makes it a greener choice, as it can help reduce energy consumption and CO2 emissions.

Overall, rigid polyurethane foam is a versatile and reliable material that combines ease of handling, strength, insulation and durability. A favorite in the building and construction industry, it provides effective solutions for a wide range of applications.

Read other related news

Our employees are the foundation

Strong results are created by people who thrive – both professionally and personally. Therefore, employee well-being and proper working conditions are a…

Effective insulation of external heat pumps

When it comes to pipe insulation of outdoor heat pumps, precise temperature conditions and material properties play a crucial role in…

The core of our forging department in Havbro

Our forging department's commitment to quality is not just about producing strong and reliable molds – it also helps reduce material…

Energy optimization in the district heating sector

In a world where energy optimization and sustainable solutions have become our shared responsibility, insulation plays a major role. When we talk about…

Centrifugal Pump Insulation: The Overlooked Key to Efficient Operation

As the industry increasingly focuses on energy efficiency and sustainable solutions, it is no longer enough to just insulate pipes. A…

What is isocyanate – and what role does it play?

Isocyanates are central to the production of PUR and PIR insulation. Get an overview of properties, applications and safety in technical insulation.

Dan-iso invests in solar panels – A step towards a greener future

2024 was concluded with the installation of solar panels at Dan-iso A/S, and we are happy to be able to take this important step towards a greener future.…

What is polyurethane PUR/PIR insulation?

Polyurethane insulation, also known as polyurethane, and colloquially called PUR, is produced by mixing two liquids, polyol and isocyanate. The carefully…