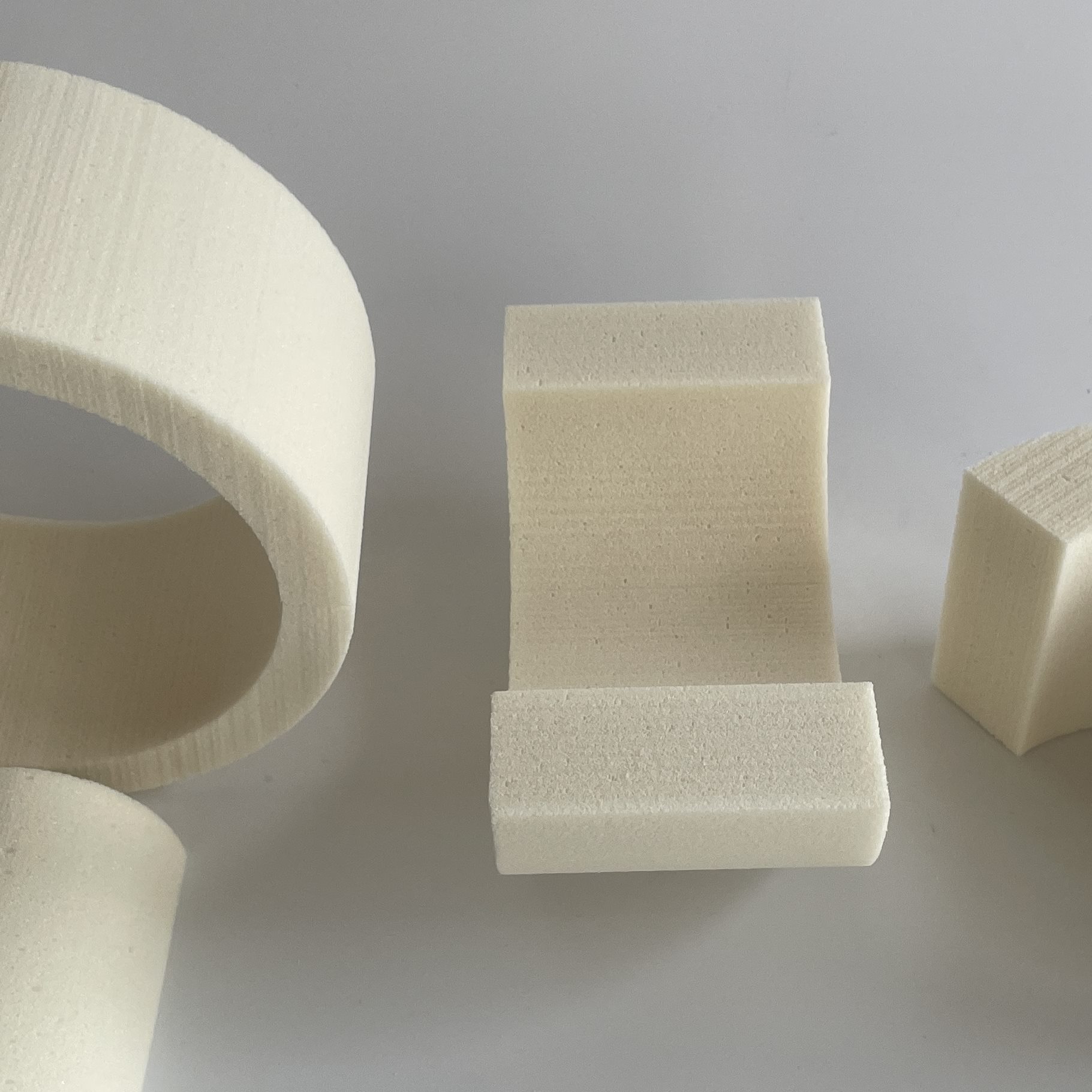

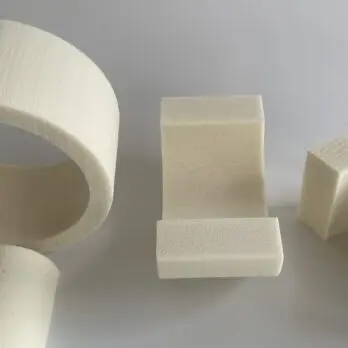

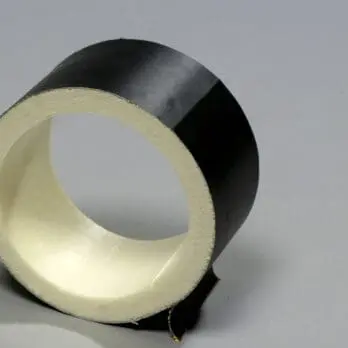

Pipe supports and suspension cups in 60kg polyurethane

Pipe supports in 60kg/m3 are essential components in industrial insulation where high compressive strength and load-bearing capacity are required.

Advantages of PIR-insulated Pipe Supports

PIR insulated pipe supports combine high mechanical strength and excellent thermal insulation. They have low thermal conductivity, are resistant to moisture, chemicals and high temperatures, making them ideal for both construction and industrial installations. Their light weight makes installation easy and efficient.

Application in District Heating Systems and Other Industries

In district heating systems, PIR supports reduce heat loss, increase energy efficiency and extend the life of pipelines. They are also used in the plumbing, HVAC, refrigeration and chemical industries, where they protect systems and reduce the need for maintenance.

Application

Pipe supports in 60kg/m3 are essential components in industrial insulation where high compressive strength and load-bearing capacity are required.

Here are some of their primary uses:

Insulation:

Polyurethane pipe supports can contribute to thermal or acoustic insulation, depending on the material's specifications and application.

Corrosion protection:

Polyurethane pipe supports can act as a protective barrier against corrosion and further wear. They can prevent direct contact between pipes and other surfaces that could cause damage or degradation.

Flexibility in design:

Polyurethane pipe supports can be designed and manufactured in various sizes and shapes to meet specific project requirements, making them versatile and useful in many different types of systems and applications.

These properties make polyurethane supports a popular solution in many industries, including construction, energy, transportation and many other technical areas. The pipe supports are cast as standard in several dimensions and lengths, and we also offer special sizes.

Technical data sheet

Contact us for further information and product datasheet.

Technical specifications

| Material properties | Value | Standard |

|---|---|---|

| Density | > 60 kg/m3 | ISO 844:2021 |

| Fire classification | B3 | DIN 4102 |

| Compressive strength (lowest perpendicular to the foam direction) | > 300/500 kPa | ISO 845:2009 |

| E-Module | >7.5/14.5 MPa | ISO 1922:2018 |

| Stability | - 0.5 Vol % (100°C) | ISO 2796:2011 |

| Lambda | 0.0238-0.0255 W/m*k (10°C) | ASTM C518 |

| Closed cells | >92 % | ISO 4590:2016 |

| Application temperature | - 196/+148 °C |