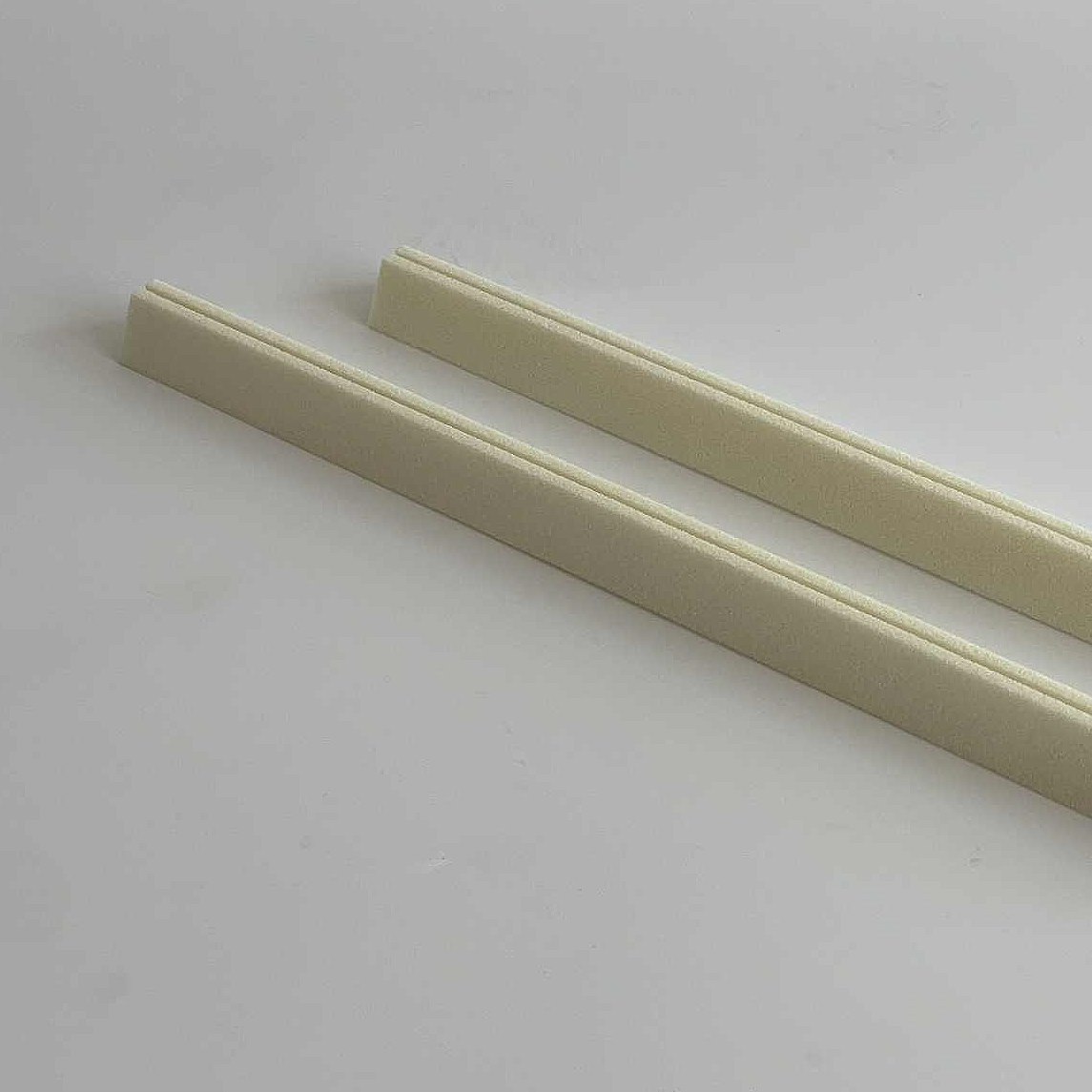

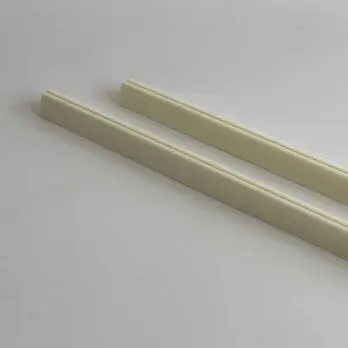

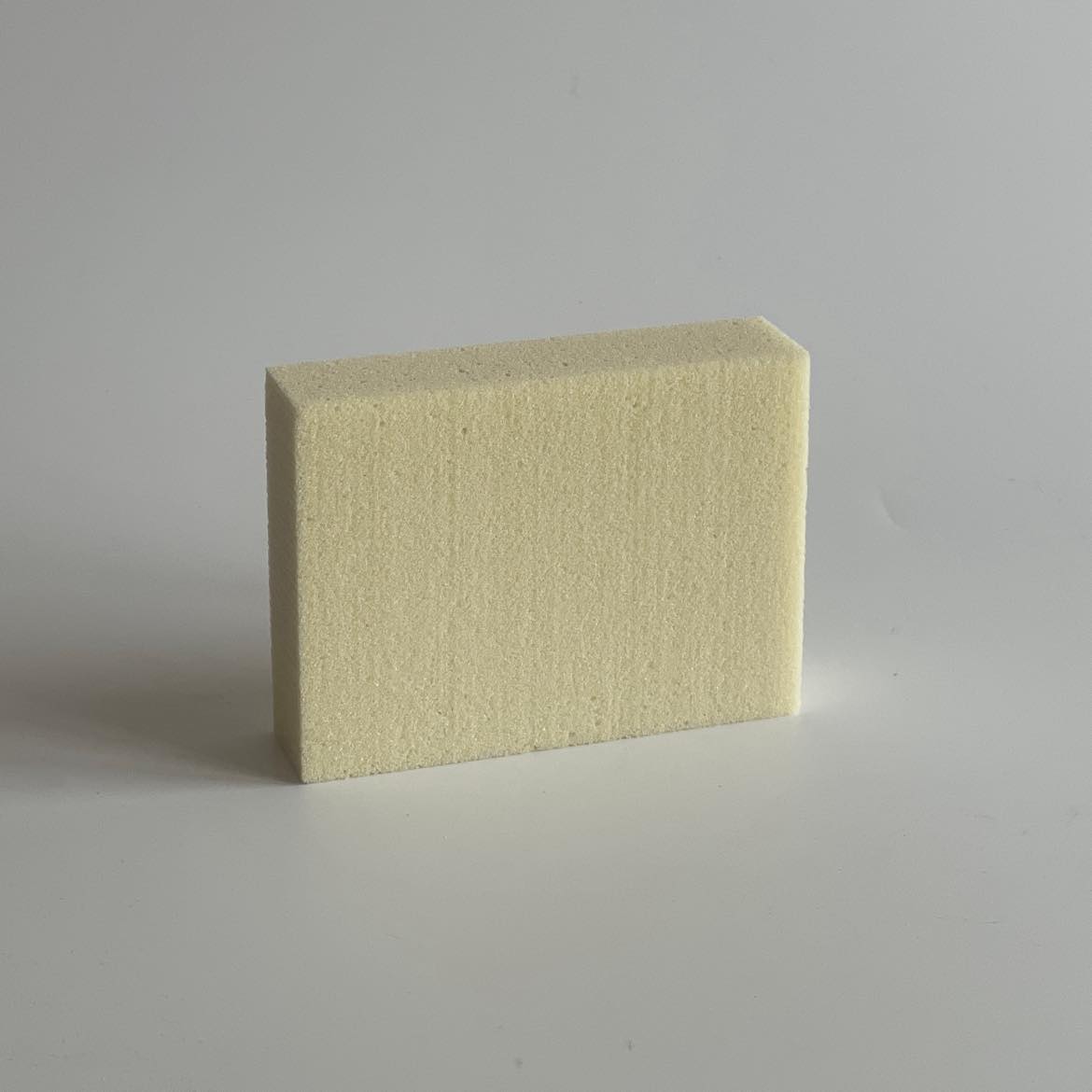

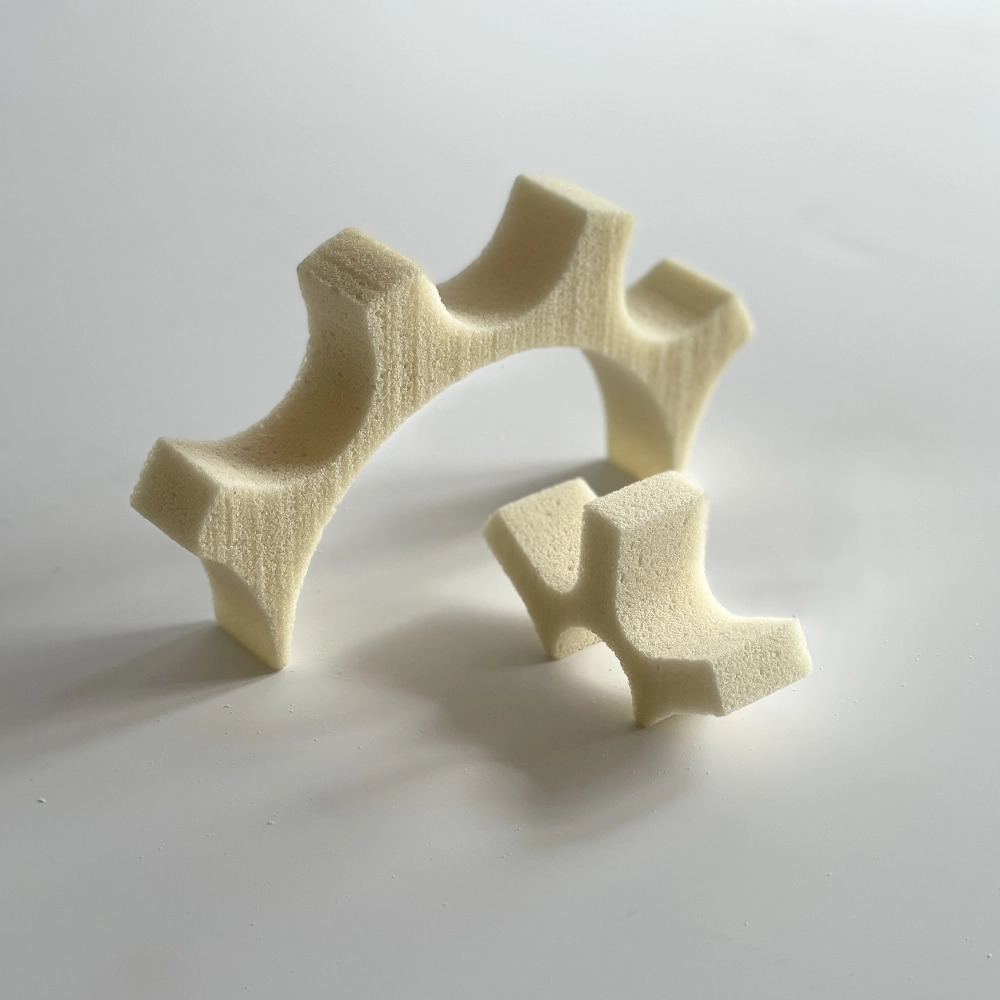

Our alarm wire holders are designed for use in polyurethane foaming and ensure stable attachment of alarm wires during the foaming process. They are made of rigid polyurethane, which provides high strength, flexibility and resistance to moisture and temperature fluctuations.

Advantages:

- Compatible with PU foam: Holds the shape under foam pressure and ensures correct placement of the alarm wire.

- Long life: Resistant to chemicals, moisture and mechanical stress.

- Easy assembly: Designed for quick and secure fastening in pipe structures.

With Dan-iso's alarm wire holders you get a professional solution that combines functionality, durability and energy efficiency.

Application

Application

Polyurethane alarm wire holders are designed to meet the high demands of industrial insulation projects. They are particularly suitable for use in industrial pipe installationswhere a stable and secure attachment of alarm wires is required during the insulation process. These holders are designed to withstand the pressure and temperature fluctuations that occur when polyurethane foam is applied around the pipes.

IN district heating and cooling systems Correct placement of the alarm wire plays a crucial role in the operational reliability of the system. Alarm wire holders ensure that the wire remains in the desired position, even when the insulation material expands during curing. This reduces the risk of errors and ensures that the monitoring system functions optimally throughout the entire life of the system.

By insulation projects with polyurethane The choice of material is essential. Polyurethane holders prevent thermal bridges, contributing to an energy-efficient solution. In addition, they are resistant to moisture, chemicals and mechanical stress, making them ideal for demanding environments.

Technical data sheet

Contact us for product sheet.

Technical specifications

| Material properties | Value | Standard |

|---|---|---|

| Density | > 60 kg/m3 | ISO 844 |

| Fire classification | B3 | DIN 4102 |

| Compressive strength (Lowest perpendicular to the foam direction) | > 300/500 kPa | ISO 845:2009 |

| E-module | > 7.5/14.5 MPa | ISO 1922:2018 |

| Stability | - 0.5 Vol % (100°C) | ISO 2796:2011 |

| Lambda (Lowest perpendicular to the foam direction) | < 0.0238-0.0255 W/m*k (10°C) | ASTM C518 |

| Closed cells | > 92 % | ISO 4590:2016 |

| Application temperature | - 196/+148 °C | - |