Mold for concrete pouring in construction

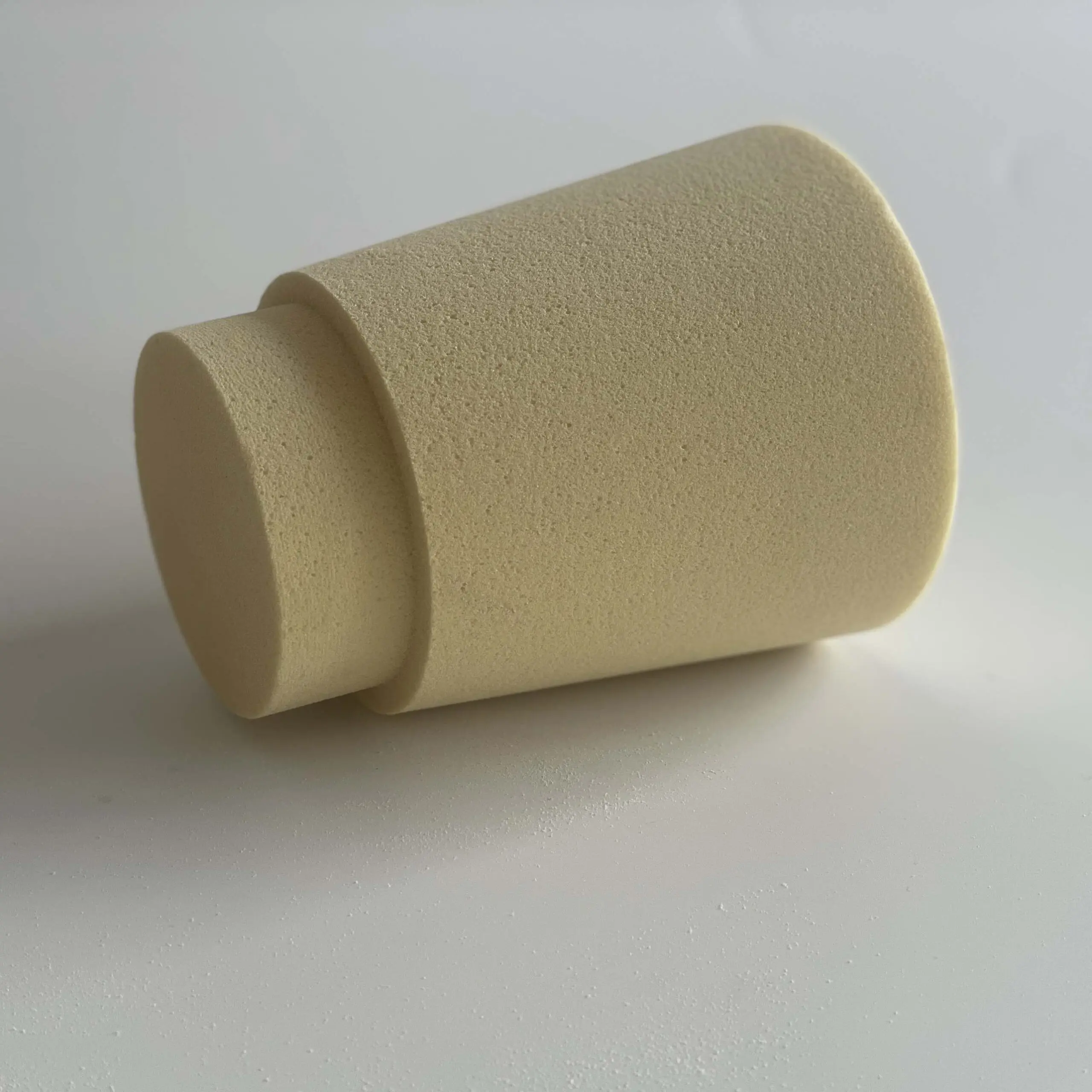

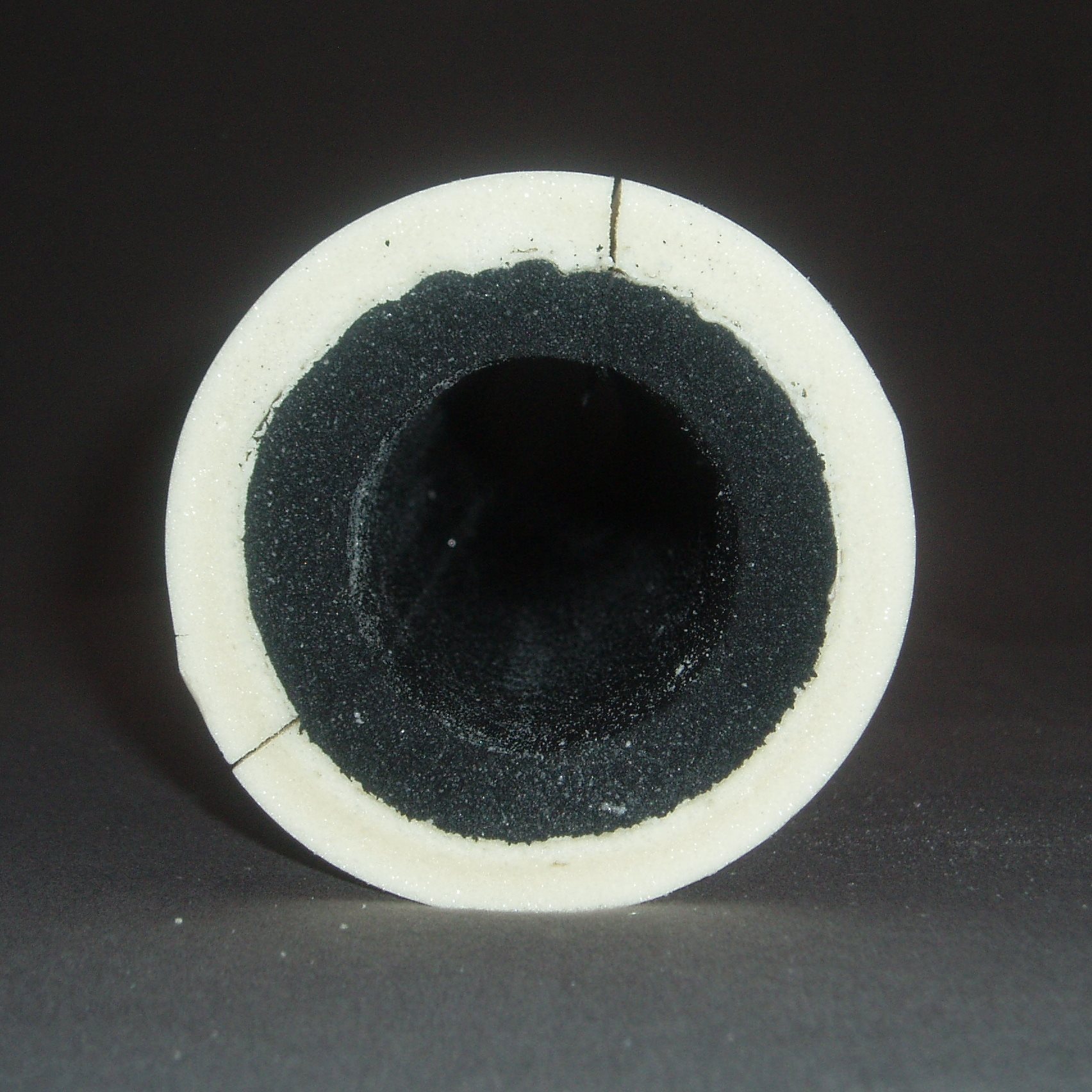

This product is a specially designed casting mold made of polyurethane (PUR) used to create precise lamp sockets in concrete elements. The mold here is CNC-milled in one piece, with different dimensions: a larger and a smaller cylinder shape. The surface of the mold is porous and textured, which ensures optimal adhesion and precision during the further casting process.

Features and benefits:

- Low weight: The lightweight PUR form makes handling and preparation for casting easier, reducing labor and time.

- Moisture-repellent: The material is resistant to water and moisture, preventing damage and ensuring long-term use.

- Dimensional stability: The form retains its structure and dimensions under load, ensuring precise and consistent concrete elements.

- Durability: PUR is durable and resistant to chemicals and extreme temperatures, making the mold long-lasting.

- Flexibility: The material can be adapted to different shapes and sizes, allowing for tailor-made solutions for specific construction projects.

This PUR casting mold is ideal for various casting projects where precision and durability are essential for creating reliable and functional elements such as integrated lamp sockets.

Application

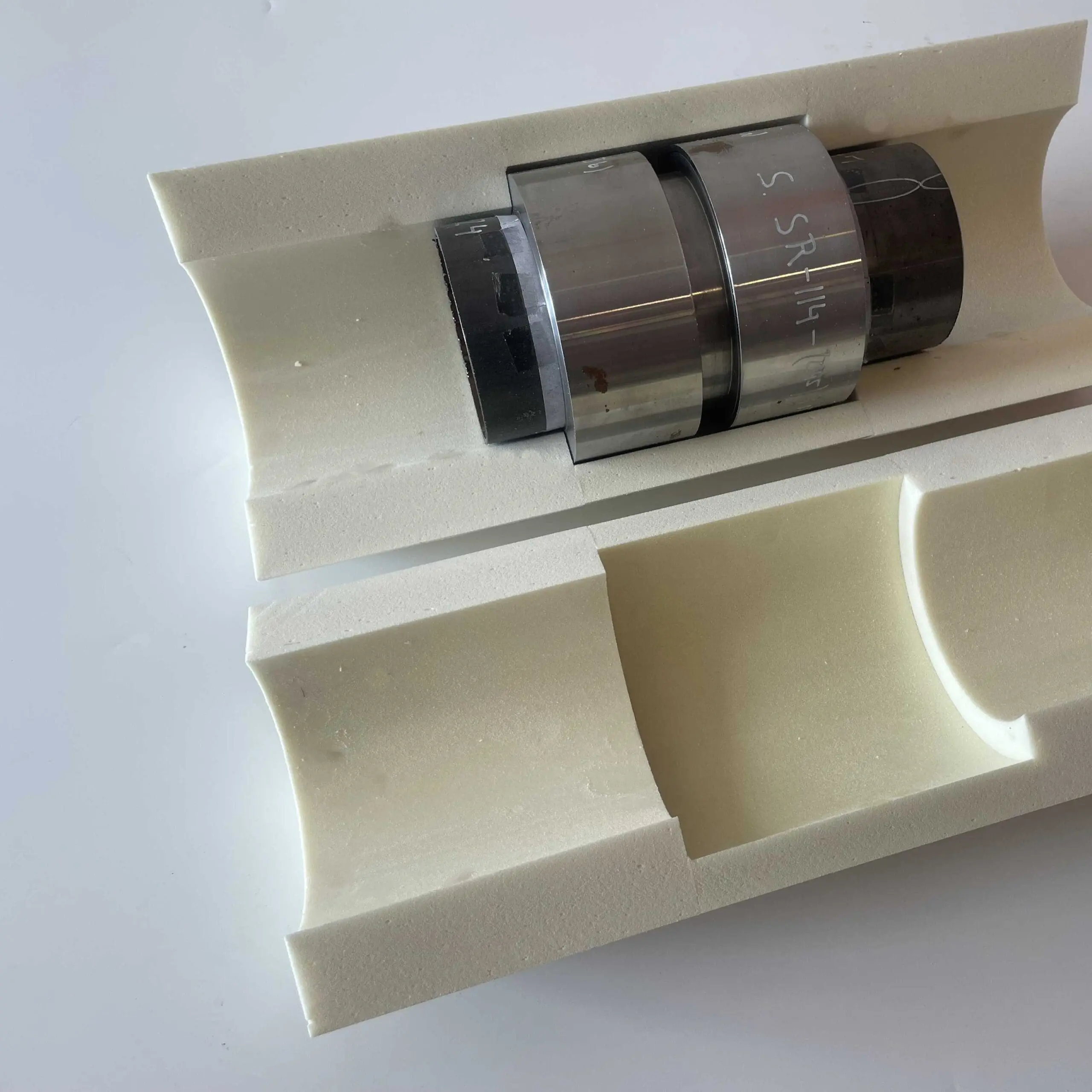

Use of specially milled and molded PUR parts

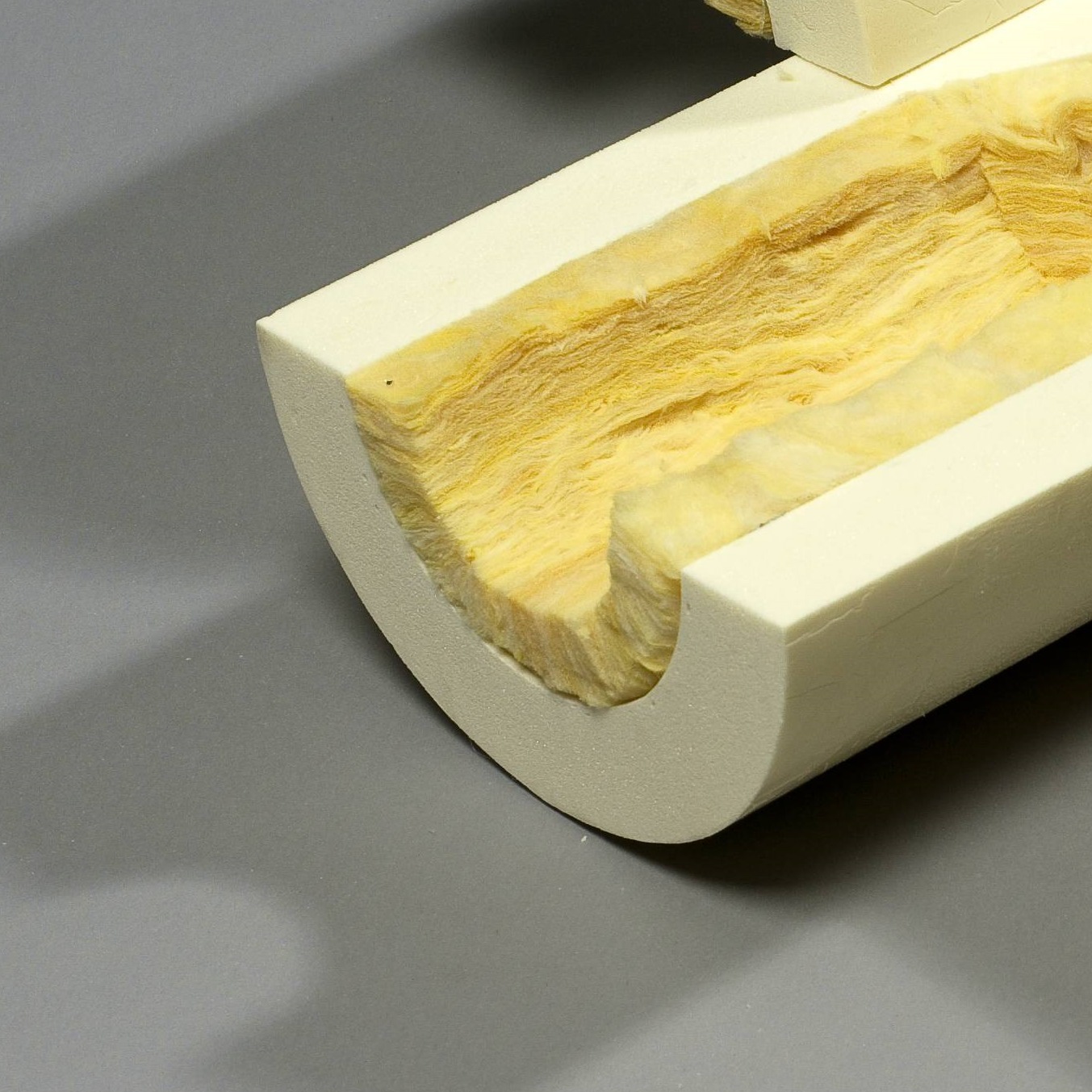

The polyurethane (PUR) casting mold is designed to create precise lamp sockets in concrete elements, making it ideal for use in construction projects. The mold is CNC milled in one piece (PUR 60 Dan-isoBLOCK block foam) and has two functional sections: a larger cylinder and a smaller, slightly protruding cylinder at one end. This construction ensures that the lamp socket is perfectly integrated into the concrete element during the casting process.

Molds milled or cast in polyurethane (PUR) are extremely versatile and can be used in a wide range of construction and industrial projects. These molds are ideal for projects where precision, durability and easy handling are essential.

Construction projects

In the construction industry, PUR molds can be used to create precise cutouts and embedments in various building materials. This includes projects such as installing electrical components, piping, and ventilation systems.

Industrial projects

In industry, PUR molds can be used to manufacture components that require high precision and dimensional stability. PUR's resistance to chemicals and extreme temperatures makes it an ideal material for use in demanding industrial environments.

Infrastructure projects

PUR forms can also be used in infrastructure projects, such as road and bridge construction, where precise embedments and outlets are required. The light weight and durability of PUR make it easy to handle and install, which can reduce labor and time.

Special projects

Due to the flexibility of PUR, the mold can be manufactured for customized solutions in special projects. This also includes use in art installations, prototypes and other creative projects where unique shapes and precision are needed.

Read more about Dan-iso CNC milling.

Technical data sheet

Contact us for product sheet.

Technical specifications

| Material properties | Value | Standard |

|---|---|---|

| Density | > 60 kg/m3 | ISO 844:2021 |

| Fire classification | B3 | DIN 4102 |

| Compressive strength (Lowest perpendicular to the foam direction) | > 300/500 kPa | ISO 845:2009 |

| E-module | > 7.5/14.5 MPa | ISO 1922:2018 |

| Stability | - 0.5 Vol % (100°C) | ISO 2796:2011 |

| Lambda (Lowest perpendicular to the foam direction) | 0.0238-0.0255 W/m*k (10°C) | ASTM C518 |

| Closed cells | > 92 % | ISO 4590:2016 |

| Application temperature | -196°C/ +148°C |