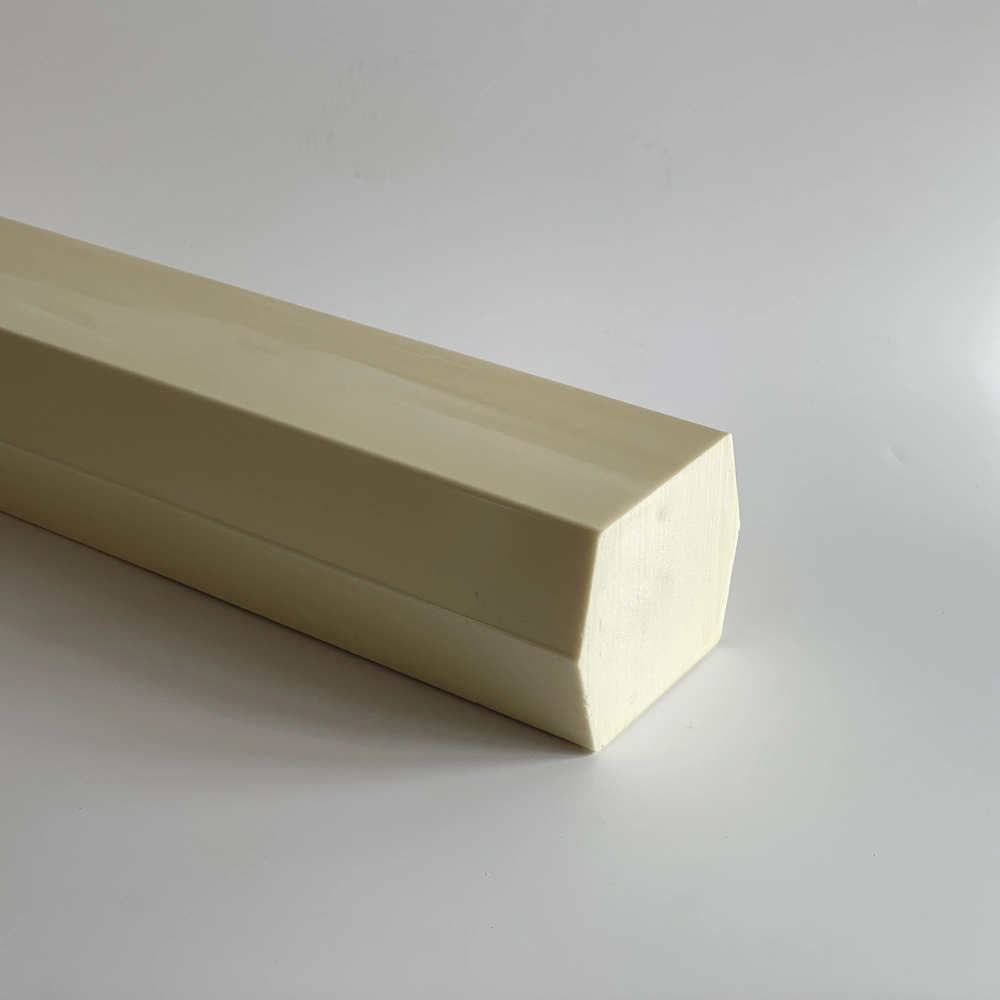

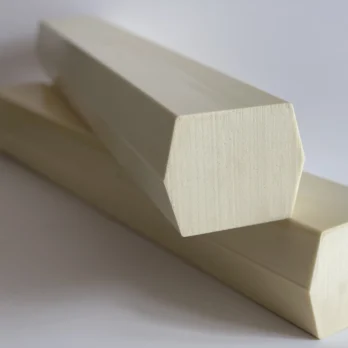

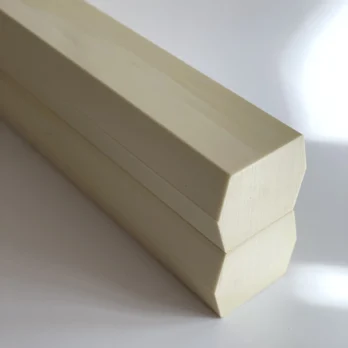

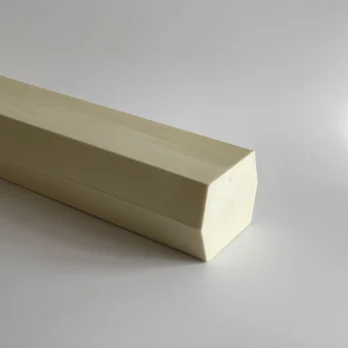

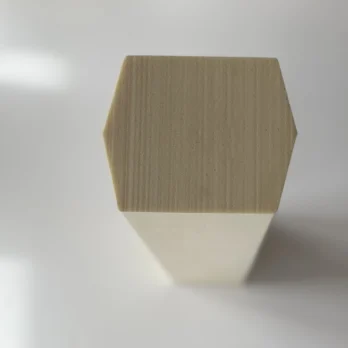

PUR beams for blocking and supporting piping

Dan-iso's PUR beams are designed for safe and flexible support of buried district heating pipes and pre-insulated pipe systems. They are used for temporary positioning before welding and as support during installation until permanent supports are installed. The PUR material deforms in a controlled manner - that is, the beam gradually adapts to the load without losing its function. This makes it possible to leave the beams under cover, unlike wooden battens, which must be removed.

The beams are made of hard PUR with high compressive strength, low weight and high chemical resistance. The material is approved according to EN 253 and has the same mechanical properties as the insulation on district heating pipes, ensuring optimal compatibility. The PUR beams can also be used for storing steel pipes and other items where stable and gentle support is desired.

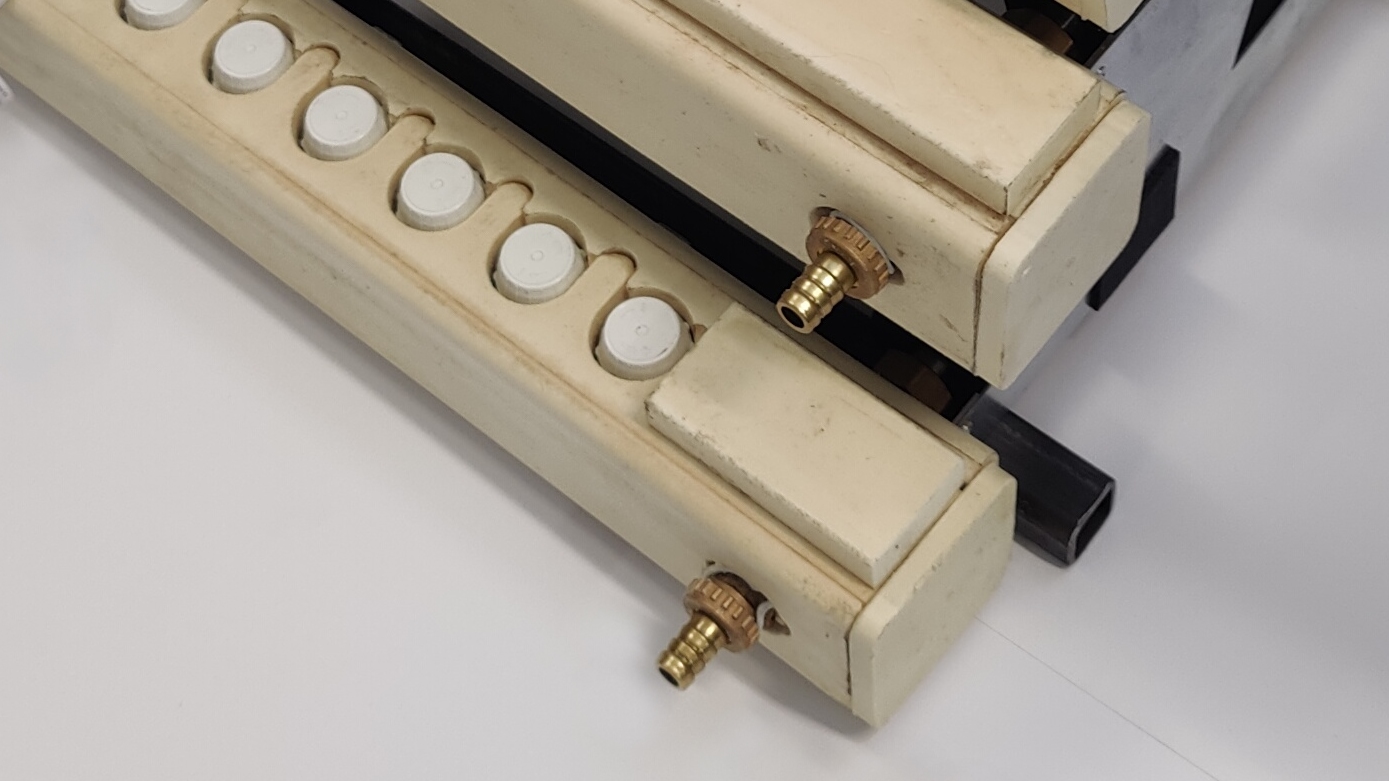

Special solutions in PUR and PIR

Dan-iso offers customized solutions in both PUR and PIR foam. We develop and deliver special items in desired dimensions and geometries – adapted to specific load requirements and applications within industry, construction and technical installations. Contact us for advice and development of solutions that match your needs.

Application

Application

PUR beams from Dan-iso are primarily used for blocking and temporary support of buried district heating pipes and pre-insulated pipe systems during installation. They ensure correct positioning before welding and can remain under the pipes after covering, as the PUR material deforms in a controlled manner and adapts to the load without losing its function. The beams are also suitable for storing steel pipes and other items where stable and gentle support is required. In situations without special requirements for load-bearing capacity, the PUR beams can replace traditional wooden battens. In addition, the beams can be adapted to uneven terrain by turning them upside down, which provides extra height and flexibility.

Technical data sheet

Contact us for product sheet.

Technical specifications

| Material properties | Value | Standard |

|---|---|---|

| Density | > 60 kg/m3 | ISO 844 |

| Compressive strength (Lowest perpendicular to the foam direction) | > 0.30 MPa | ISO 845 |

| E-module | > 10 MPa | ISO 844 |

| Stability | - 1 Vol % (100°C) | ISO 2796 |

| Lambda (Lowest perpendicular to the foam direction) | < 0.026 W/m*k (10°C) | ASTM C518 |

| Closed cells | > 92 % | ISO 4590 |

| Water absorption | < 4.4 Vol % | EN 253 |