Dan-isoKIT – complete insulation kit for pre-insulated joints

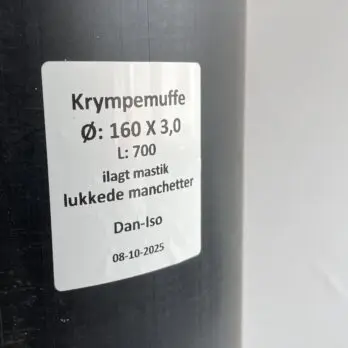

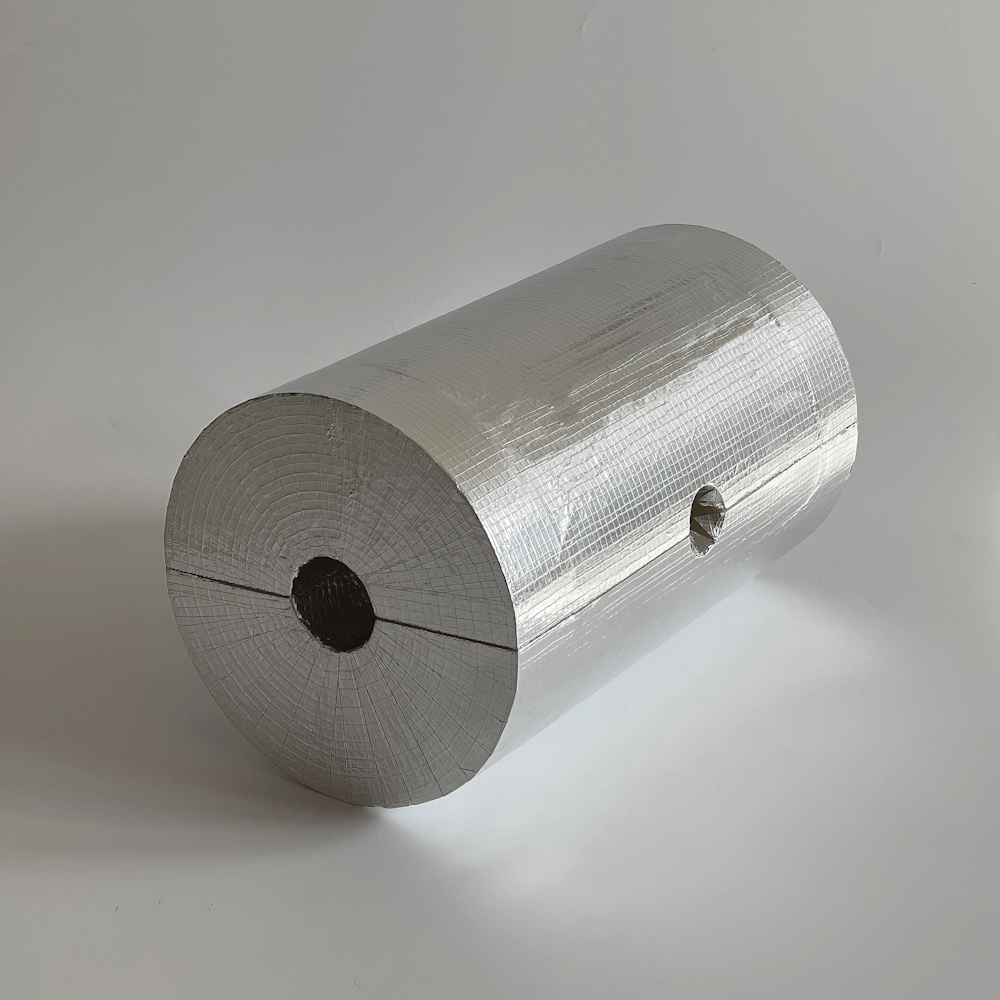

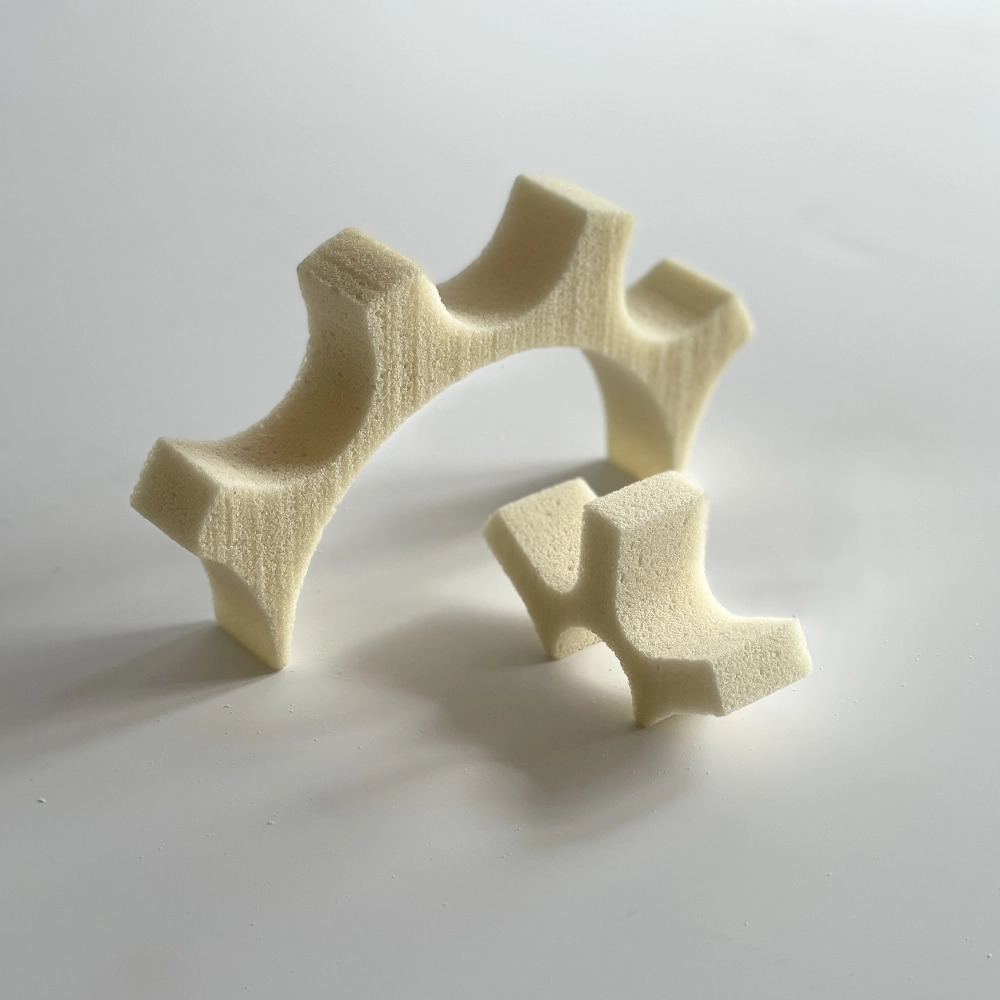

Dan-isoKIT is a complete insulation kit developed for efficient and reliable insulation of joints in connection with pre-insulated pipe installations. The kit combines PUR pipe shells, PE sleeve with mastic sealant and tight-fitting sleeves, which together ensure double high insulation performance, quick installation and long service life.

The solution is designed for district heating, process plants and technical installations where energy efficiency and protection against moisture penetration are crucial. With Dan-isoKIT, the installer gets a complete, quality-assured system – produced and tested according to Dan-iso's high standards.

Application

KIT #1) Kit with pipe bowl, PE sleeve with mastic and sleeves

Prepare the pipe: Make sure the surface is clean and dry before assembly.

Mount the PUR pipe shell around the pipe and secure with tape or a locking system.

Place the PE sleeve over the joint and apply the supplied mastic to ensure tightness.

Finish with cuffs at both ends – they protect against moisture and mechanical impact.

Check the assembly for proper fit and tightness.

Dan-isoKIT is compatible with most pipe dimensions and can be adapted to both new and existing systems.

KIT #2) Kit with pipe bowl with shroud and ….

Prepare the pipe: Make sure the surface is clean and dry before assembly.

Mount the PUR pipe shell around the pipe and secure with tape or a locking system.

Place the PE sleeve over the joint and apply the supplied mastic to ensure tightness.

Finish with cuffs at both ends – they protect against moisture and mechanical impact.

Check the assembly for proper fit and tightness.

KIT #3) Kit with pipe bowl with shroud and ….

Prepare the pipe: Make sure the surface is clean and dry before assembly.

Mount the PUR pipe shell around the pipe and secure with tape or a locking system.

Place the PE sleeve over the joint and apply the supplied mastic to ensure tightness.

Finish with cuffs at both ends – they protect against moisture and mechanical impact.

Check the assembly for proper fit and tightness.

Technical data sheet

Contact us for more information about the kit.

Technical specifications

| Material properties | Value | Standard |

|---|---|---|

| Density | > 68 kg/m³ (± 8 kg/m³) | ISO 845 (/DIN 53420-78) |

| Closed cells | ≥ 88 % | ISO 4590 |

| Cell size | < 0.5 mm | EN253 5.3.2.1 |

| Water absorption during boiling | Mean value 4.4 % Vol | EN253 5.3.5 |

| Compressive strength, radial | ≥ 0.40 Mpa | ISO 844 |

| E-module, radial | ≥ 9.5Mpa | ISO 844 |

| Dimensional stability | ||

| - 30 C° | 48h: 0.0 % vol | |

| + 100°C | 48h: -1.0 % vol | ISO 2796 (/DIN 53431-77) |

| + 150°C | 48h: -1.4 % vol | |

| Thermal insulation value (thermal conductivity) freshly foamed | ||

| λ10 | 0.0238 W/m*K | |

| λ20 | 0.0247 W/m*K | ISO 8301 / ASTM C518 |

| λ50 | 0.0284 W/m*K |