Floor insulation – effective, durable and future-proof solution

- Lower energy consumption and operating costs

- More uniform floor temperatures and better comfort

- Reduced risk of thermal bridges and condensation

- A healthier and more stable indoor climate

Floor insulation plays a crucial role in both energy efficiency, indoor climate and the overall lifespan of the building.

For commercial construction, industry, technical rooms and renovation projects, today there are high demands for low heat loss, minimal space requirement, documentable performance and long durability.

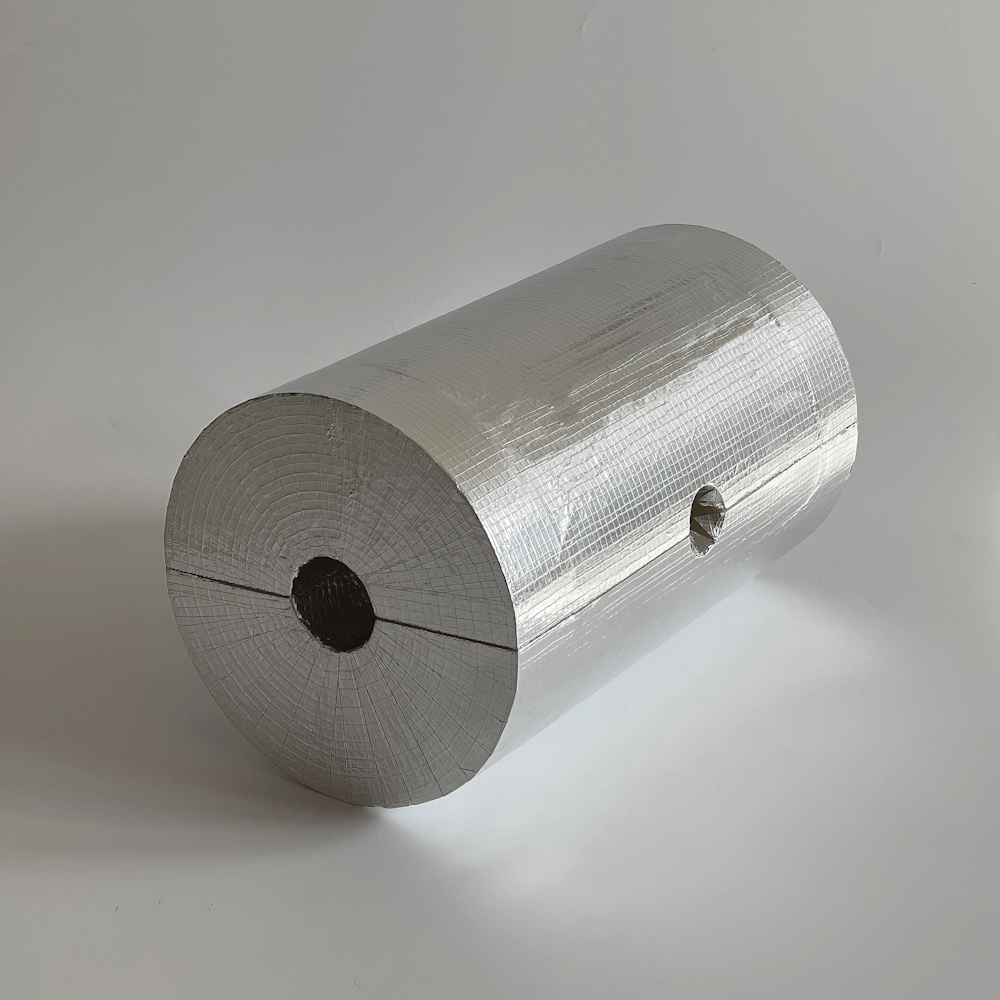

At Dan-iso, we produce highly durable insulation solutions made of PUR (polyurethane) and PIR (polyisocyanurate) – materials that in many applications provide significant advantages compared to traditional insulation materials such as mineral wool, EPS and XPS.

We also offer our environmentally friendly variant, Dan-isoRECY, which is made from recycled polyurethane, providing the same technical properties as standard PUR/PIR, but with a reduced CO₂ footprint.

Why is floor insulation so important?

An inadequately insulated floor structure can account for a significant portion of the building's total heat loss. This applies to both new construction and renovation, where older structures often have poorer insulation. Correct and effective floor insulation can therefore have a major impact on the building's energy optimization and indoor climate. Good floor insulation contributes to:

- Lower energy consumption and operating costs

- More uniform floor temperatures

- Reduced risk of thermal bridges and condensation

- A healthier and more stable indoor climate

PUR and PIR – high insulation performance in minimal space

PUR and PIR insulation are known for their very low thermal conductivity (λ value) compared to mineral wool and other conventional materials.

Comparison (typical values):

- PUR/PIR: approx. 0.022–0.026 W/mK

- Mineral wool: approx. 0.034–0.037 W/mK

This means that the same insulation performance can be achieved with significantly less thickness. For commercial buildings and technical installations, this is often crucial – especially where:

- The building height is limited.

- There are requirements for low construction height

- Existing floors are renovated

Advantages of PUR/PIR over mineral wool and other materials

1. High compressive strength – ideal for floor constructions

PUR and PIR have a high compressive strength, which makes them particularly suitable for floors with loads from:

- Machinery and technical equipment

- Warehouse and industrial floors

- Technical rooms and installation areas

Mineral wool, on the other hand, is more compressible and often requires extra structural layers to achieve the same stability.

2. Low moisture absorption

PUR/PIR are closed-cell materials that absorb very little moisture. This reduces the risk of:

- Reduced insulation capacity over time

- Mold and moisture-related damage

Mineral wool can lose its insulating properties if exposed to moisture – a fact that is often highlighted in construction advice.

3. Long service life and stable performance

PUR and PIR insulation retain their insulating properties for many years and are known for their dimensional stability, meaning fewer problems with settlement and subsequent heat loss.

4. Energy efficiency and CO₂ reduction

The high insulation capacity means lower energy consumption throughout the building's lifetime. With dan-iso purRECY you also get an environmentally friendly alternative with recycled PUR, without compromising on technical performance.

Key technical data – PUR and PIR floor insulation

λ value (thermal conductivity)

PUR and PIR insulation typically has a λ value of 0.022–0.026 W/mK, which means that high insulation performance is achieved with less material thickness compared to mineral wool and EPS.

Compressive strength

PUR/PIR has high compressive strength and dimensional stability, making the material suitable for floor structures with point and surface loads from machinery, furniture and technical installations.

Moisture and durability

The material's closed cell structure provides very low moisture absorption. The insulation capacity remains stable – even over time, which also applies to purRECY.

Workability

The material can be precisely adapted and allows for uniform solutions in both new construction and renovation.

Let us assist you

Do you have questions or need help? Please do not hesitate to contact us - we look forward to hearing from you.