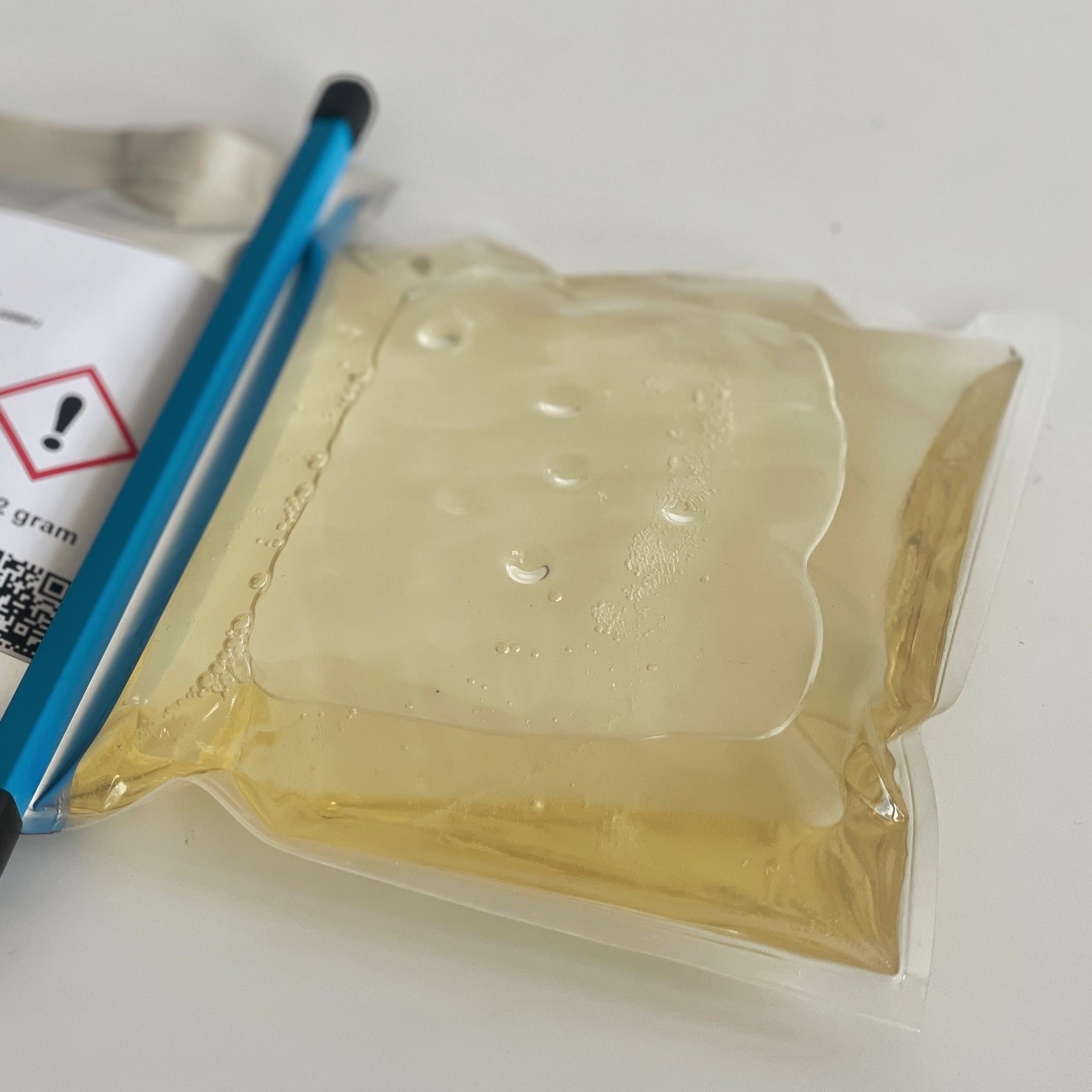

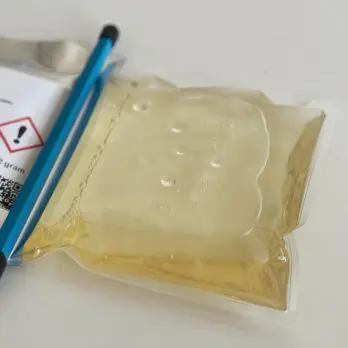

Mounting foam in bag

Mounting foam in bags is popular as the foaming is easy to handle. The bag contains both isocyanate and polyol. The separator between the two liquids is removed and the bag is shaken vigorously according to the instructions for use. During the mixing, a chemical process starts (a foaming). The foaming is carried out on site at the pipe joints and after welding.

Bag foam is an alternative to pipe bowls and is used, for example, between pipe and outer sleeve. Assembly foam in bags has been developed for assemblies of pre-insulated district heating pipes.

Dan-iso assembly foam has a shelf life after the production date of a full 20 months. Update regarding durability can be found under the specifications tab below.

Dan-iso assembly is produced in Denmark with EU raw materials. You will find the certificate of origin under the specification tab below.

You are always welcome to contact us for further information.

Application

Bag foam is an alternative to pipe bowls and is used, for example, between pipe and outer sleeve. Assembly foam in bags has been developed for assemblies of pre-insulated district heating pipes.

Technical data sheet

Contact us for product sheet.

Technical specifications

| Material properties | Value | Standard |

|---|---|---|

| Following... | Following... | Following... |