Effective pipe insulation and sustainability in the oil and offshore industry with PUR and PIR.

- Energy-saving insulation

- Sustainability and circular economy

- Form-stable support and blockwork

- Collaboration and innovation

In the oil and offshore industry, energy optimization and sustainability are decisive factors. They meet today's demands for efficient resource utilization.

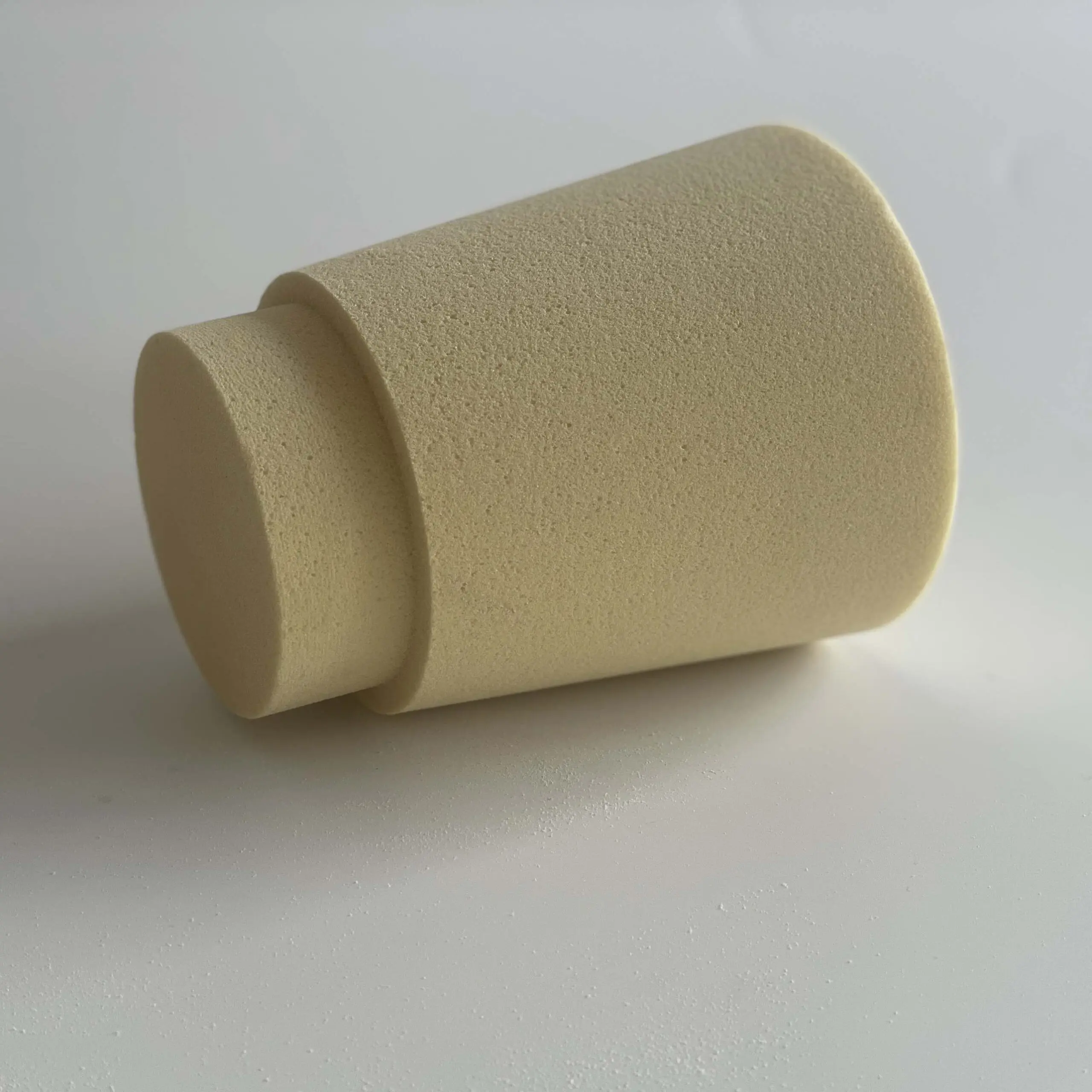

Polyurethane (PUR) and polyisocyanurate (PIR) are materials that play a central role. They improve both insulation and structural support in this sector.

Energy-saving insulation

Insulation properties of PUR and PIR in the Offshore industry

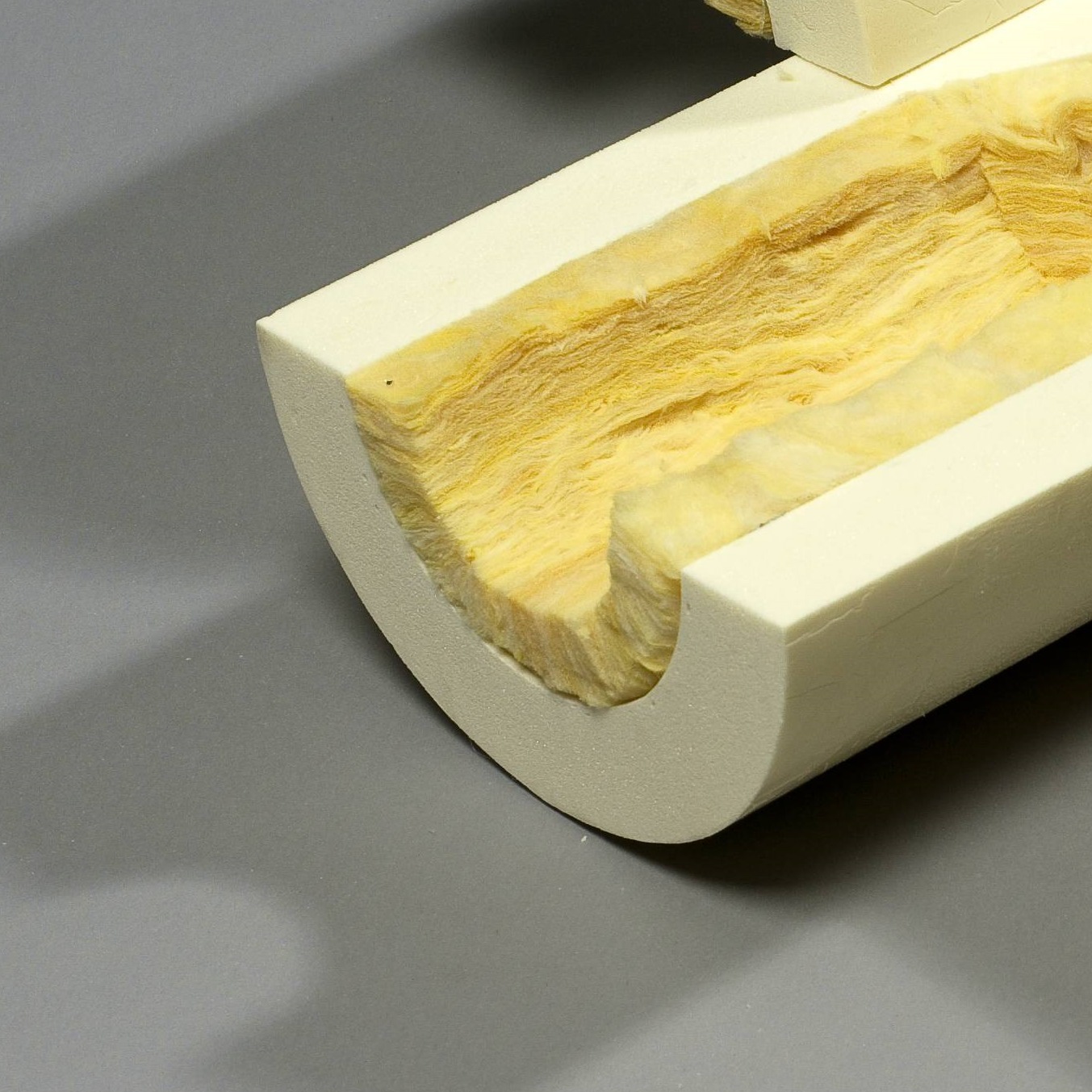

PUR and PIR offer excellent insulation properties. They help minimize energy loss in offshore facilities and installation environments.

The high insulating ability with low thickness optimizes the space. Efficiency is maintained without compromising thickness. This is particularly important in challenging environments where temperature control is critical to operational reliability.

Both PUR and PIR contribute to a more sustainable practice in the oil and offshore industry. By reducing energy consumption, the overall environmental impact is reduced.

The possibilities for recycling materials support a circular economy. This provides greater efficiency and takes the environment into account.

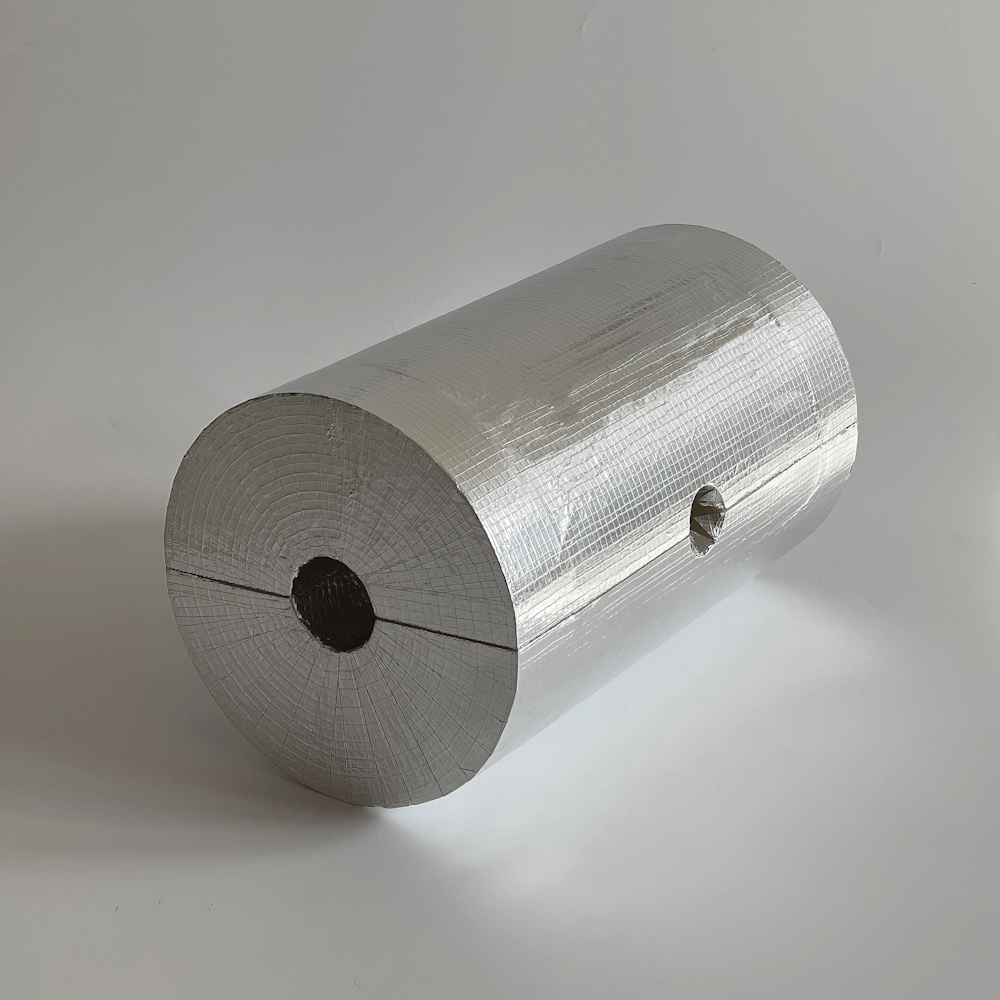

Solid and stable support

Reduces maintenance and ensures long-lasting solutions

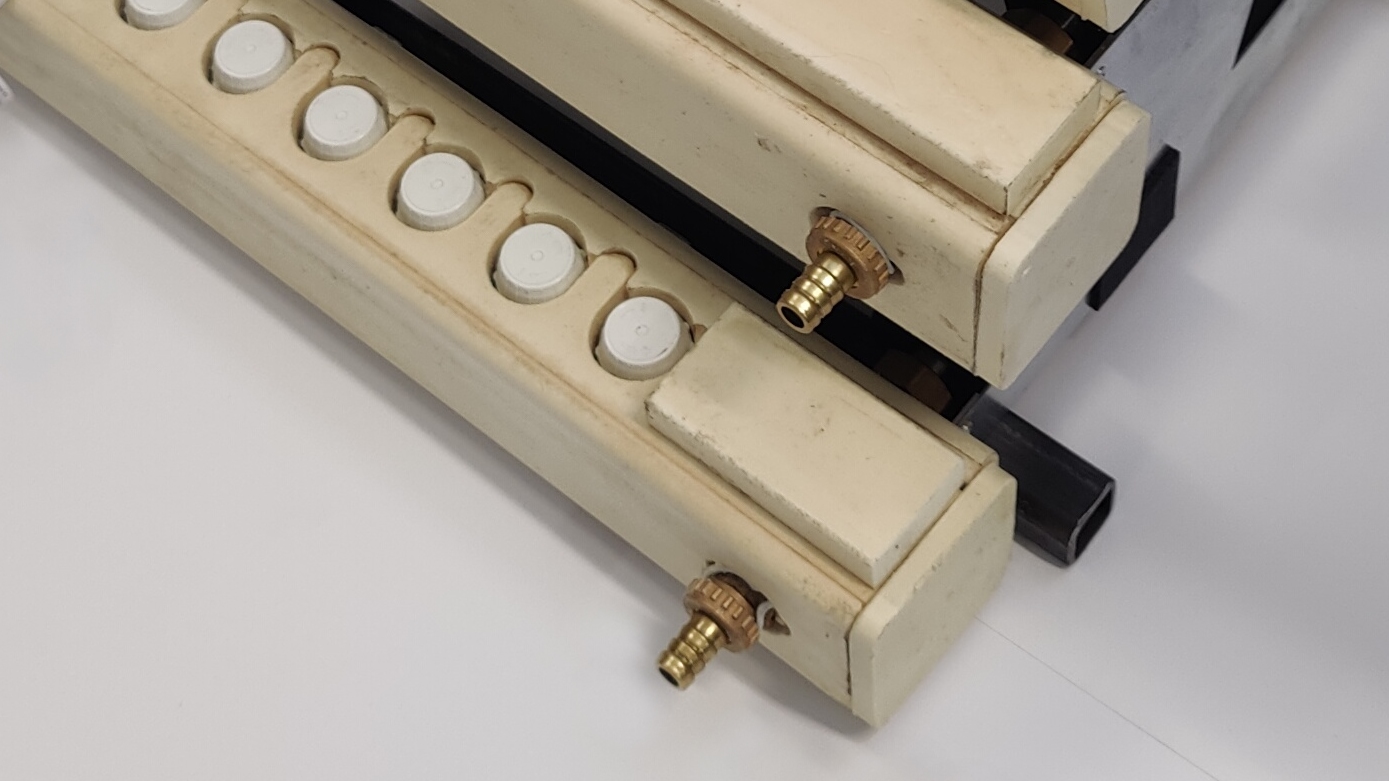

In addition to insulation, PUR and PIR can also be used for building blocks and supports in various building structures. Their dimensional stability ensures that the materials remain effective even under stress, making them reliable choices in piping and other installation areas. This reduces the need for frequent maintenance and ensures long-lasting solutions.

Polyurethane products

Let us assist you

Do you have questions or need help? Please do not hesitate to contact us - we look forward to hearing from you.