Sustainability in the green transition

In the green transition, there has been an increased focus on the importance of insulating technical installations. It costs energy to heat up liquids and correspondingly to cool them down. Effective insulation of the piping is therefore an important ingredient in the recipe for more sustainable production and operation.

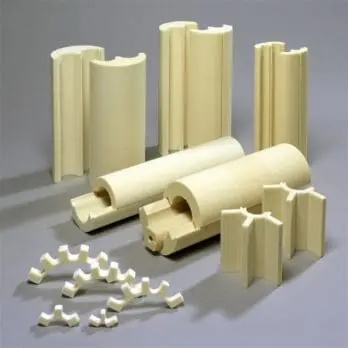

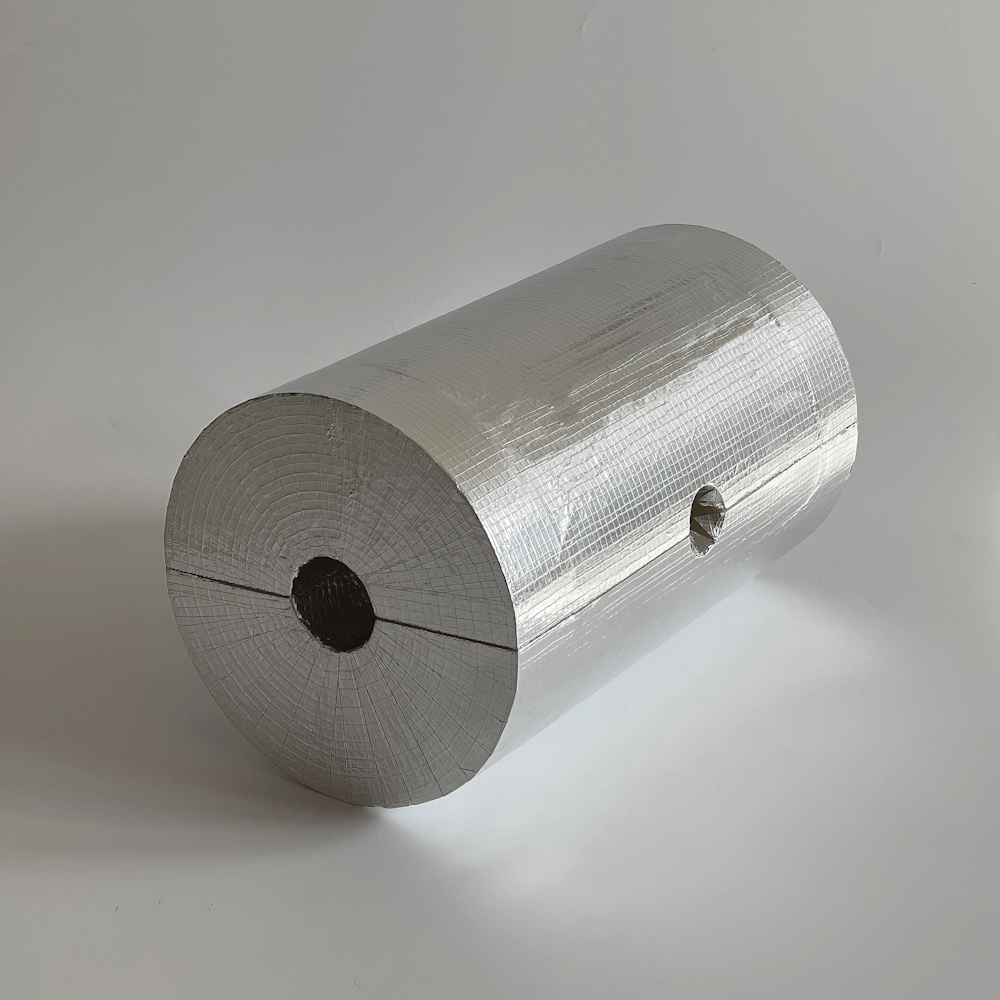

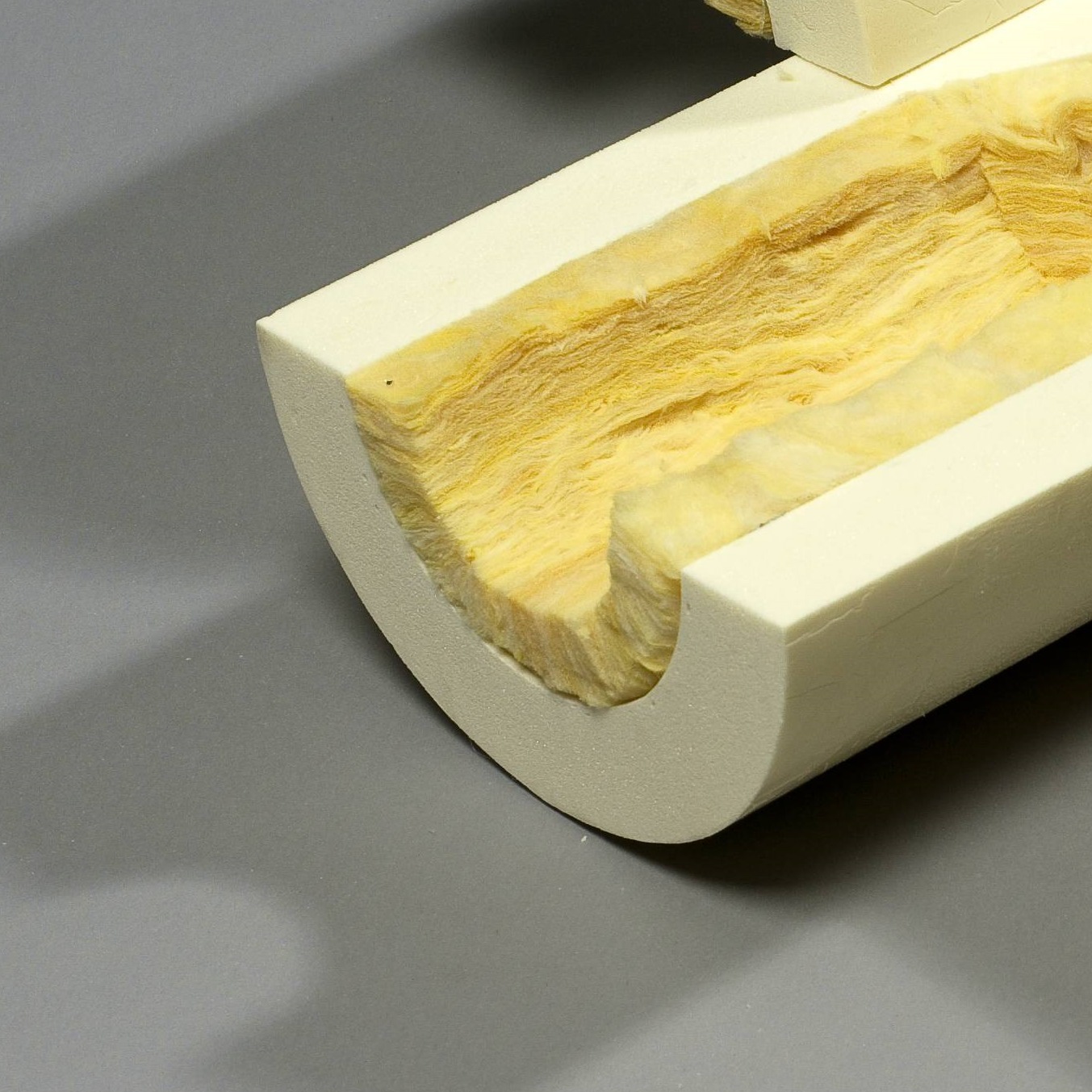

Pipe insulation in cell foam in the form of PUR and PIR has a formidable insulating capacity and a long life, as it does not absorb moisture or collapse. When using PUR and PIR insulation, the loss of heat and cold is reduced far more effectively than with classic insulation types, which saves the world from unnecessary CO2 emissions.

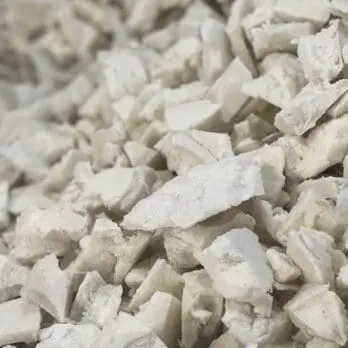

However, the production of PUR insulation generates a lot of waste. Waste that cannot be immediately recycled and is therefore disposed of. The disposal of PUR can emit up to 4 tonnes of CO2 for every tonne of PUR waste and is thus a significant factor in the CO2 accounts.

45 % recycled regenerates

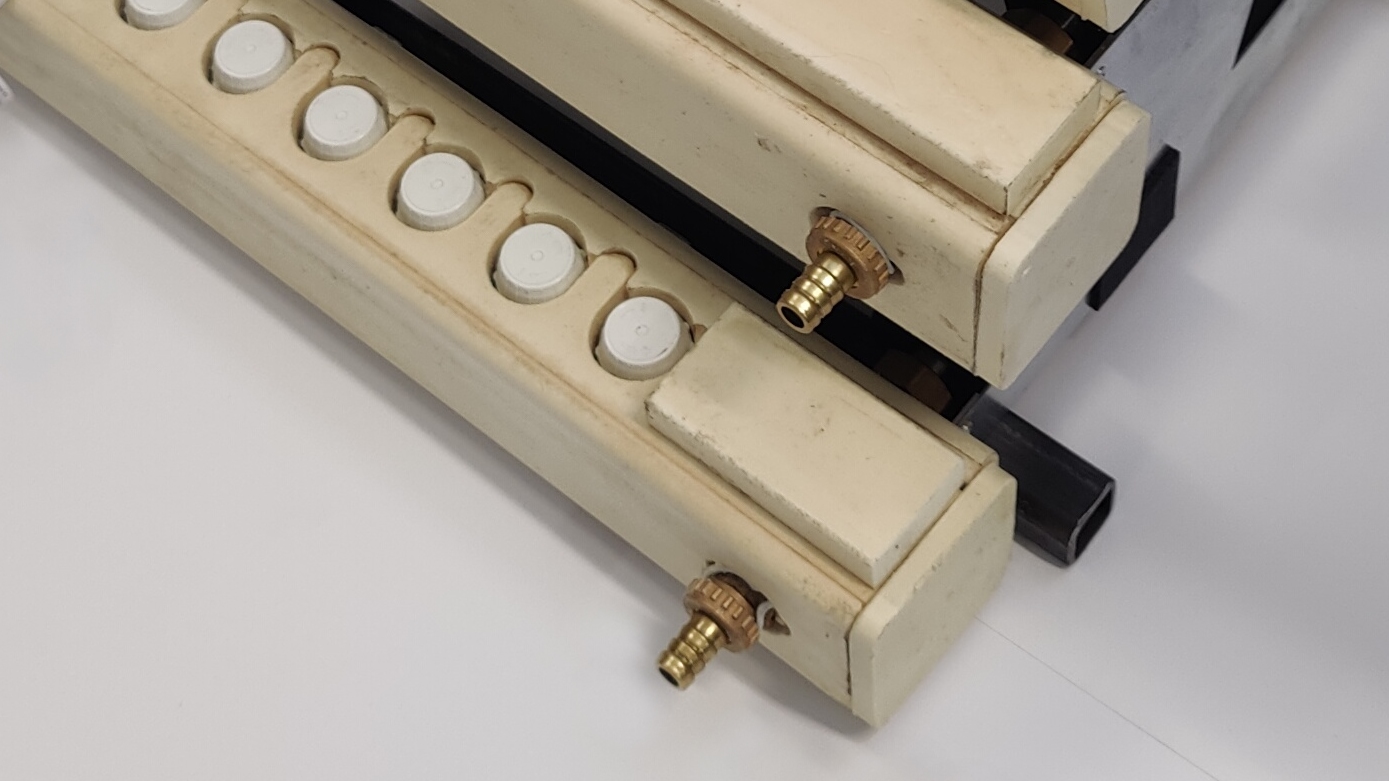

We have created unique results with the recovery of the surplus material from production and can now cast insulation materials with 45% regenerated. Regenerate in the form of hardened PUR, where we recover the production waste and thereby contribute to a more sustainable production.

In the past, it has been associated with very large technical challenges to recover rigid polyurethane foam in a way where the material's most important technical properties are preserved. Industrial recovery of PUR has been minimal and success stories from the industry have been about recycling 2-10 % of the production waste.

Our success with upcycling is the result of an intensive development process, where reducing residual products and giving new life to waste has been the primary objective. In the process, we have worked with 2 methods, which have given good results. The one technology is now ready to be implemented in production and deliver greener insulation. With the latest results, it has thus been possible to cast products with a high degree of recycling, which at the same time have fully equivalent insulation value and material properties as ordinary molded PUR.

Recycled insulation that saves space

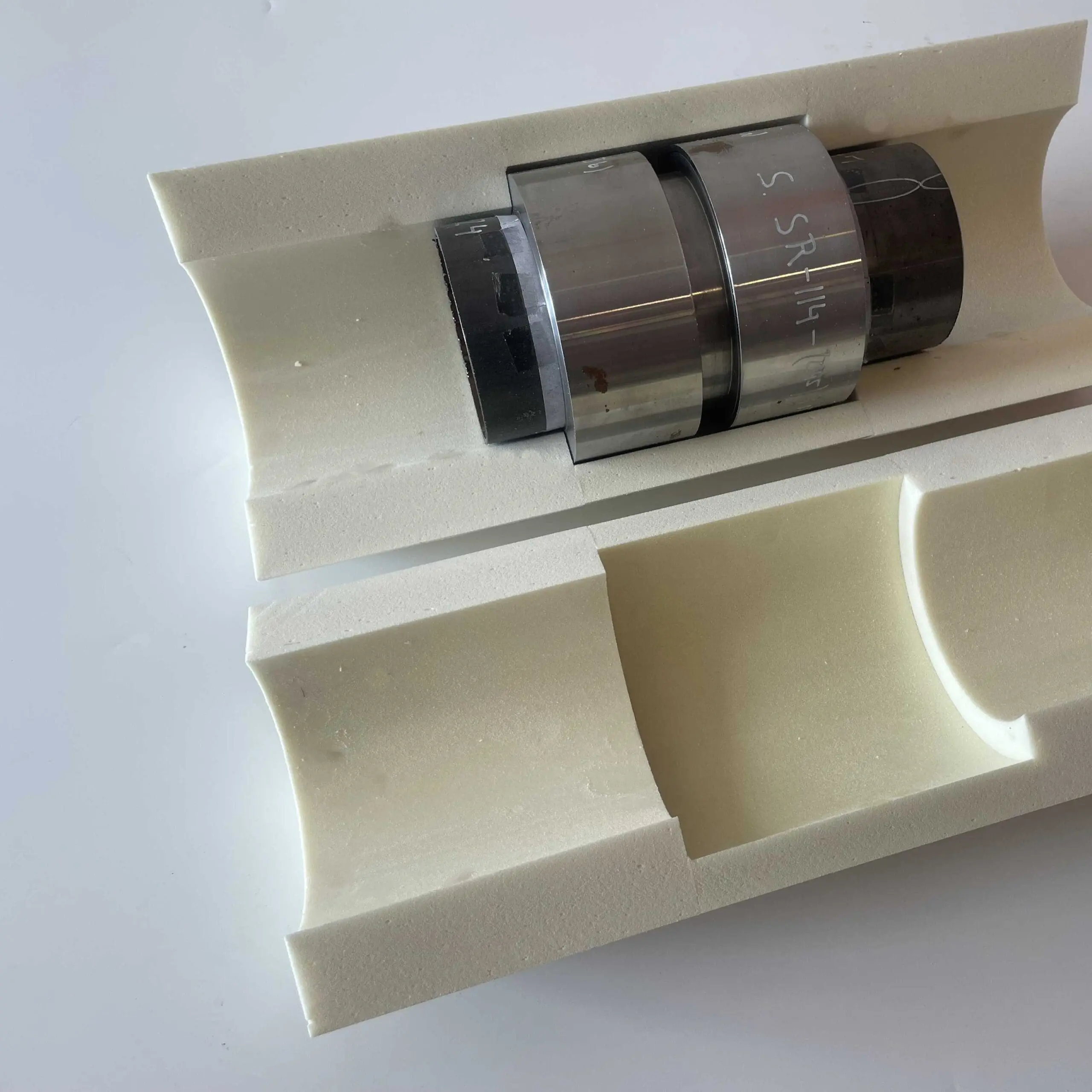

By recovering excess PUR, we can reduce our waste volume considerably and protect the environment from waste disposal. The new production of greener insulation also opens up new markets, as insulation with regenerated materials may not be sold to the district heating industry, as the standard for underground pipe systems does not allow recycled materials. This benefits the plumbing industry, as insulation with regenerated material can be used in places that today are either not insulated due to lack of space or where more traditional insulation materials are used. PUR insulation with regenerated material is ideal for insulating technical installations, where the highly efficient insulation takes up far less space than traditional forms of insulation. The insulation from Dan-iso can thus help meet the requirements for insulation against heat loss and condensation in new buildings and renovations.

Technical data sheet

Contact us for product sheet.

Technical specifications

| Material properties | Value | Standard |

|---|---|---|

| Following... | Following... | Following... |