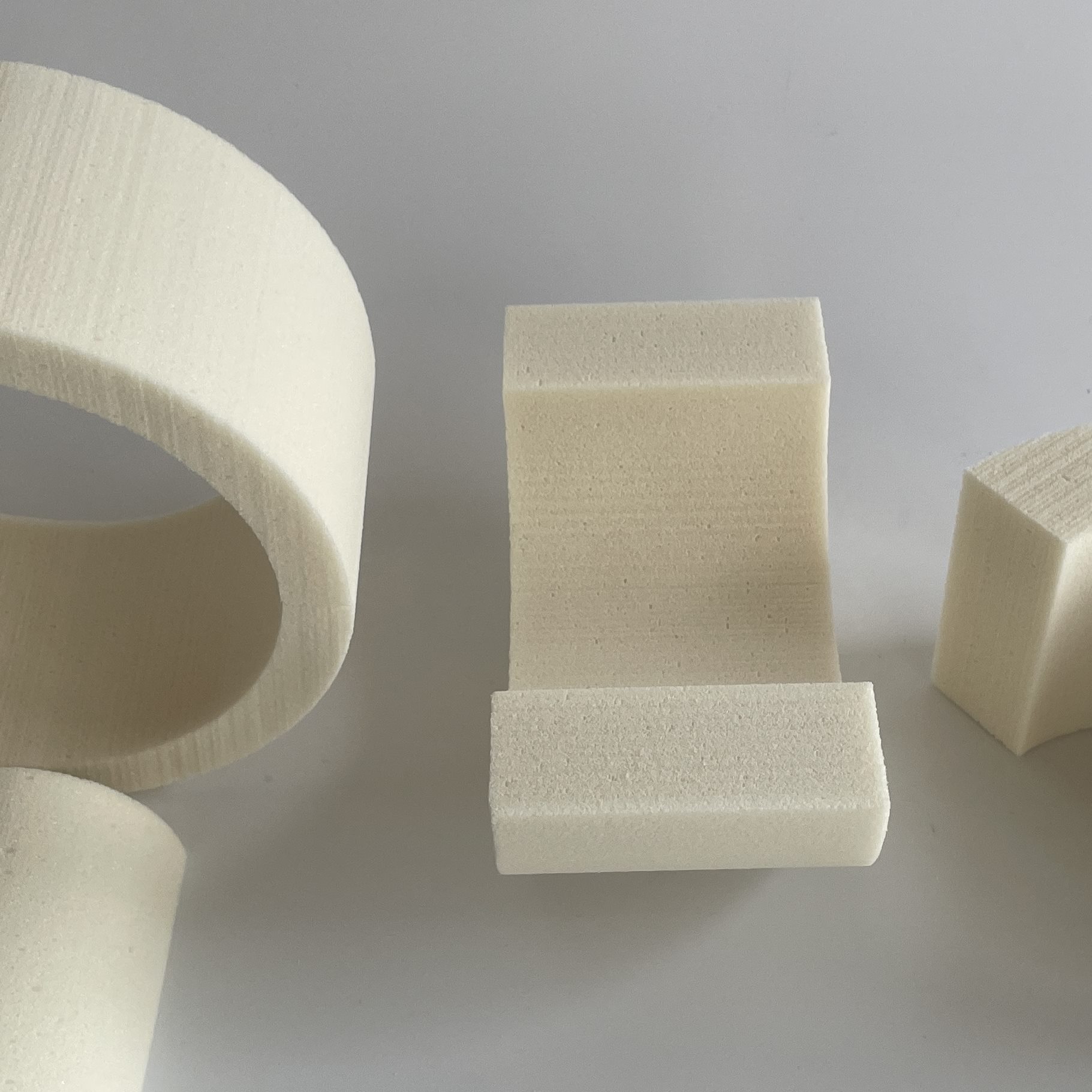

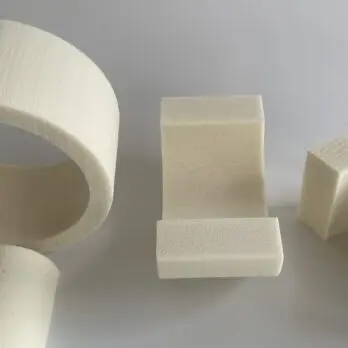

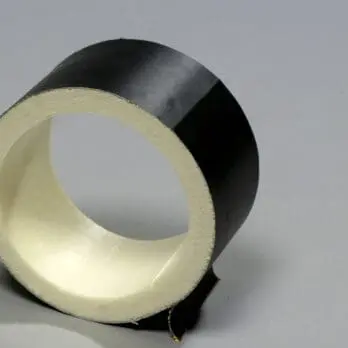

Polyurethane pipe supports and suspension cups

Insulated pipe supports are essential components in industrial insulation where high compressive strength and load-bearing capacity are required.

Advantages of PUR and PIR insulated pipe supports

PIR insulated pipe supports combine high mechanical strength and excellent thermal insulation. They have low thermal conductivity, are resistant to moisture, chemicals and high temperatures, making them ideal for both construction and industrial installations. Their light weight makes installation easy and efficient.

Use in district heating systems and other industries

In district heating systems, PIR supports reduce heat loss, increase energy efficiency and extend the life of pipelines. They are also used in the plumbing, HVAC, refrigeration and chemical industries, where they protect systems and reduce the need for maintenance.

Application

Suspension bowls and pipe supports are essential components in industrial insulation, where high compressive strength and bearing capacity are required.

Here are some of their primary uses:

Technical data sheet

Contact us for further information and product datasheet.

Technical specifications

| Material properties | Value | Standard |

|---|---|---|

| Density (Mean) | 75 kg/m3 | ISO 845 (/DIN 53420-78) |

| Closed cells | > 88% | ISO 4590 |

| Cell size | < 0.5 mm | EN253 5.3.2.1 |

| Water absorption during boiling | Mean 4.4% Vol | EN253 5.3.5 |

| Compressive strength, radial | ≥ 0.40 Mpa | ISO 844 |

| E-Module, radial | ≥ 9.5 MPa | ISO 844 |

| Dimensional stability | ||

| -30°C | 48h: 0.0 % vol. | |

| +100°C | 48h: -1.0 % vol. | (ISO 2796 / DIN 53431-77) |

| +150°C | 48h: -1.4 % vol. | |

| Thermal conductivity | ||

| λ10 | 0.0238 W/m*K | |

| λ20 | 0.0247 W/m*K | ISO 8301 / ASTM C518 |

| λ50 | 0.0284 W/m*K | |

| Fire class | B3 | DIN 4102 Part 1 |