45 % recycled regenerates

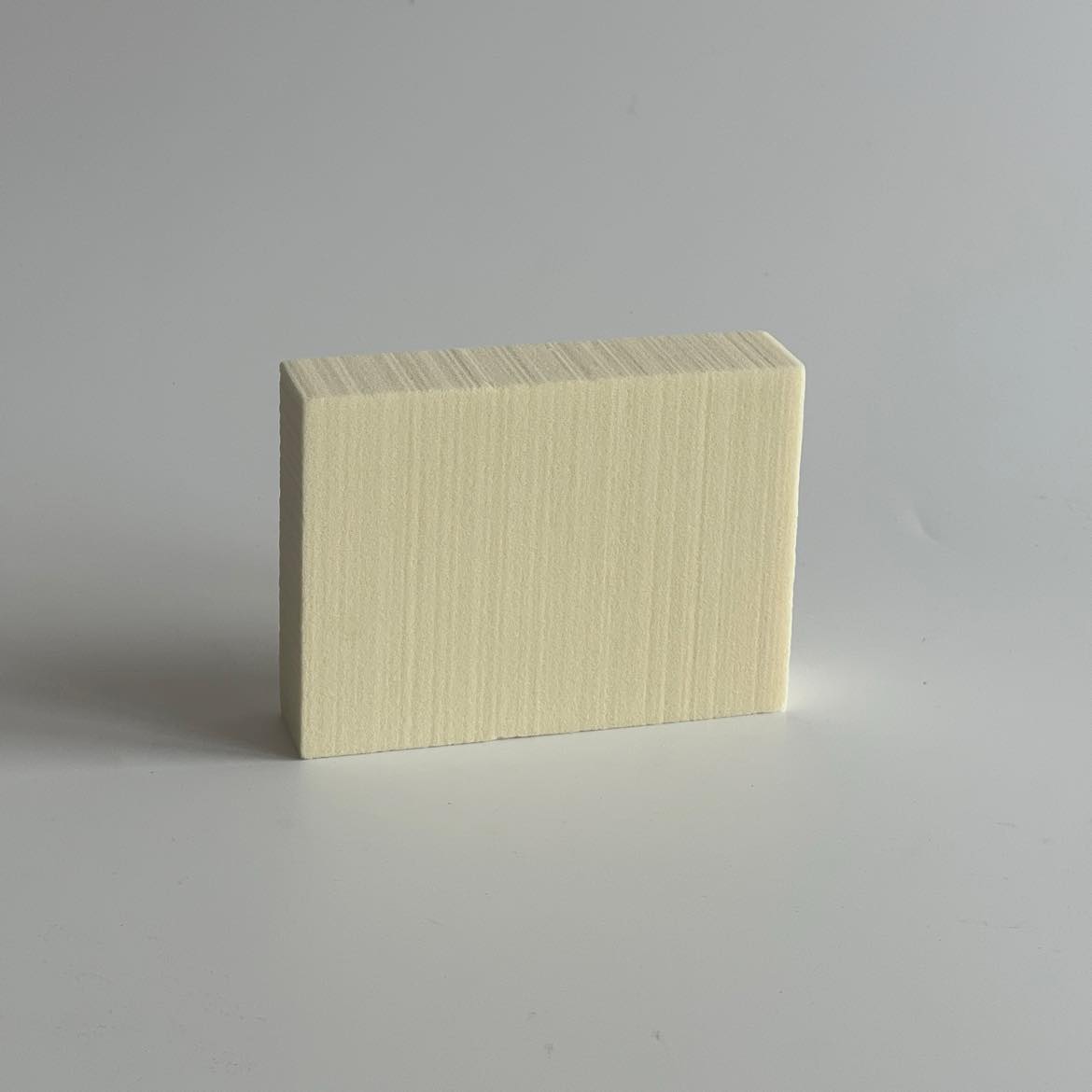

Insulation materials with 45% regenerated

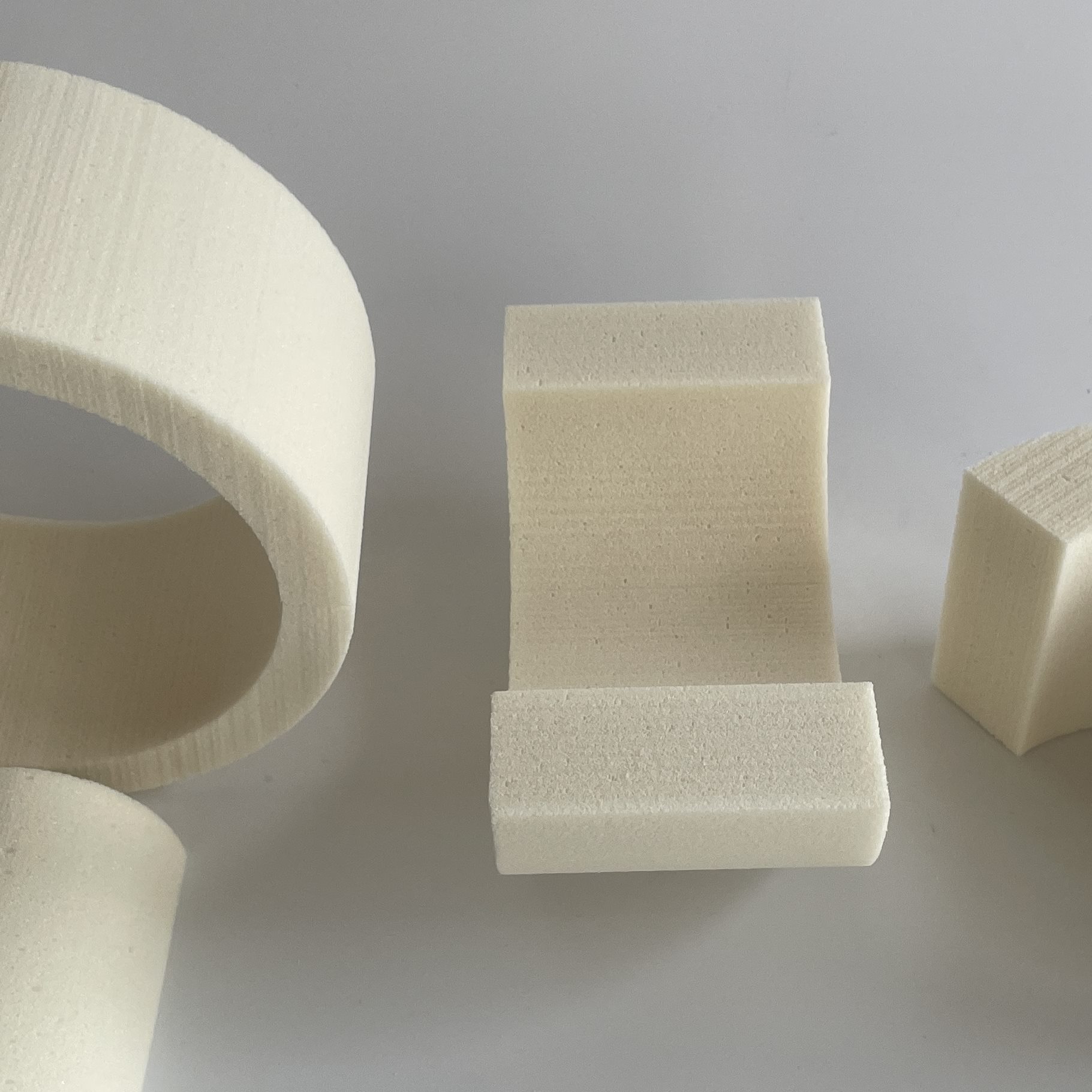

We have created unique results with the recovery of the surplus material from production and can now cast insulation materials with 45% regenerated. Regenerate in the form of hardened PUR, where we recover the production waste and thereby contribute to a more sustainable production.

In the past, it has been associated with very large technical challenges to recover rigid polyurethane foam in a way where the material's most important technical properties are preserved. Industrial recovery of PUR has been minimal and success stories from the industry have been about recycling 2-10 % of the production waste.

From waste to technical insulation

Formidable insulating ability and long life

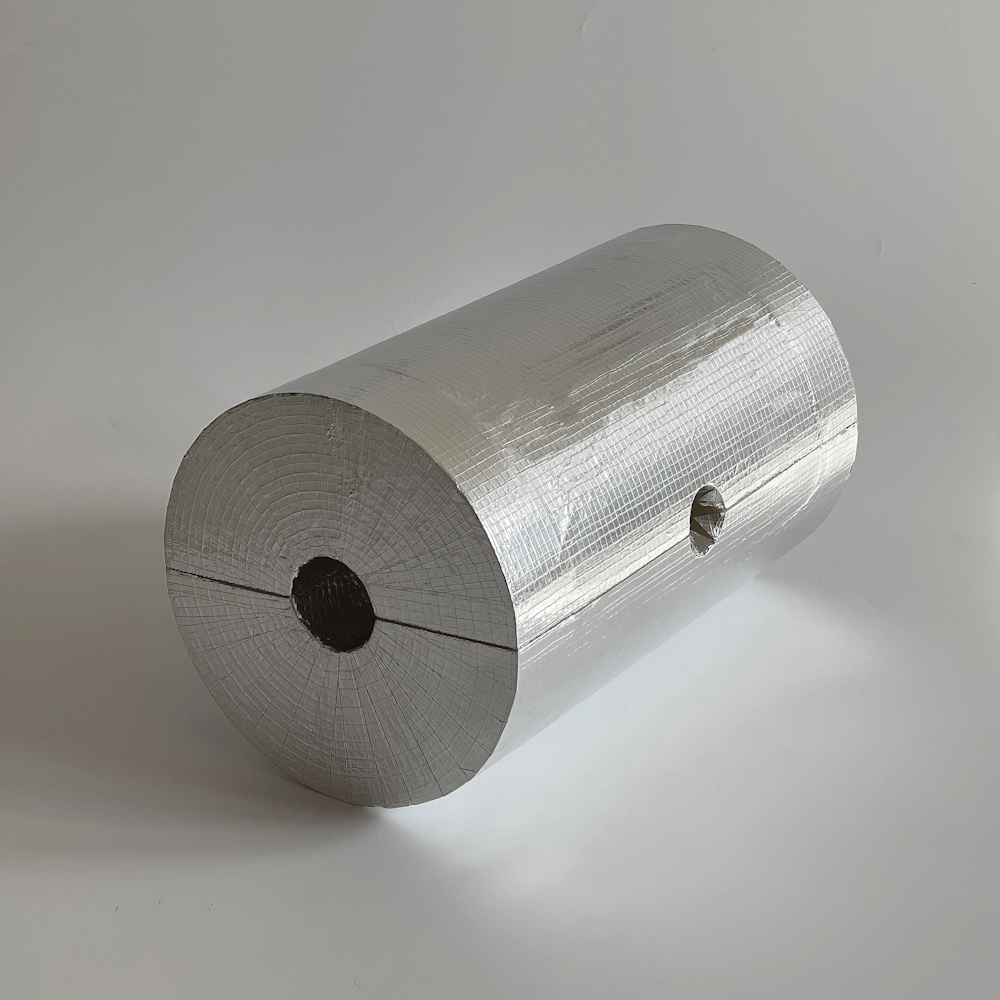

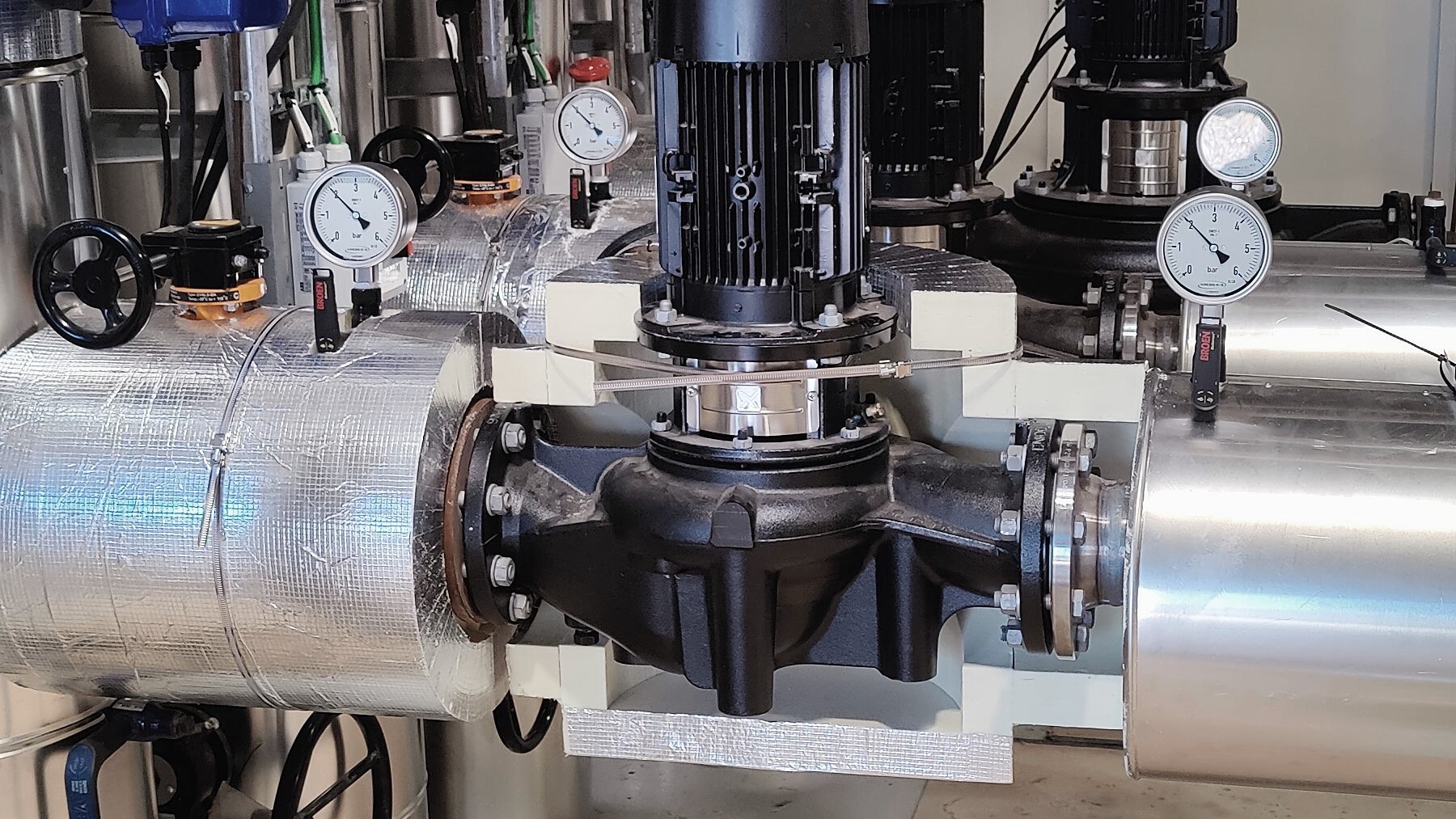

In the green transition, there has been an increased focus on the importance of insulating technical installations. It costs energy to heat up liquids and correspondingly to cool them down. Effective insulation of the piping is therefore an important ingredient in the recipe for more sustainable production and operation.

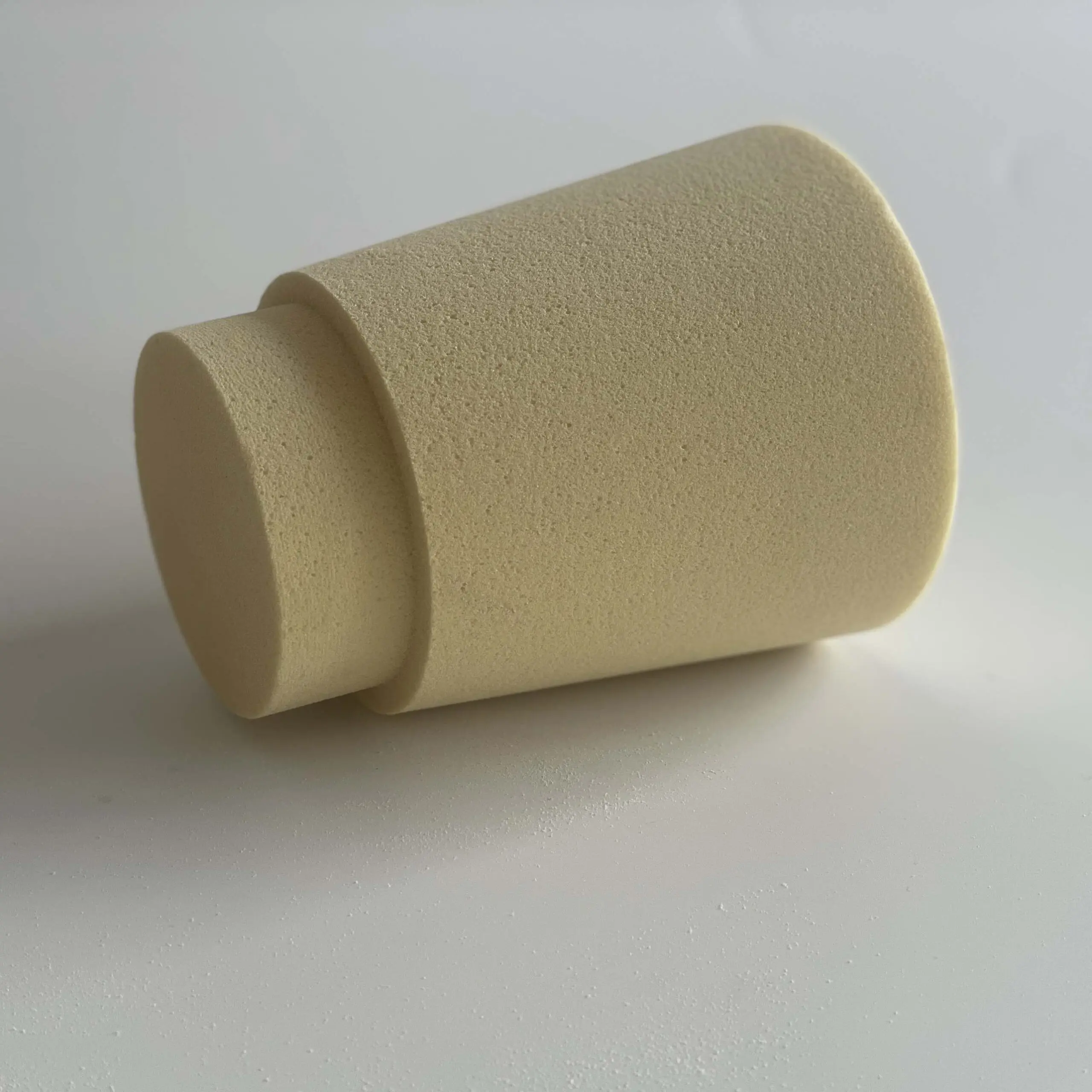

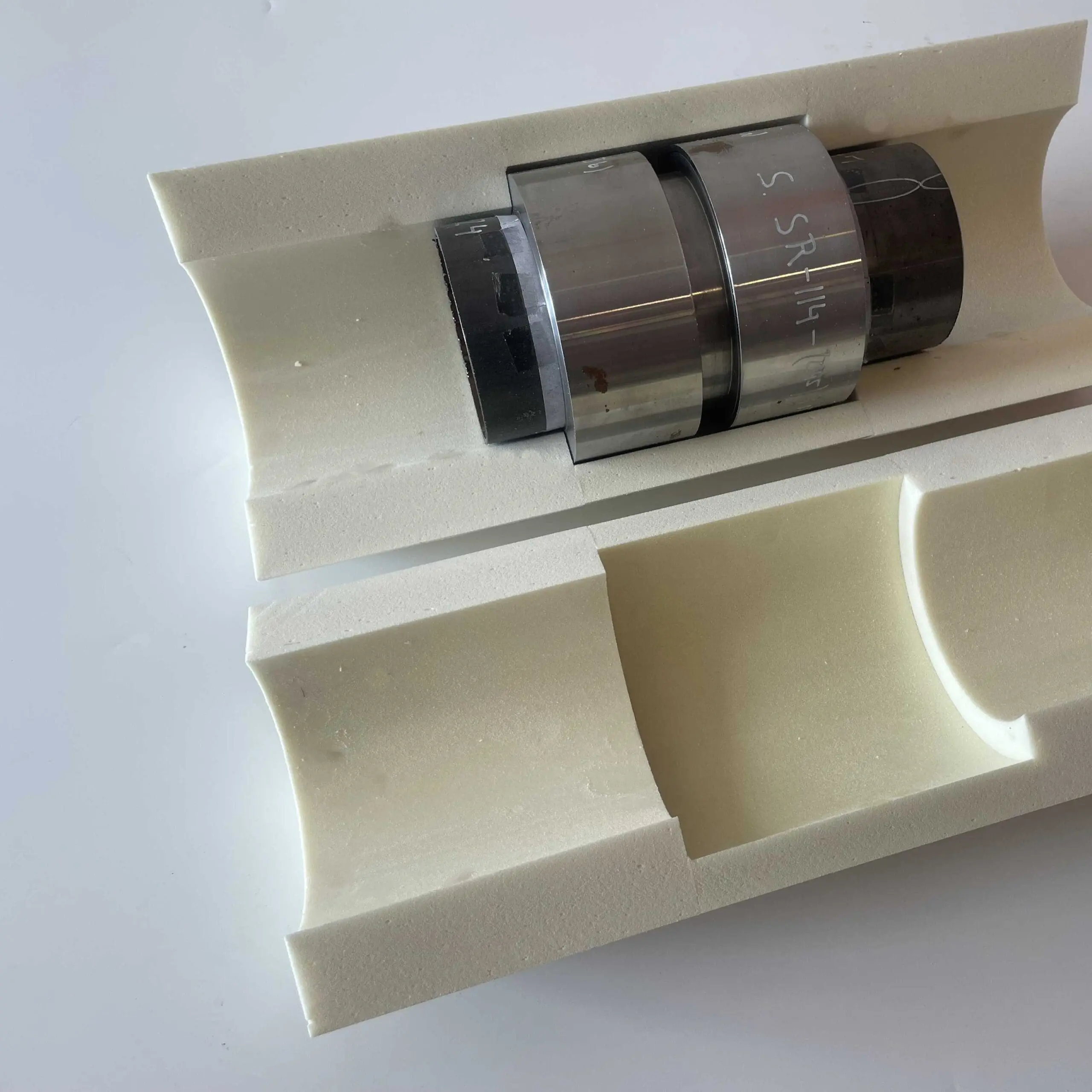

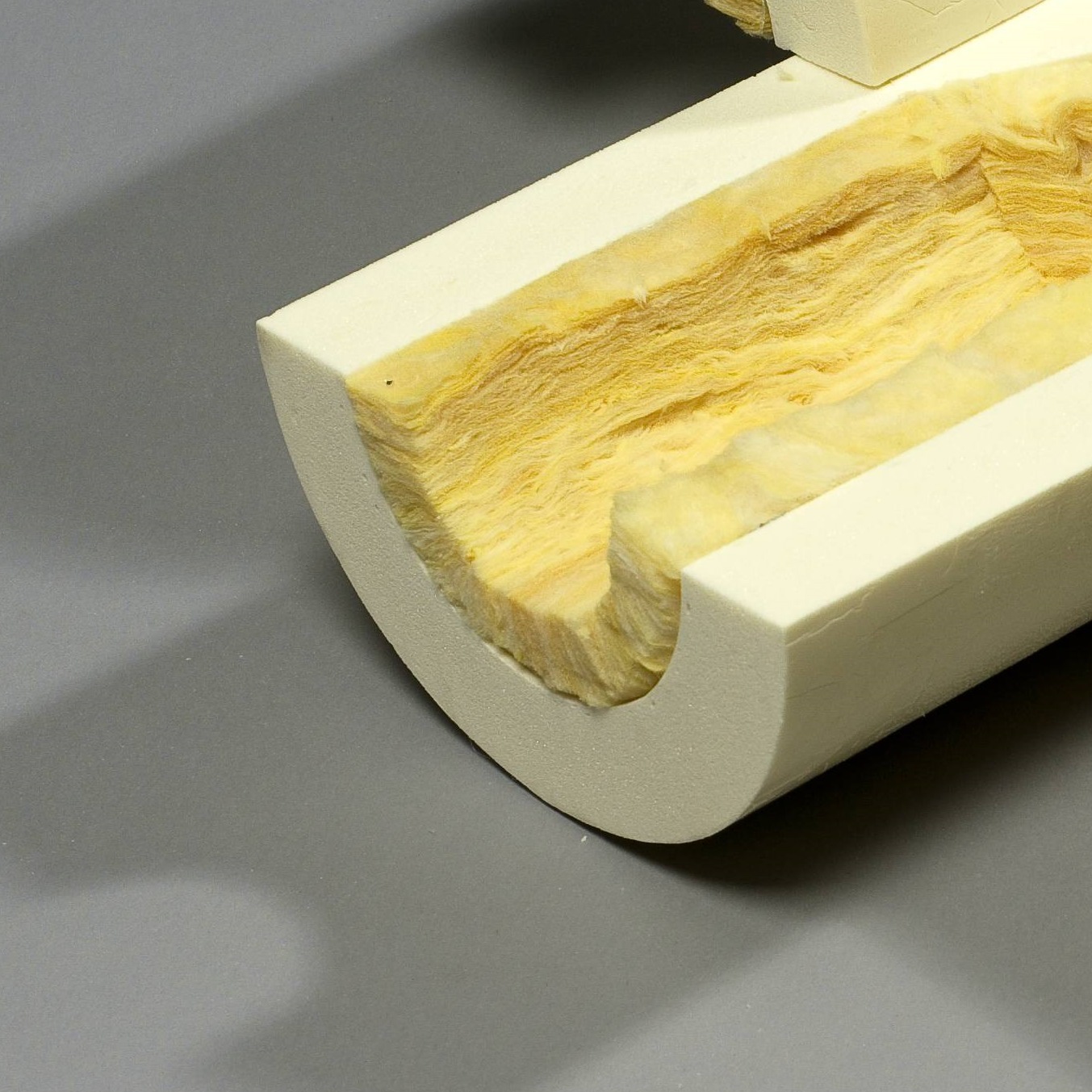

Pipe insulation in cell foam in the form of PUR and PIR has a formidable insulating capacity and a long life, as it does not absorb moisture or collapse. When using PUR and PIR insulation, the loss of heat and cold is reduced far more effectively than with classic insulation types, which saves the world from unnecessary CO2 emissions.

Polyurethane products

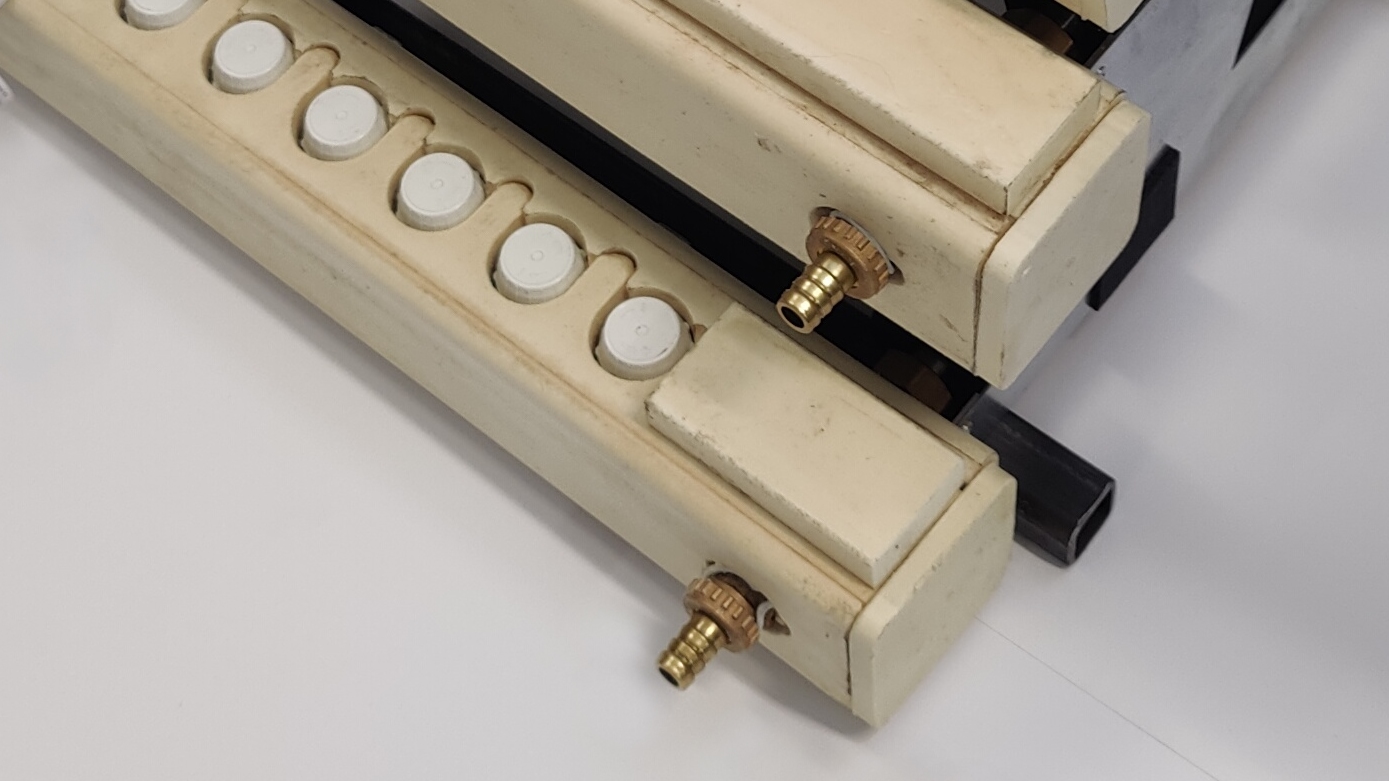

Recycled insulation that saves space

Recycling of surplus material

We have created unique results with the recovery of the surplus material from production and can now cast insulation materials with 45% regenerated. Regenerate in the form of hardened PUR, where we recover the production waste and thereby contribute to a more sustainable production.

Technical challenges

In the past, it has been associated with very large technical challenges to recover rigid polyurethane foam in a way where the material's most important technical properties are preserved. Industrial recovery of PUR has been minimal and success stories from the industry have been about recycling 2-10 % of the production waste.

Success with upcycling

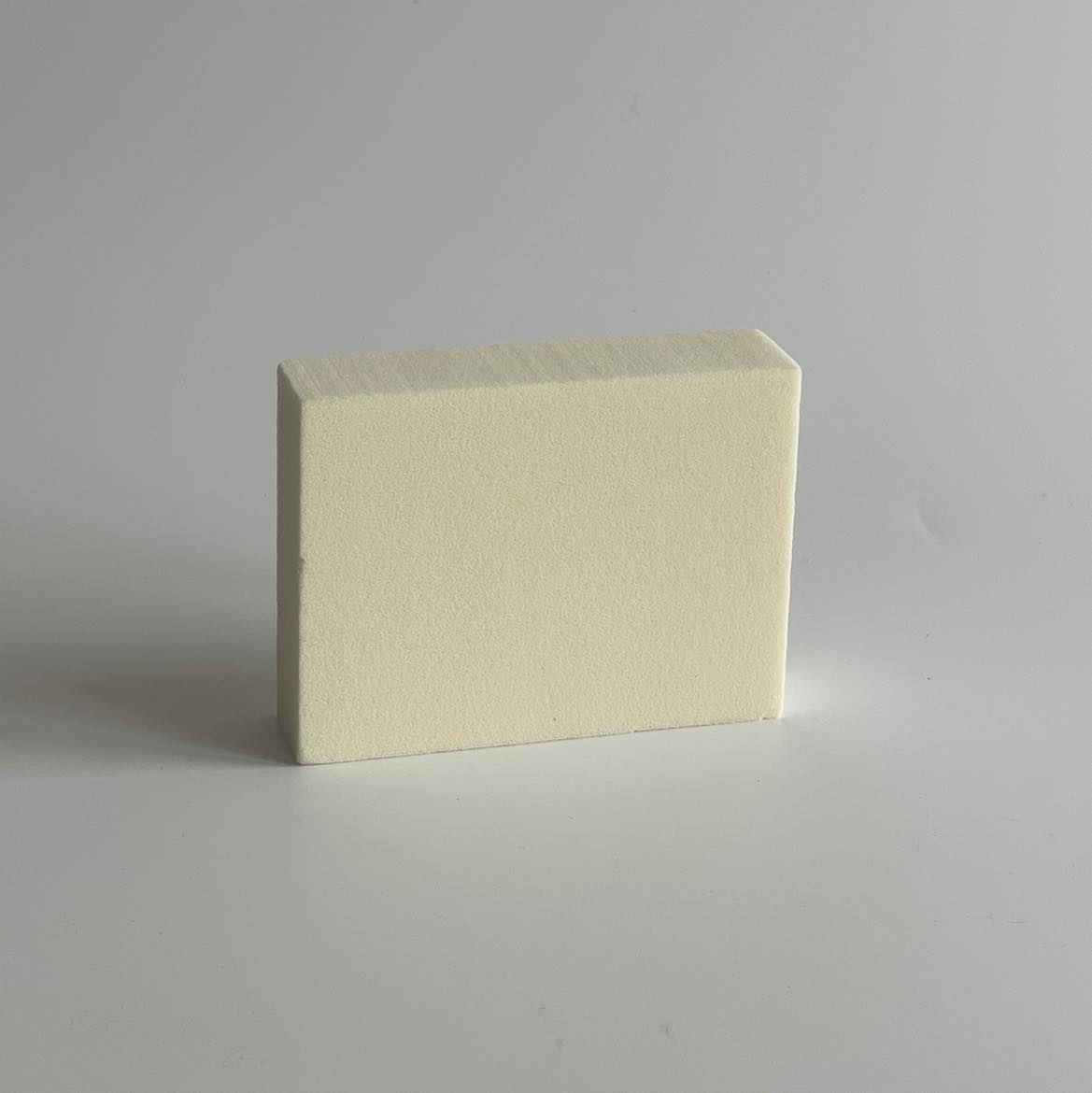

Our success with upcycling is the result of an intensive development process, where reducing residual products and giving new life to waste has been the primary objective. In the process, we have worked with 2 methods, which have given good results. The one technology is now ready to be implemented in production and deliver greener insulation. With the latest results, it has thus been possible to cast products with a high degree of recycling, which at the same time have fully equivalent insulation value and material properties as ordinary molded PUR.

Work with polyurethane foam

Advantages of Rigid Polyurethane Foam (PUR Foam)

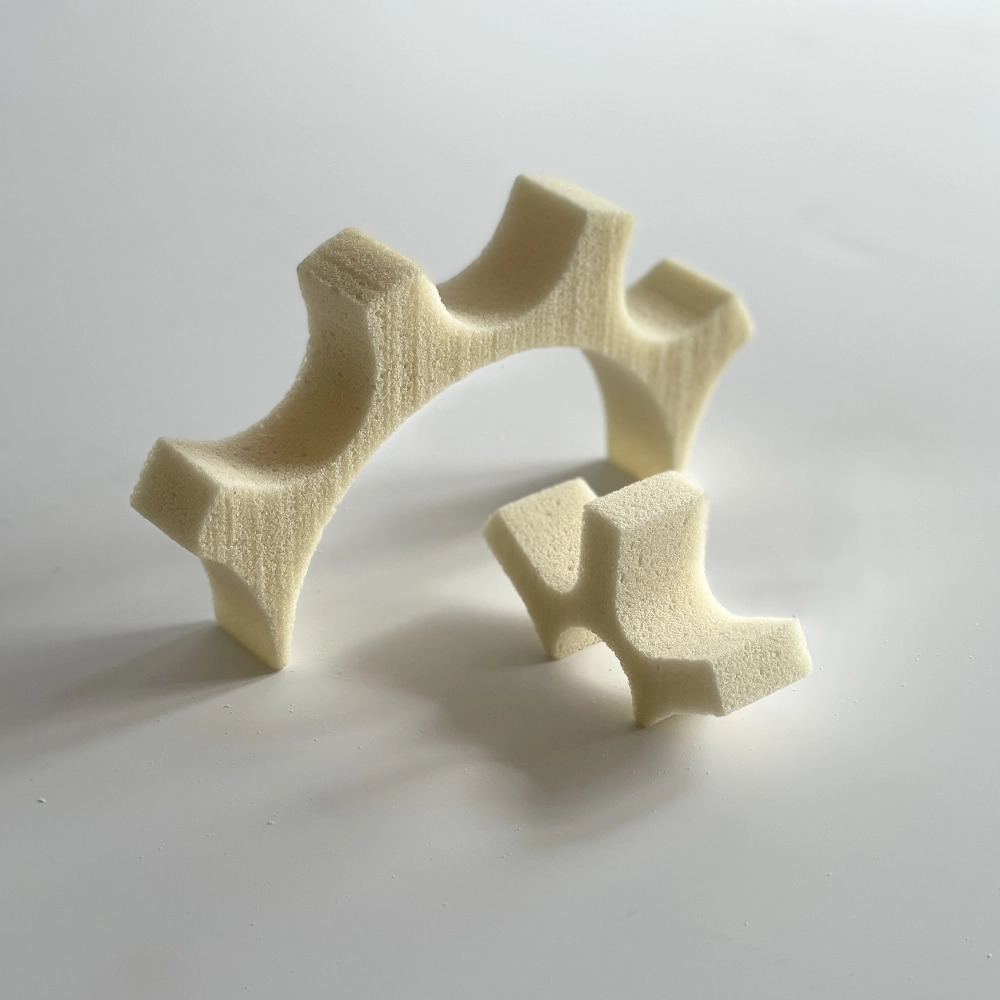

Rigid polyurethane foam (PUR foam) is a thermosetting plastic known for its safe handling and use. The material has several advantages that make it a popular choice in industrial and construction engineering applications. One of the most notable features of rigid PUR foam is its ease of handling. It can be easily cut, shaped and adapted to different applications without the need for advanced equipment or technical skills. This feature makes it ideal for both DIY projects and professional applications.

PUR foam is also known for its low weight in relation to its strength and insulating properties. This makes it easy to transport and install, while providing excellent insulation. It is ideal for insulating walls, ceilings, floors in buildings, as well as pipes and technical installations.

Resilience and Energy Efficiency

An important advantage of rigid PUR foam is its resistance to moisture and mold growth. This feature makes it a reliable choice in wet rooms and other environments where humidity may be a concern. Finally, PUR foam is known for its energy efficiency. It provides excellent thermal insulation, which helps to reduce energy consumption and maintain comfortable temperatures indoors. This makes it a greener choice, as it can help reduce energy consumption and CO2 emissions.

Overall, rigid polyurethane foam is a versatile and reliable material that combines ease of handling, strength, insulation and durability. A favorite in the building and construction industry, it provides effective solutions for a wide range of applications.

Safety when foaming polyurethane foam

Safety measures when working with polyurethane

Working with ready-made foam does not require any special safety measures. However, this is not the case when working with polyurethane foam.

Foaming polyurethane involves mixing the raw materials isocyanate and polyol to produce polyurethane foam. From 24 August 2023, appropriate training will be required before industrial or commercial use of products containing more than 0.1% by weight of isocyanates.

Training requirements and courses for safe working with isocyanates

Only persons who have undergone special training may work with polyurethane foaming. The education is offered by institutions for vocational education, such as AMU centers and technical schools.

Employers or self-employed persons who use the products themselves or weld must also have undergone the training before starting work. Everyone who works with isocyanate must complete a two-day course.

In addition, all employees who work with isocyanates and have an increased risk of being exposed to the substance must complete a new AMU course on personal safety. The course lasts 1 day.

Reviewed courses and announcements at Dan-iso a/s

Only persons who have undergone special training may work with polyurethane foaming.

Everyone who works with isocyanate must undergo a two-day course. In addition, all employees who work with isocyanates in a way that may involve an increased risk of being exposed to the substance must in future complete a new AMU course on personal safety. The course has a duration of 1 day.

We have reviewed the following:

- Personal safety when working with epoxy and isocyanates

- Personal safety with isocyanates with increased risk

- Work with epoxy and isocyanate-containing products

- Appendix 3 to the Norwegian Working Environment Authority's order no. 381 of 12 April 2023 on work with substances and materials (chemical agents)

Let us assist you

Do you have questions or need help? Please do not hesitate to contact us - we look forward to hearing from you.