From specially developed lightweight components to sustainable recycling solutions, PUR can be an important part of the wind power projects of the future.

- Very high insulating capacity

- High strength/weight ratio

- Torsional stability

- Temperature stability

- Chemical resistance

The use of PUR in the wind industry opens up new opportunities for innovation and efficiency.

The wind industry is at the forefront of the development of sustainable energy solutions, and with polyurethane (PUR) you have a versatile material available to support this mission. PUR not only enables the manufacture of lightweight components, but also opens up opportunities for recycling, which is crucial in working for a greener future.

Innovative use of PUR in the wind industry

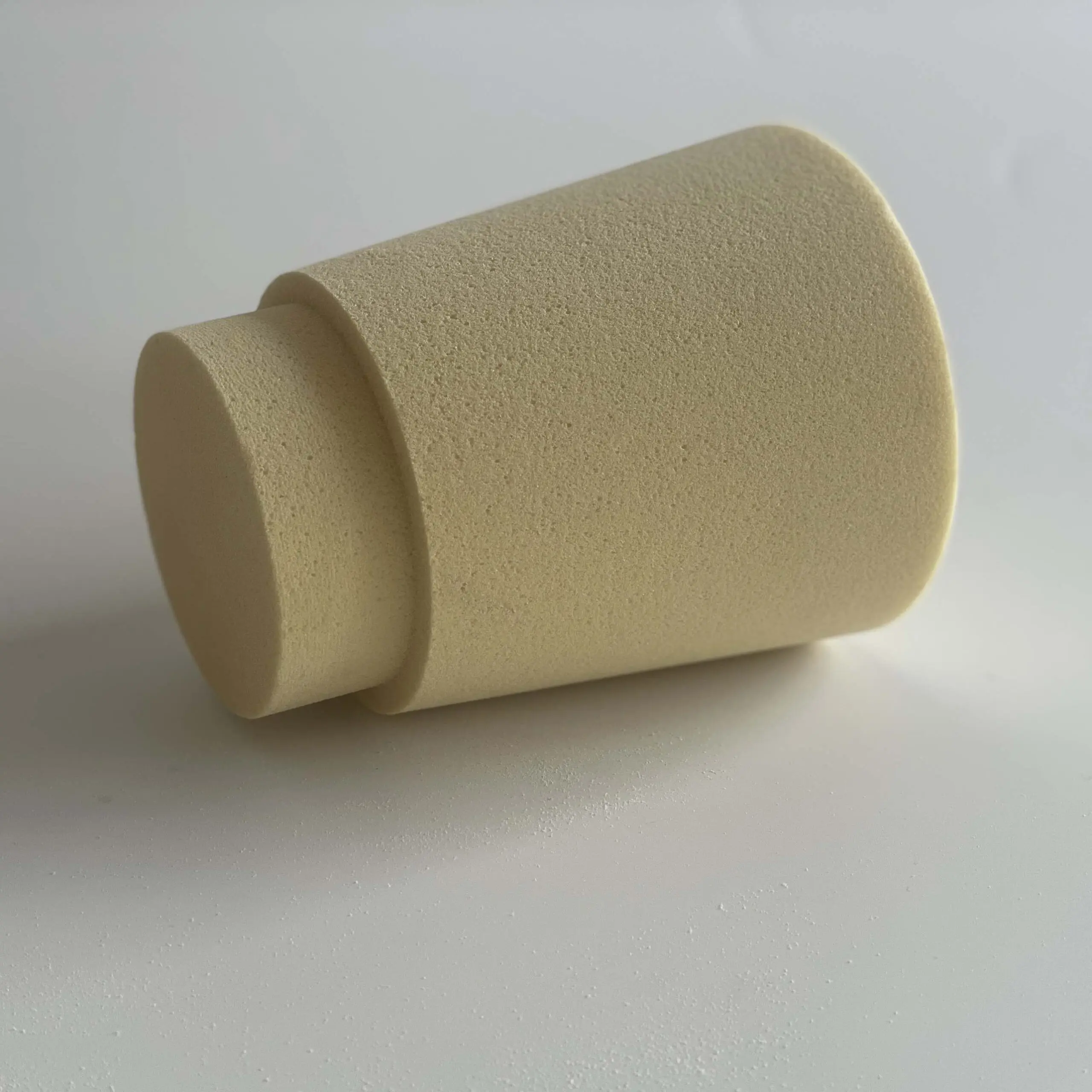

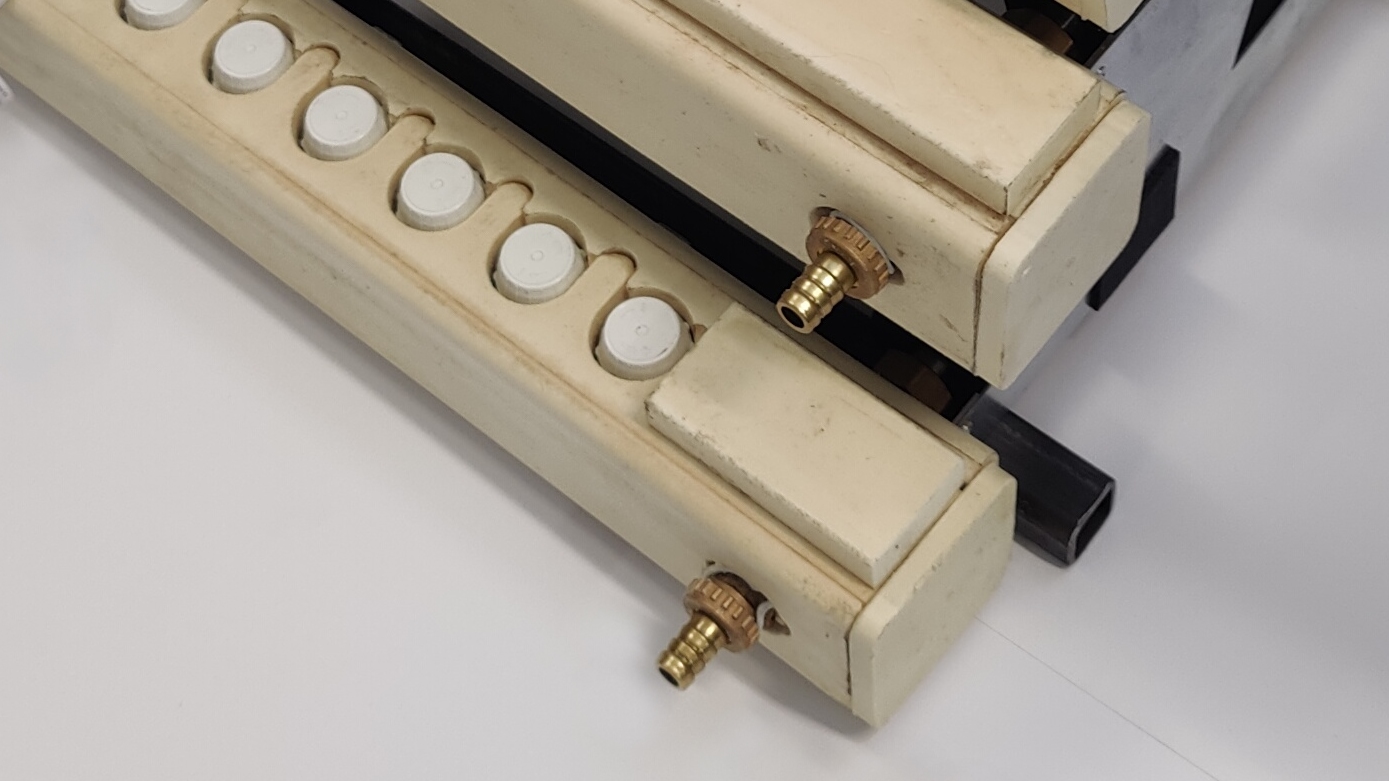

By utilizing PUR, together with the wind industry, we can create specially developed elements that are adapted to specific needs in projects. The flexible material makes it possible to produce lightweight components that at the same time retain strength and durability. This weight saving is particularly important, especially in offshore projects where transport and installation can be challenging and costly.

An exciting possibility with PUR is its potential for recycling. With Dan-isoRECY, Dan-iso can offer the wind industry to develop elements of recycled PUR material, thus contributing to a circular economy where waste is minimized and resources are reused. This is not only an advantage for the environment, but also gives companies the opportunity to offer more sustainable solutions.

The future of the wind industry with PUR

The use of PUR in the wind industry opens up new opportunities for innovation and efficiency. From specially developed lightweight components to sustainable recycling solutions, PUR can be an important part of the wind power projects of the future.

We look forward to working with wind industry experts to exploit the benefits of PUR in future projects. Together we can contribute to a more sustainable and efficient energy future.

Polyurethane products for the wind industry

Let us assist you

Do you have questions or need help? Please do not hesitate to contact us - we look forward to hearing from you.