Technical insulation ensures precision, performance and long life

- Protects the flow meter's sensitive electronics from overheating

- Ensures the flow meter has the required high accuracy

- Longer life of the electronics in and around the device

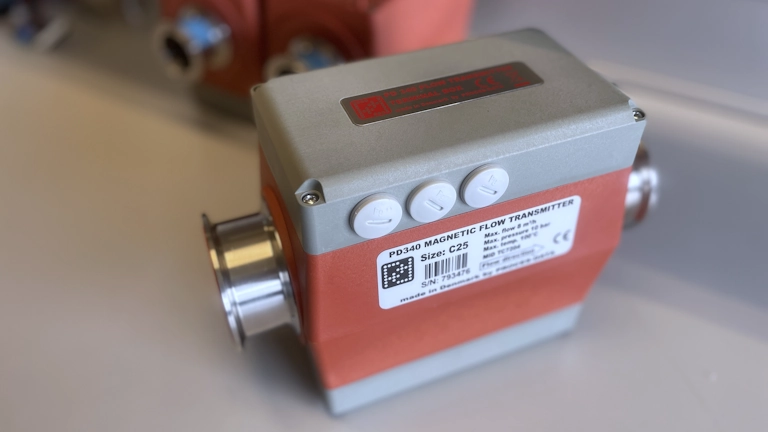

When electronics and precision technology meet in demanding environments such as the food industry, data centers, etc., thermal insulation can play a central role. This is the case, for example, at PROCES-DATA A/S in Silkeborg, where the company develops and produces magnetic inductive flow meters for the food industry as well as other sectors.

Read on after gallery…

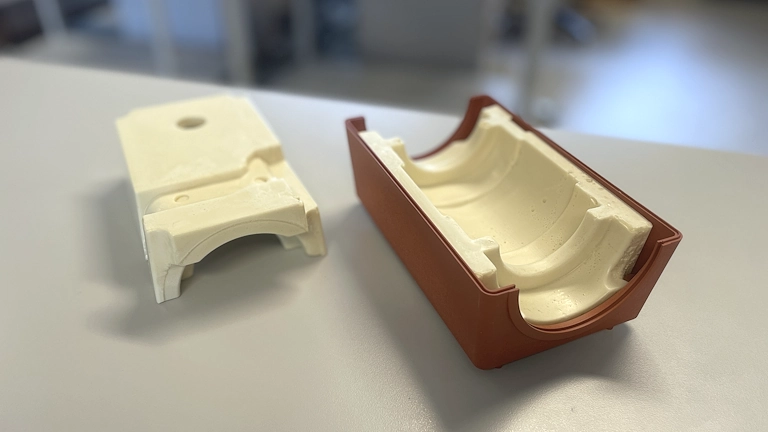

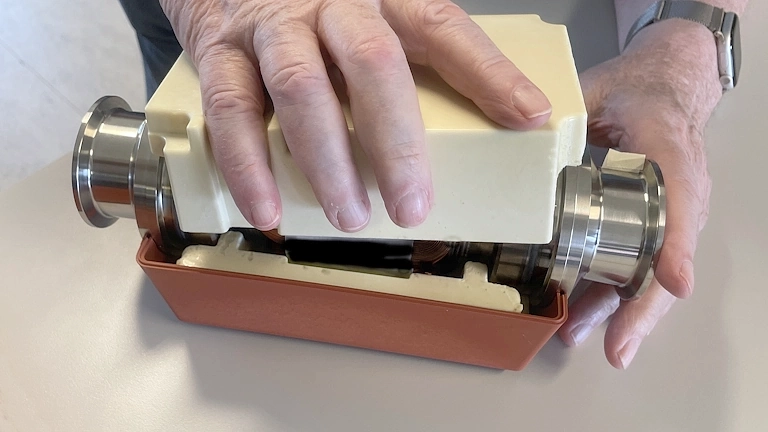

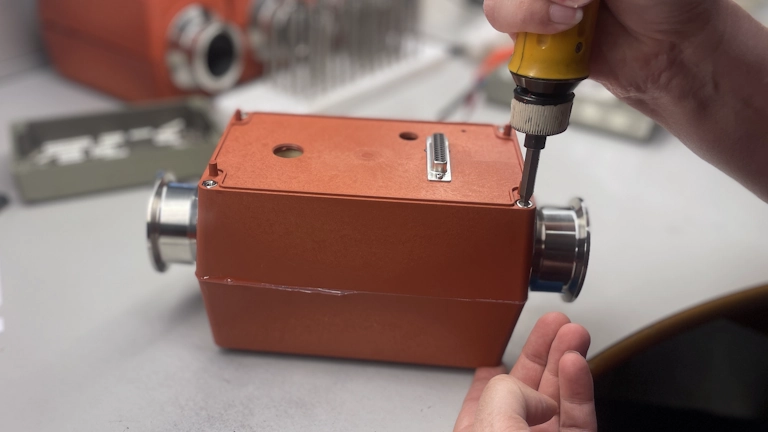

Dan-iso supplies the molded PUR insulation solution that protects the flow meter's electronics from overheating. The pre-molded polyurethane shells are produced on molds developed in close collaboration with Proces-Data – and are adapted to their precise requirements and specific production methods.

"The flow meters work with high accuracy – often with deviations of only a few parts per thousand – and are designed to measure flow in liquids at temperatures of up to 130°C. At the same time, the unit contains very sensitive electronics that must not exceed 85°C. Here, the technical insulation is absolutely crucial to maintaining a stable, controlled temperature – and thus ensuring not only accuracy but also a longer lifespan of the electronics in and around the unit.", explains Hans Madsen, PROCES-DATA A/S.

A technical partner for the needs of the future

The molded PUR solution insulates and protects and is an integral part of PROCES-DATA's flow meters. As in many other advanced applications with sensitive electronics such as those used in dairies, breweries, the pharmaceutical industry, data centers and other industries, effective temperature control is essential for the core products of industries as well as improving the precision and lifespan of technical applications.

“We experience great cooperation from Dan-iso, and they listen to our specific wishes – including that we want to deliver the molds for production ourselves,” says owner and founder Ole Cramer, PROCES-DATA, and continues, “It is important for us to have a partner who has both the ability and the desire to handle a slightly special product.”

Project: PROCES-DATA A/S

Customized solution in close collaboration

At Dan-iso A/S, we see ourselves as a technical sparring partner within insulation solutions, and contribute knowledge and experience in close collaboration with our customers.

We can participate early in development processes, find solutions to existing challenges and adapt specific insulation solutions so that they fit precisely in geometry and function with high complexity and accuracy requirements.

– this applies to small compact units as well as to PROCESS DATA as well as to large geometries such as centrifugal pumps etc.

Insulating electronics in demanding environments

In many industrial and technical applications, electronics operate in close proximity to fluids under extreme conditions — both at high and low temperatures. In addition to flow meters, this also applies to precision pumps, dosing systems, valve controls, and analytical equipment, where the electronics are either integrated into or located close to components that handle fluids. In such environments, insulation can be crucial to protect against condensation and chemical attack.

Insulation: Simple solution with great effect

By insulating technical applications, heat loss can be significantly reduced, while improving durability, operational efficiency and overall system stability.

Industry analyses show that proper insulation can reduce energy consumption by up to 20–30 %, depending on the type and size of the application.

These savings can be felt directly on the bottom line—especially in energy-intensive industries, where even small improvements in efficiency can have a significant economic impact.

Let us assist you

Do you have questions or need help? Please do not hesitate to contact us - we look forward to hearing from you.