Block foam

Block foam – a versatile and dimensionally stable foam material

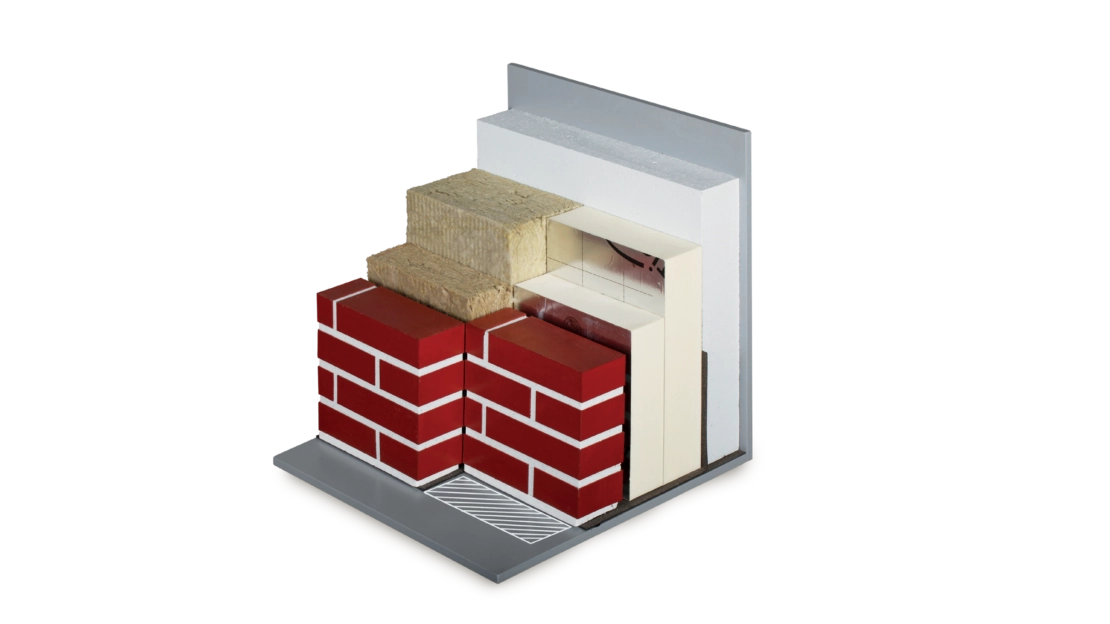

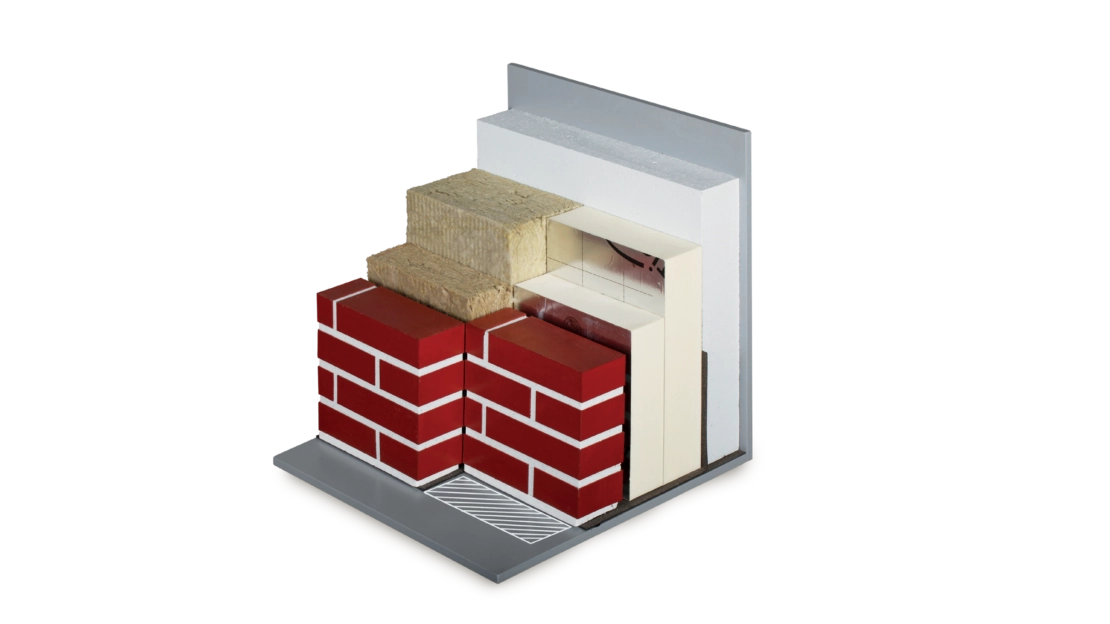

Block foam is an industrially manufactured polyurethane foam that is produced in large blocks that can then be cut, shaped or processed into a wide range of products. The material is characterised by its combination of low weight, high dimensional stability and good insulating properties, making it suitable for both technical and structural purposes. Block foam can be customised in density, strength and structure to meet specific requirements in everything from thermal insulation and technical components to packaging and industrial solutions. The flexible production makes it possible to create uniform materials with precise dimensions, while the foam maintains a stable performance over time. This makes block foam a reliable choice in many different industries where quality, durability and precision are essential.

Products

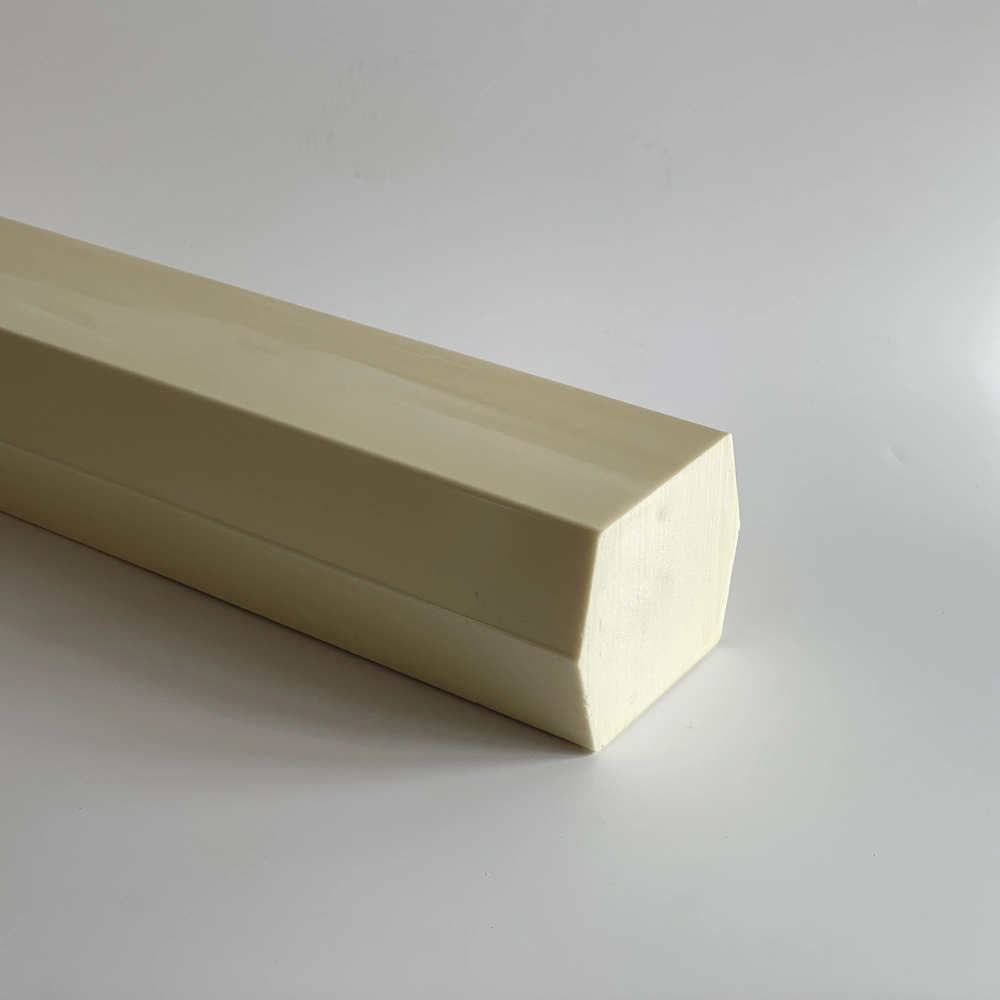

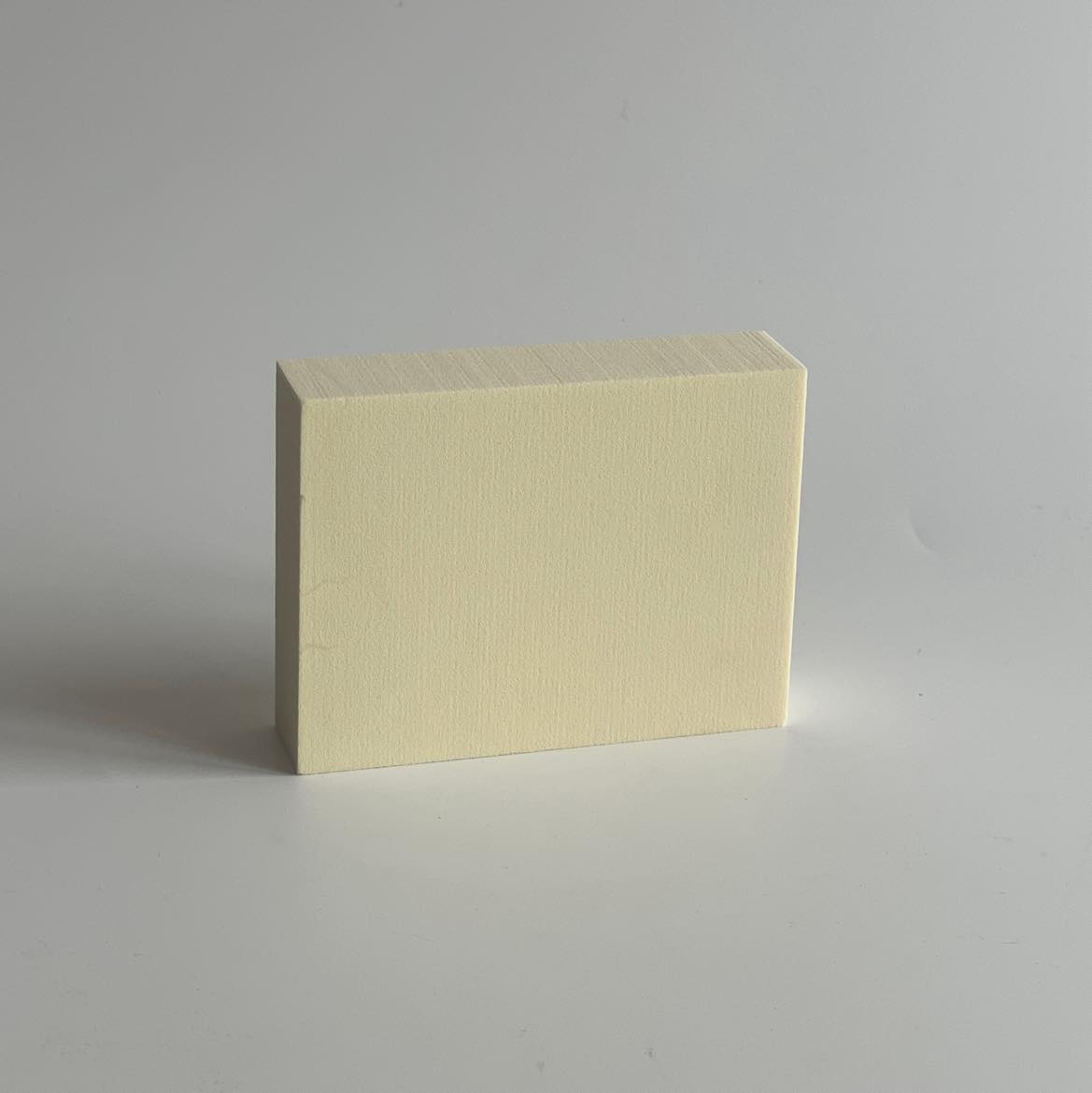

PUR block foam

Dan-iso produces PUR block foam with densities of 35 and 60 kg/m³, allowing for both lightweight and heavier solutions. Our molded blocks can be cut and machined precisely with contour saws or on a 5-axis CNC mill, to suit even complex and bespoke projects.

With a stock of block foam, we can ensure fast delivery and efficient project implementation. PUR block foam combines high strength, insulation and durability, making the material ideal for technical installations, construction projects and industrial applications.

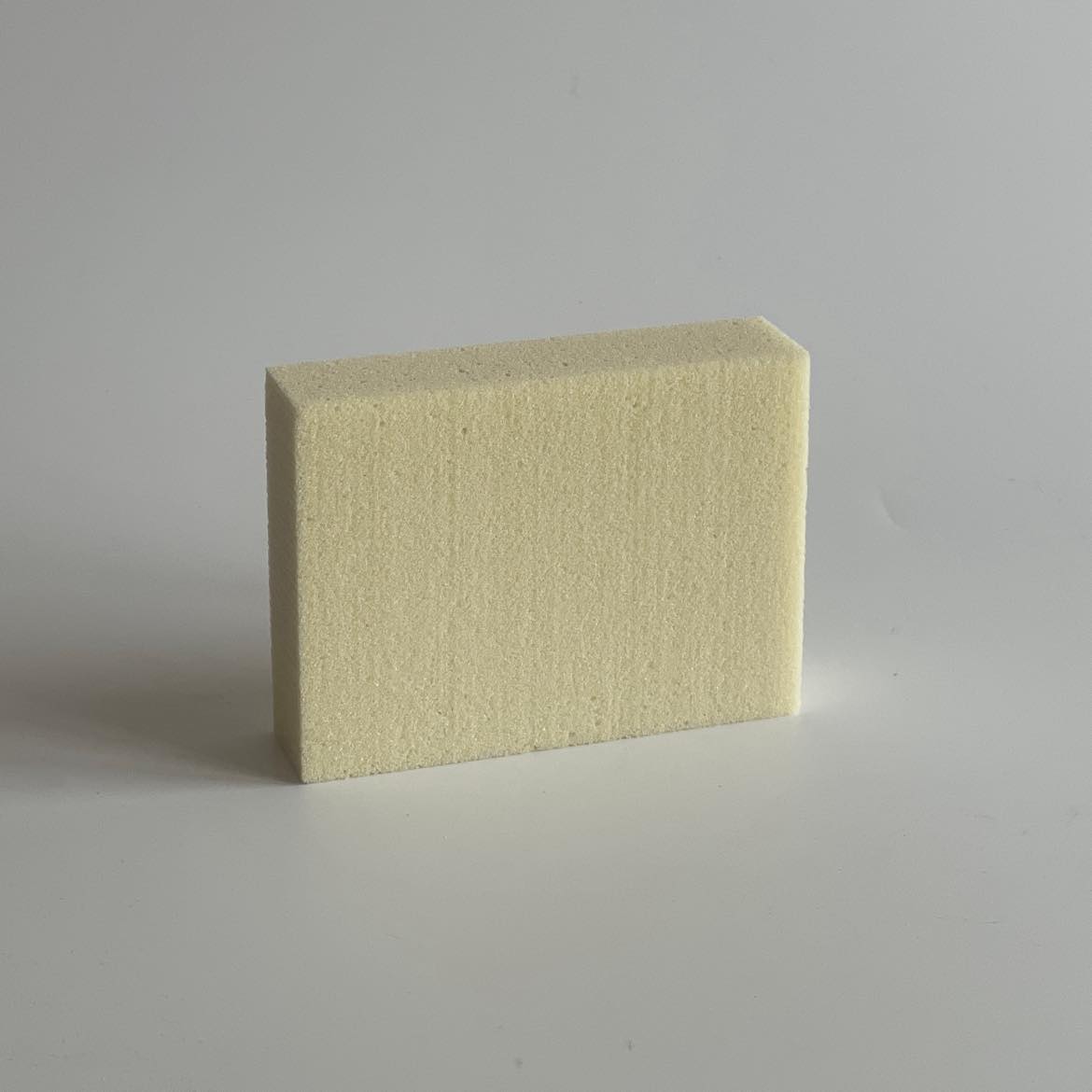

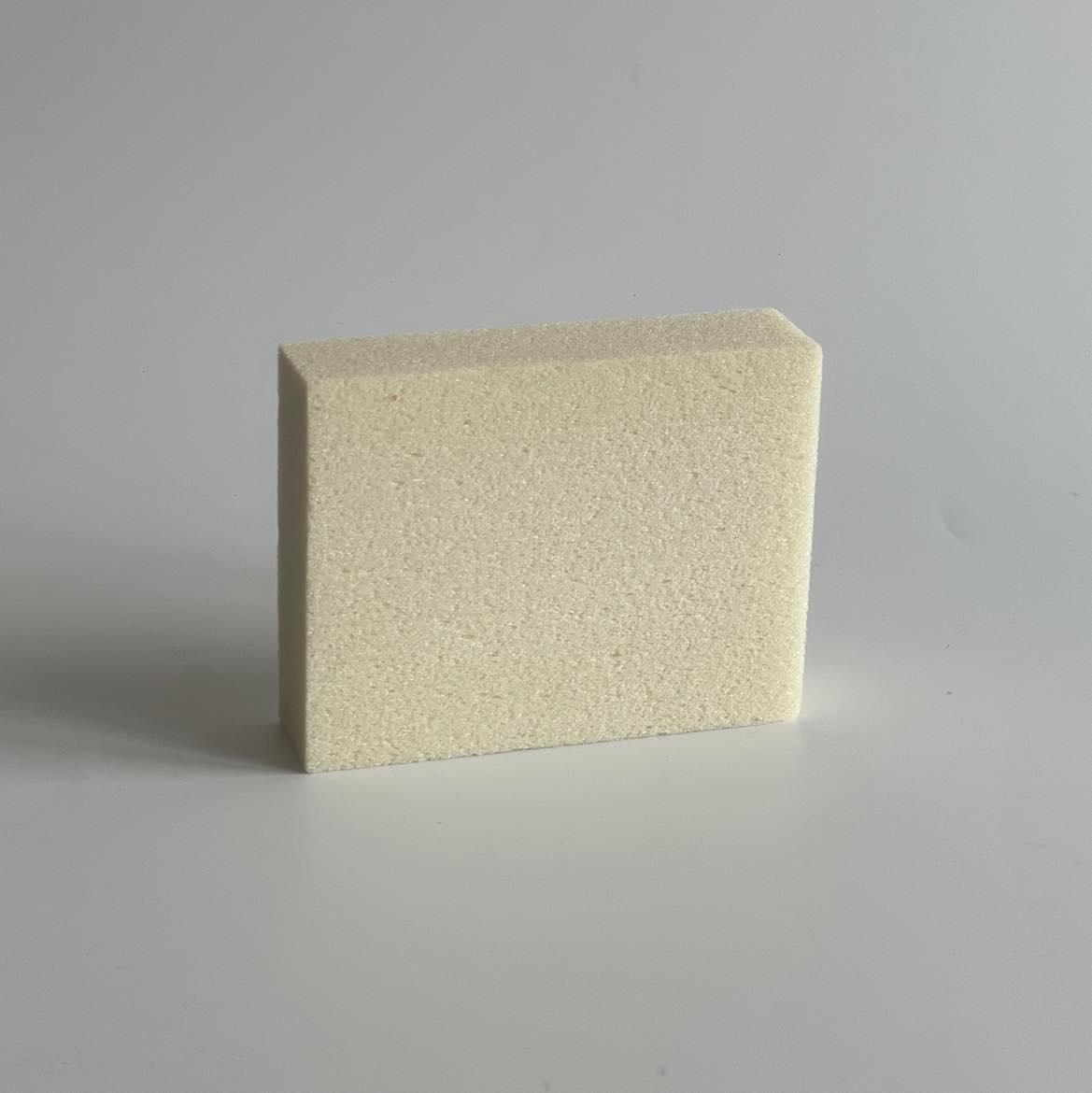

Block foam PIR

Dan-iso produces high-quality PIR blocks with densities of 57, 80, 100, 145 and 200 kg/m³, allowing for tailor-made solutions for projects with different requirements for strength, insulation and fire safety. The materials are ideal for technical installations, custom-designed items and construction projects where precision, safety and stability are essential.

With our contour saws and 5-axis CNC routers, blocks can be processed and cut precisely according to specific needs, so that both form, function and design can be adapted to the project's requirements.

PIR block foam has high temperature resistance, low flammability and meets Euroclass E fire approvals according to ISO 11925-2. With blocks in stock, we ensure fast delivery, while the materials' insulation capacity, strength and fire safety always meet professional standards.

Products

Advantages of PUR block foam

Lightweight and strong

PUR block foam combines low weight with high mechanical strength, making the material easy to handle without compromising load-bearing capacity. This makes it suitable for block-building, support and technical installations.

Flexibility and adaptation

The blocks can be cut, shaped and machined precisely with contour saws or CNC routers, making it possible to tailor solutions for specific tasks and complex projects.

High insulation capacity

PUR block foam also functions as an insulation material. It helps reduce heat loss, improve energy efficiency and contribute to stable temperatures in installations and structures.

Long life and durability

The material is resistant to moisture, pressure and temperature fluctuations, ensuring long-lasting performance and minimal maintenance.

Fast delivery and availability

PUR block foam can be stocked in various sizes and densities, allowing it to be quickly delivered and used in projects of all types.

Advantages of PIR block foam

PIR block foam combines high insulation performance with low thickness, meaning it can achieve the same thermal performance as other materials but takes up less space. This makes it ideal for projects where space is limited but where effective insulation and stable support are still essential.

The material has high mechanical strength and long durability and is resistant to moisture, pressure and temperature fluctuations. PIR block foam also has low flammability and meets Euroclass E fire requirements, making it suitable for technical installations and construction projects with high safety requirements.

The blocks can be cut and machined precisely with contour saws or CNC routers to suit both standard and complex applications. The combination of space-saving thickness, high strength and fire resistance makes PIR block foam an efficient and safe solution.

A strong and flexible solution for shoring and support

PUR and PIR blocks and beams are an effective solution for shoring and support in both construction and installation projects. The materials combine low weight with high strength, making them easy to handle and at the same time stable enough to support even heavy installations. They are suitable for many types of tasks – from piping to technical installations – and provide safe and durable support wherever they are used.

Advantages of PUR and PIR blocks and beams

One of the biggest advantages is the good ratio between weight and strength. PUR and PIR are easy to work with, but at the same time have the necessary load-bearing capacity for both pipes, equipment and structural parts. The materials can be easily cut and shaped to fit the task at hand, making them very flexible in use. At the same time, they have a high insulation capacity, which can be valuable in projects where temperature control and energy efficiency play a role.

Long life and high resistance

PUR and PIR are known for their durability. They withstand moisture, pressure, vibrations and large temperature fluctuations, making them ideal for installations that must function stably for many years. The long service life means less maintenance and fewer replacements – a clear advantage in both major construction projects and daily operations. The materials retain their dimensional stability and insulating ability over time, even under demanding conditions.

Areas of application and dimensions

The blocks are used, among other things, for blocking pipes, where correct height and support are crucial, and for technical installations such as ventilation, heating and cooling systems. In construction projects, they function as additional support in floors, ceilings and walls. At Dan-iso, PUR blocks are supplied in sizes up to 2500 × 1200 × 680 mm, and the tolerance depends on the type – from +/- 1 mm to a maximum of +/- 2 mm. This provides great flexibility when the solution needs to be adapted precisely to the project's requirements.

Do you have any questions?

Send us your contact information and we will contact you as soon as possible.