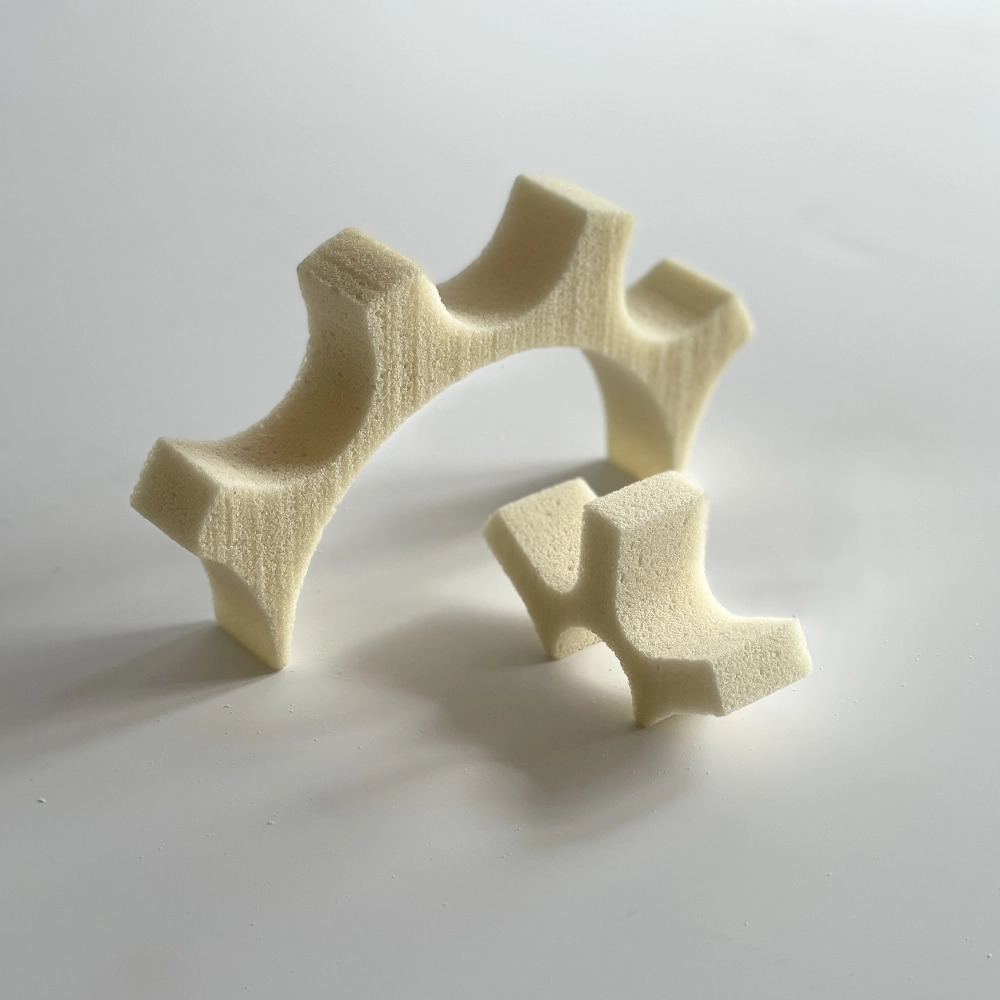

PUR spacers for pre-insulated pipes

Dan-iso's PUR spacers are designed to ensure a centered and uniform foaming of pre-insulated pipes. They are placed between the service pipe and the jacket pipe and ensure the correct distance, which prevents cold bridges and unwanted ice formation. The spacers have the same thermal and mechanical properties as the rest of the PUR insulation and contribute to optimal insulation performance throughout the entire length of the pipe.

PUR spacers are typically used for district heating pipes and cold media such as liquid nitrogen, LNG, LPG and refrigerants. They can also be used between flat surfaces and mounted with adhesives or mechanical solutions – depending on the design and task.

Dan-iso offers both standard dimensions and specially designed spacers in PUR and PIR, adapted to pipe diameter, weight and insulation thickness as well as jacket pipe type. Contact us for advice and development of solutions for your specific project.

Application

Application

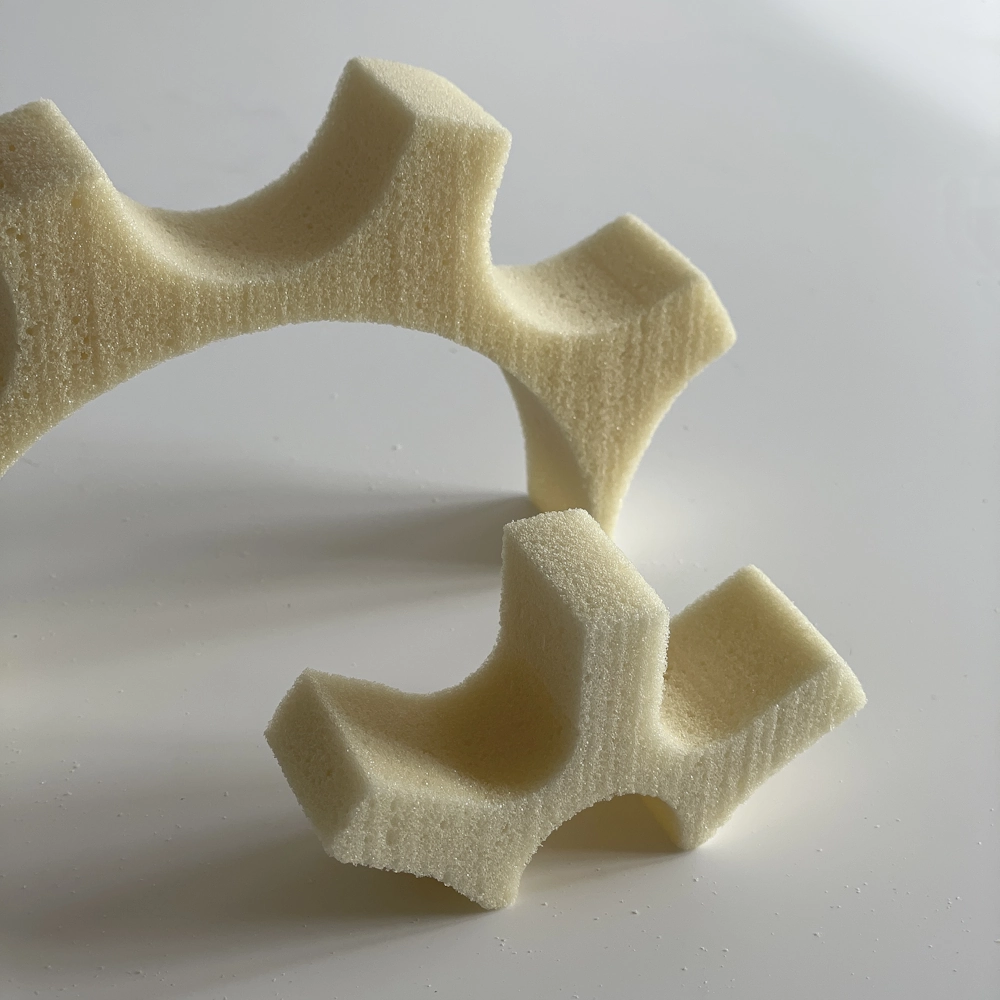

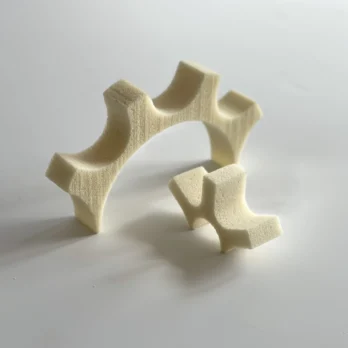

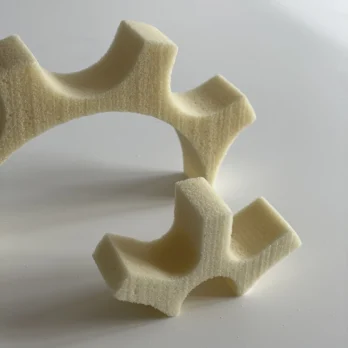

PUR spacers are used for centered and uniform foaming of pre-insulated pipes, where high demands are placed on insulation performance. They are placed between the service pipe and the jacket pipe and ensure the correct distance, which prevents cold bridges and unwanted ice formation. The spacers are adapted to the pipe diameter, weight and insulation thickness and are typically used for district heating pipes as well as cold media such as LNG, LPG, nitrogen and refrigerants. They can also be used between flat surfaces and mounted with adhesives or mechanical solutions. Dan-iso offers specially designed spacers in PUR and PIR adapted to specific tasks and jacket pipe types.

Technical data sheet

Contact us for product sheet.

Technical specifications

| Material properties | Value | Standard |

|---|---|---|

| Density | > 40 kg/m3 | ISO 844 |

| Compressive strength (Lowest perpendicular to the foam direction) | > 0.25 kPa | ISO 845 |

| E-module | > 12 mPa | ISO 844 |

| Stability | - 1 Vol % (100°C) | ISO 2796 |

| Lambda (Lowest perpendicular to the foam direction) | < 0.0284 W/m*k (10°C) | ASTM C518 |

| Closed cells | 88 % | ISO 4590 |

| Water absorption | 4.4 Vol % | EN 253 |