Dan-iso supports the green transition. Power-to-X (PtX) converts green electricity into hydrogen, e-methanol and other synthetic fuels – and our polyurethane insulation ensures energy-efficient and reliable systems.

- Very high insulating capacity

- High strength/weight ratio

- Torsional stability

- Temperature stability

- Chemical resistance

Energy-efficient PUR pipe insulation for PtX systems

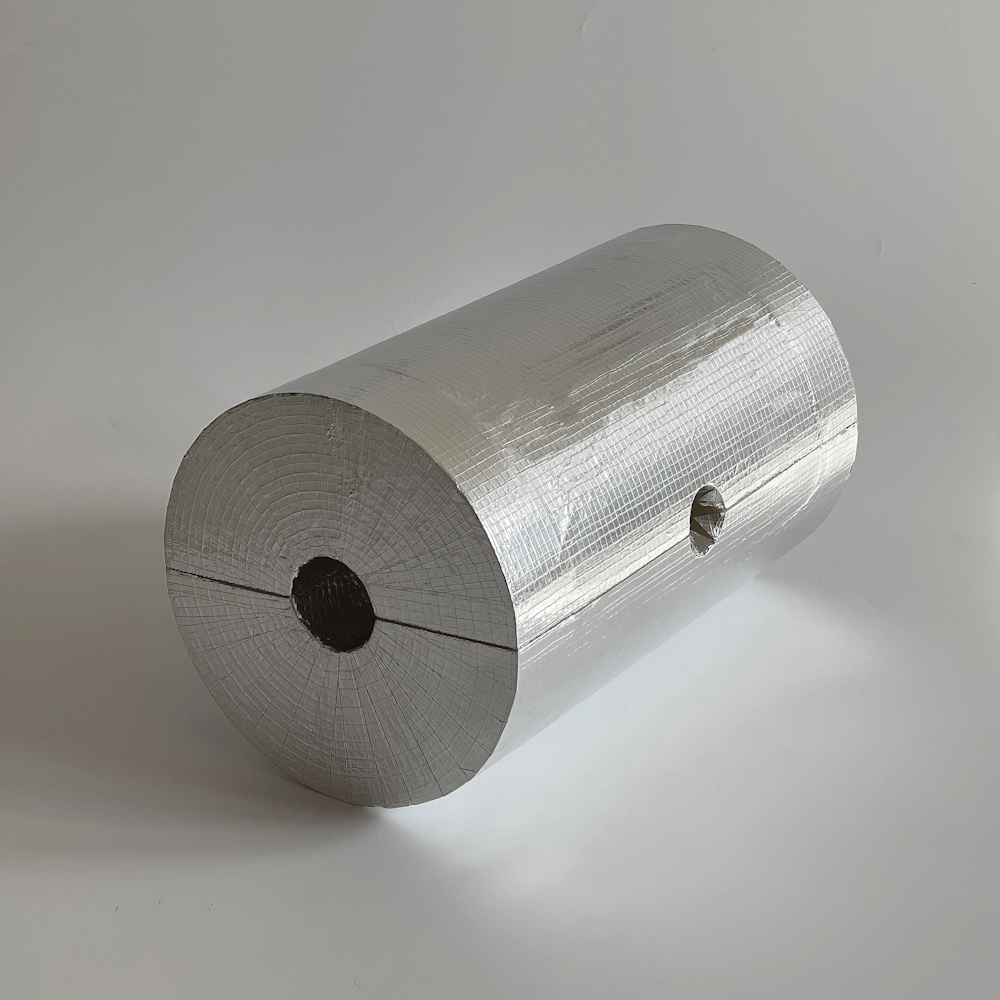

PUR pipe insulation for electrolysis plants and hydrogen distribution has a low thermal conductivity, which minimizes heat loss and increases overall energy efficiency. Even small heat losses can have a major impact on the plant's operation and economy. Dan-iso's solutions contribute to stable process conditions, reduced energy consumption and less need for readjustment of temperature control systems, ensuring that PtX plants can operate more efficiently over time.

PtX plants are often exposed to moisture, chemicals and large temperature fluctuations. Dan-iso's PUR insulation is resistant to condensation, aggressive media and temperature variations, while maintaining its dimensional stability and flexibility. This makes it possible to insulate complex piping, specially designed process installations and tanks without compromising operational reliability or performance.

Power-to-X: Technical insulation solutions for the energy plants of the future

Technical insulation solutions for future energy plants

Power-to-X (PtX) is one of the cornerstones of the green transition. The technology converts electricity from renewable energy sources into hydrogen, e-methanol and other synthetic fuels, making it a critical component in the development of sustainable energy systems. PtX plants place special demands on materials and installations, where energy efficiency, temperature control and long service life are paramount. Here, Dan-iso offers tailor-made polyurethane insulation solutions that ensure optimal operational reliability and minimal energy waste.

PUR insulation for PtX: Why is it important?

High demands on energy efficiency

We know that PtX systems place high demands on energy efficiency, temperature control and long-lasting materials. With our solutions, we offer:

- Low thermal conductivity – minimizes energy loss

- Robustness – against moisture, chemicals and temperature fluctuations

- Form stability and flexibility – for complex geometries, piping and process plants

The result is safe operation, low heat loss and longer service life – for electrolysis plants, hydrogen distribution and e-fuel production.

Cooperation

We work closely with insulators, contractors, engineering firms and consultants who design PtX plants. Our technical team delivers:

- Advice on materials and product selection

- Tailor-made insulation solutions in PUR and PIR

Want to know more? Contact us for technical advice, product data or a non-binding meeting.

Let us assist you

Do you have questions or need help? Please do not hesitate to contact us - we look forward to hearing from you.