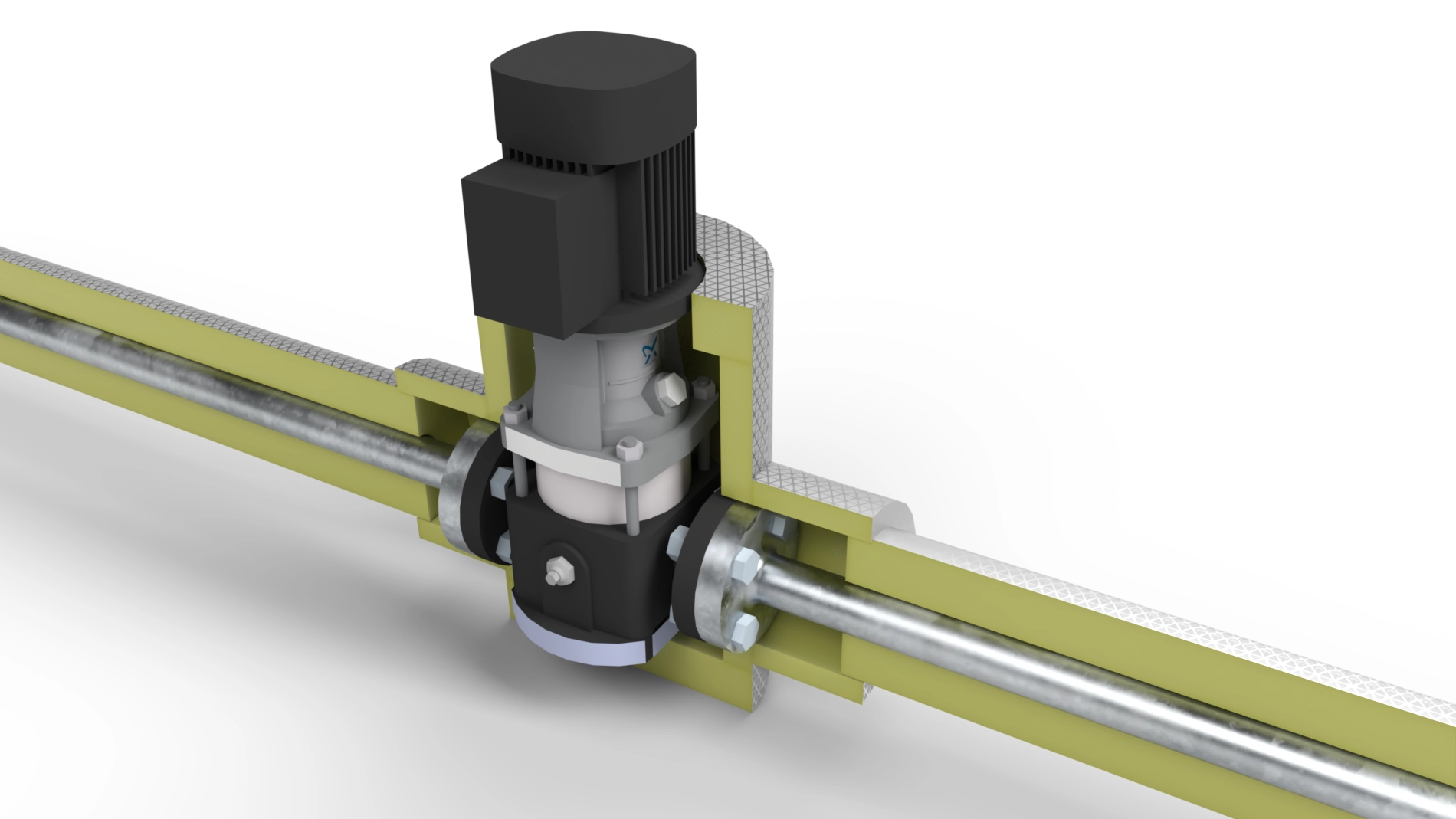

As the industry increasingly focuses on energy efficiency and sustainable solutions, it is no longer enough to simply insulate pipes. One often overlooked but highly effective method to reduce energy consumption and improve operational efficiency is insulating industrial pumps – especially the indispensable centrifugal pumps.

Heat Loss = Money Lost

Centrifugal pumps are a cornerstone of many industrial systems. They are used to efficiently transport large volumes of fluids under pressure and are found in everything from water supply and wastewater treatment to chemical production and district heating. While their mechanical operation is efficient, a hidden energy drain lies in their design: the large surface area.

When the fluid in the system is hot – for example, in district heating or process plants – the pump surface acts as an efficient heat emitter to the surroundings. This results in valuable energy being lost, and the system must use extra resources to compensate for this heat loss.

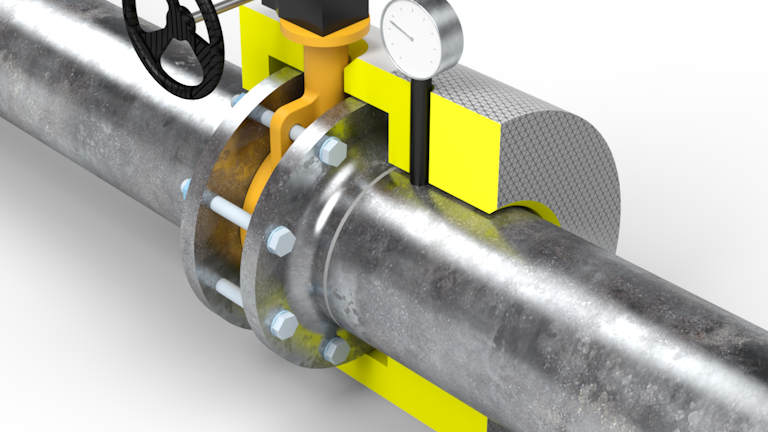

PUR insulation: A simple solution with significant impact

By insulating the pumps, heat loss can be significantly reduced. Effective insulation retains the energy of the fluid and prevents it from escaping into the surrounding environment. This not only leads to lower energy costs but also improves the operational efficiency and stability of the entire system.

Industry analyses show that proper pump insulation can reduce energy consumption by up to 20-30%, depending on the application and pump size. This translates directly into cost savings, especially in energy-intensive industries.

More than just energy savings

PUR (polyurethane) pipe insulation also offers mechanical benefits. It protects pump components from extreme temperatures and reduces the risk of overheating. This extends the lifespan of the equipment and reduces the need for maintenance and replacement of parts. In other words, technical pipe insulation is not just an energy-saving solution – it's also an investment in operational reliability.

Insulating the entire system – not just the pipes

In many installations, the focus is on insulating the pipes – and for good reason. Pipes represent a significant portion of the surface area where heat can be lost. However, in the rush to optimize pipe insulation, pumps and flanges are often overlooked. This can be a costly mistake.

At Dan-iso A/S, we specialize in PUR and PIR insulation solutions that cover the entire system – pipes, pumps, and flanges. Our experience shows that it’s only when all components are properly insulated that the full savings potential is realized.

Centrifugal pumps – A vital component of energy-saving systems

Centrifugal pumps are known for their reliability and ability to handle large volumes of liquid under pressure. However, their design – with a large surface area and constant operation – makes them particularly vulnerable to energy loss. Insulation is not an option here; it’s a necessity for operating a modern, energy-efficient system.

Conclusion: Don’t overlook the pumps

In the pursuit of energy savings and sustainable solutions, it’s important to consider the whole picture. Pipe insulation is crucial, but without a corresponding focus on pumps and flanges, the full benefits won’t be realized.

We work to ensure that the entire thermal system operates optimally. With custom-made PUR and PIR pipe insulation solutions for centrifugal pumps, we help companies save energy, protect their equipment, and support the green transition.

Read other related news

Our employees are the foundation

Strong results are created by people who thrive – both professionally and personally. Therefore, employee well-being and proper working conditions are a…

Unimaginable special solutions and possibilities in PUR and PIR

The Cimbrer bull stands at the entrance to Friis Shoppingcenter Streetfood in Aalborg. We are thrilled to have contributed to 'shaping'…

Dan-iso invests in solar panels – A step towards a greener future

2024 was concluded with the installation of solar panels at Dan-iso A/S, and we are happy to be able to take this important step towards a greener future.…

Effective insulation of external heat pumps

When it comes to pipe insulation of outdoor heat pumps, precise temperature conditions and material properties play a crucial role in…

The core of our forging department in Havbro

Our forging department's commitment to quality is not just about producing strong and reliable molds – it also helps reduce material…

Energy optimization in the district heating sector

In a world where energy optimization and sustainable solutions have become our shared responsibility, insulation plays a major role. When we talk about…