From waste to high-quality insulation with Dan-isoRECY

Effective insulation in recycled materials

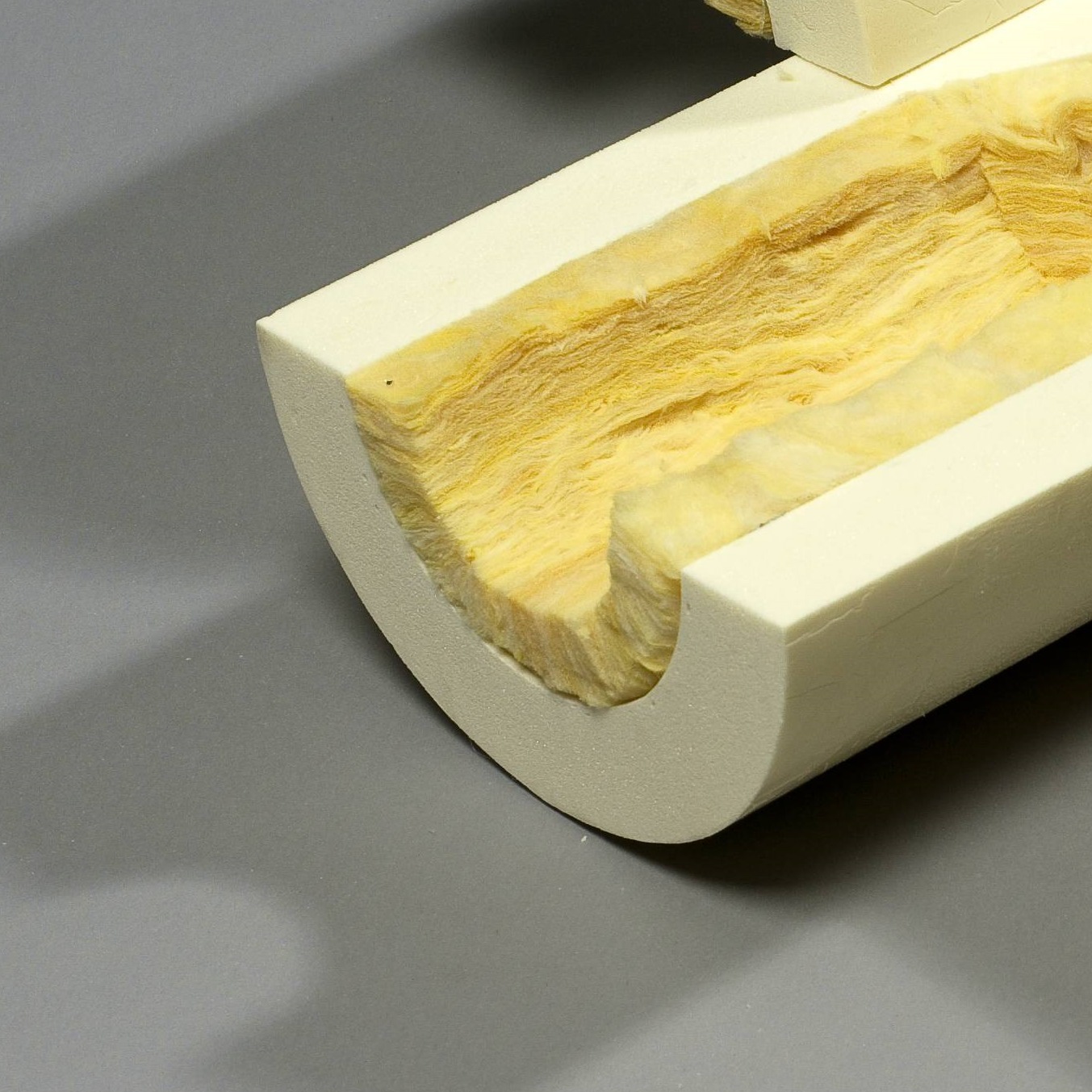

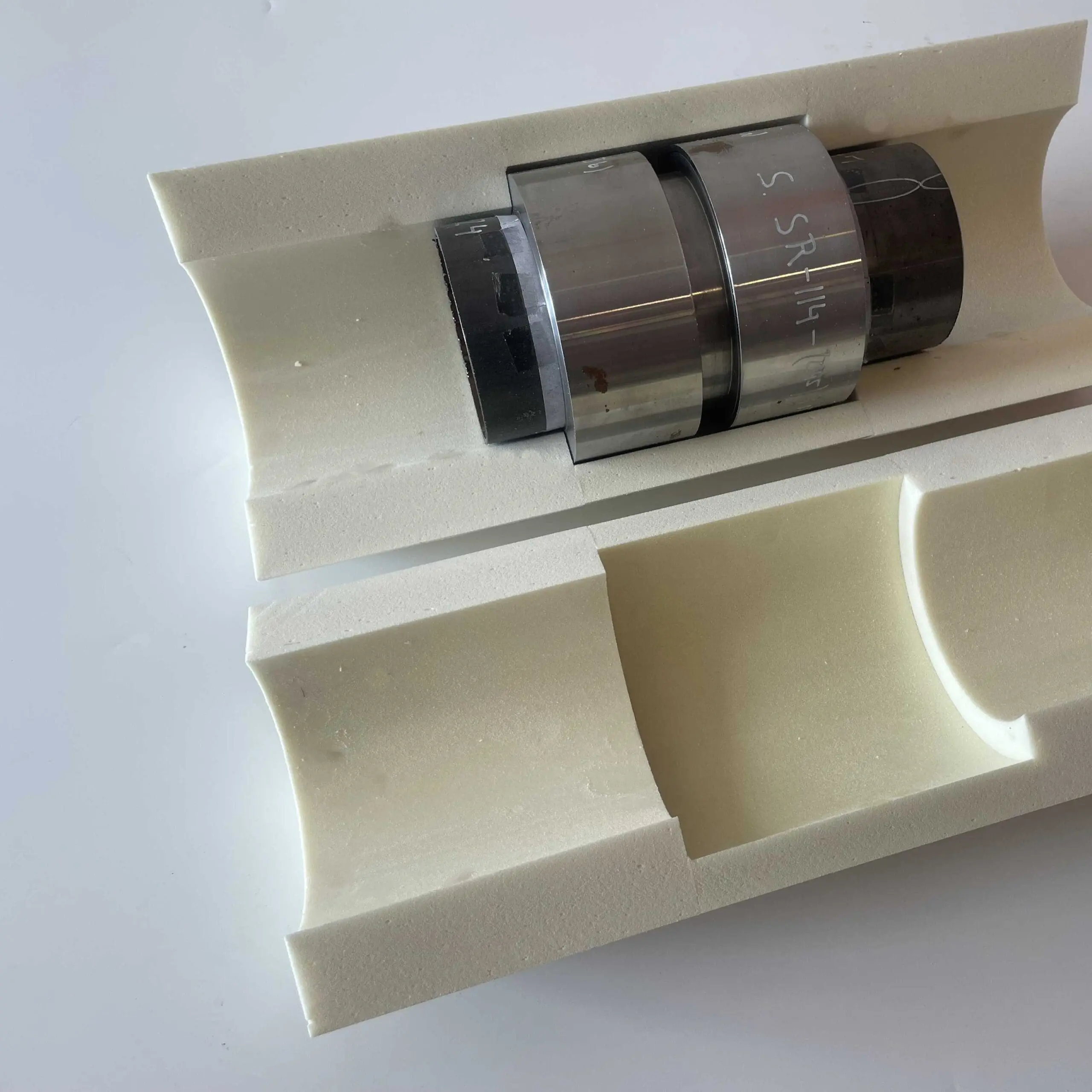

Discover how in our production we have the opportunity to recycle our own PUR waste to create new sustainable insulation solutions from PUR (polyurethane). Our innovative process transforms surplus materials and scraps from our own production into insulation with the same excellent properties as usual, while reducing waste and reducing the need for new raw materials. When you choose our recycled PUR products, you not only get effective insulation with low energy loss, but you also contribute to a greener future with less environmental impact.

45 % recycled material from our own production

We are proud to be able to offer insulation materials that contain up to 45 % regenerated from the surplus material in our own production. This step is an important part of our sustainability strategy, where we recycle and upcycle our waste to create new products. Our innovative methods ensure that the recovered materials maintain the same high insulation value and quality as traditional PUR.

Our success with upcycling is the result of an intensive development process, where reducing residual products and giving new life to waste has been the primary objective. In the process, we have worked with two methods, which have given good results. The one technology is now ready to be implemented in production and deliver greener insulation. With the latest results, it has thus been possible to cast products with a high degree of recycling, which at the same time have fully equivalent insulation value and material properties as ordinary molded PUR.