What is technical insulation?

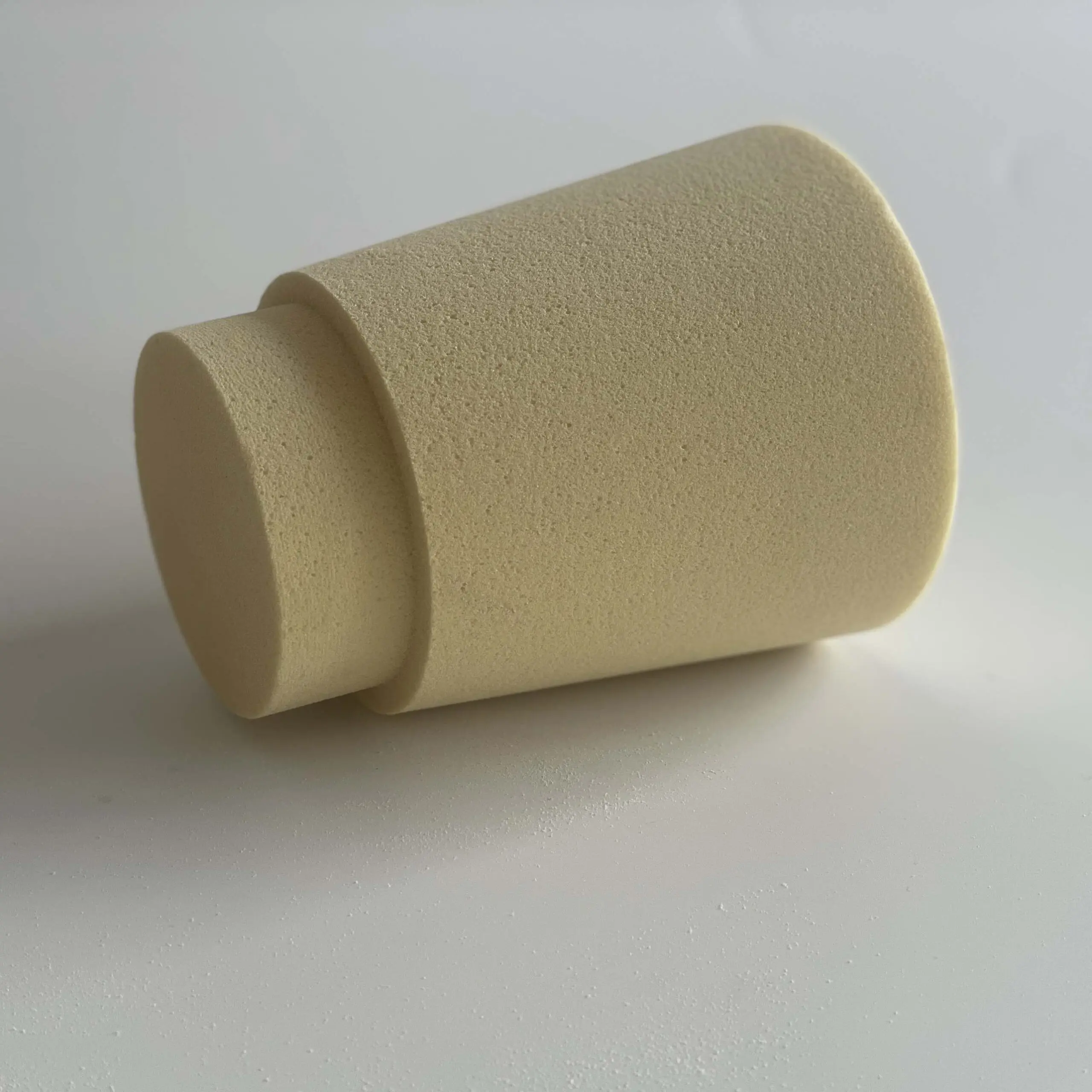

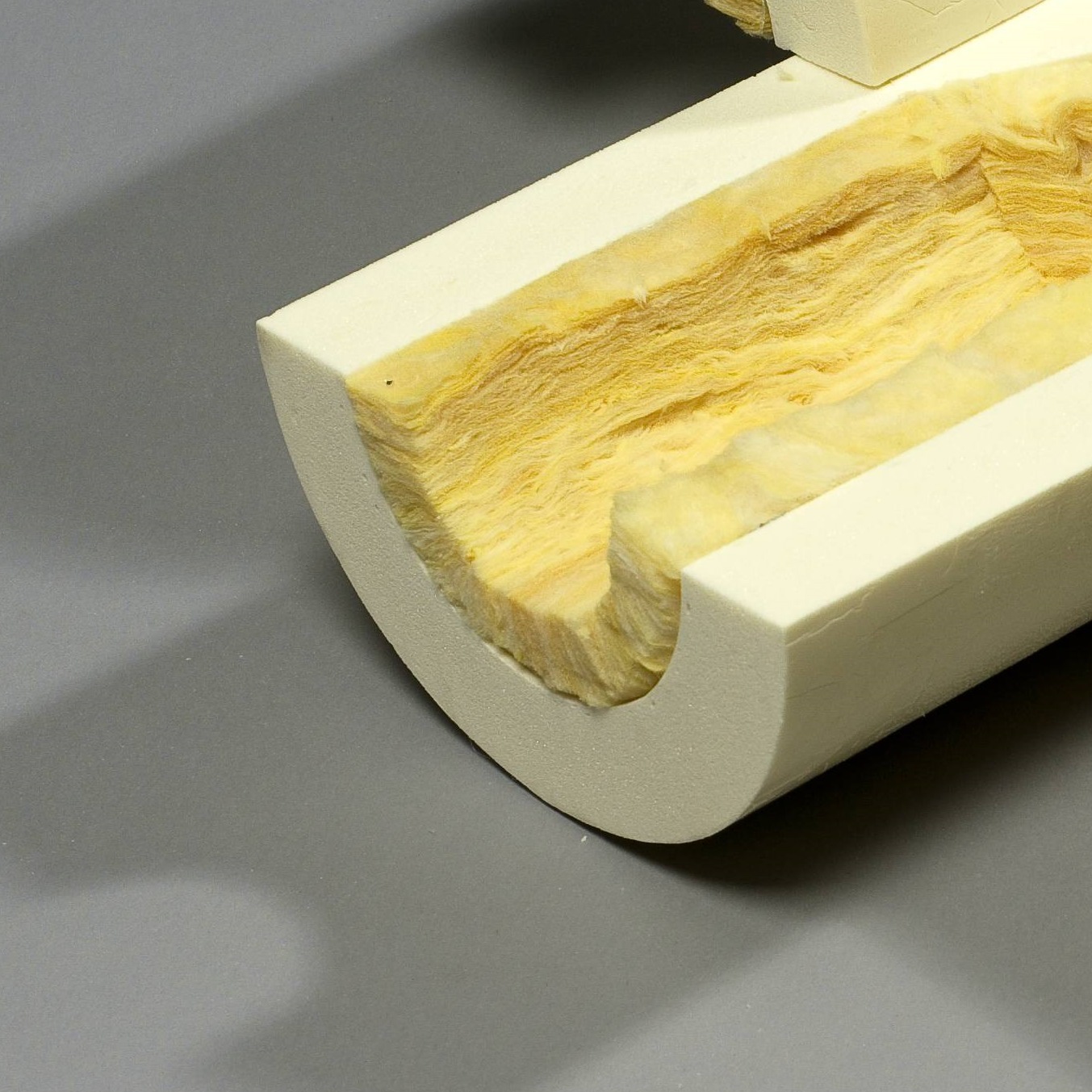

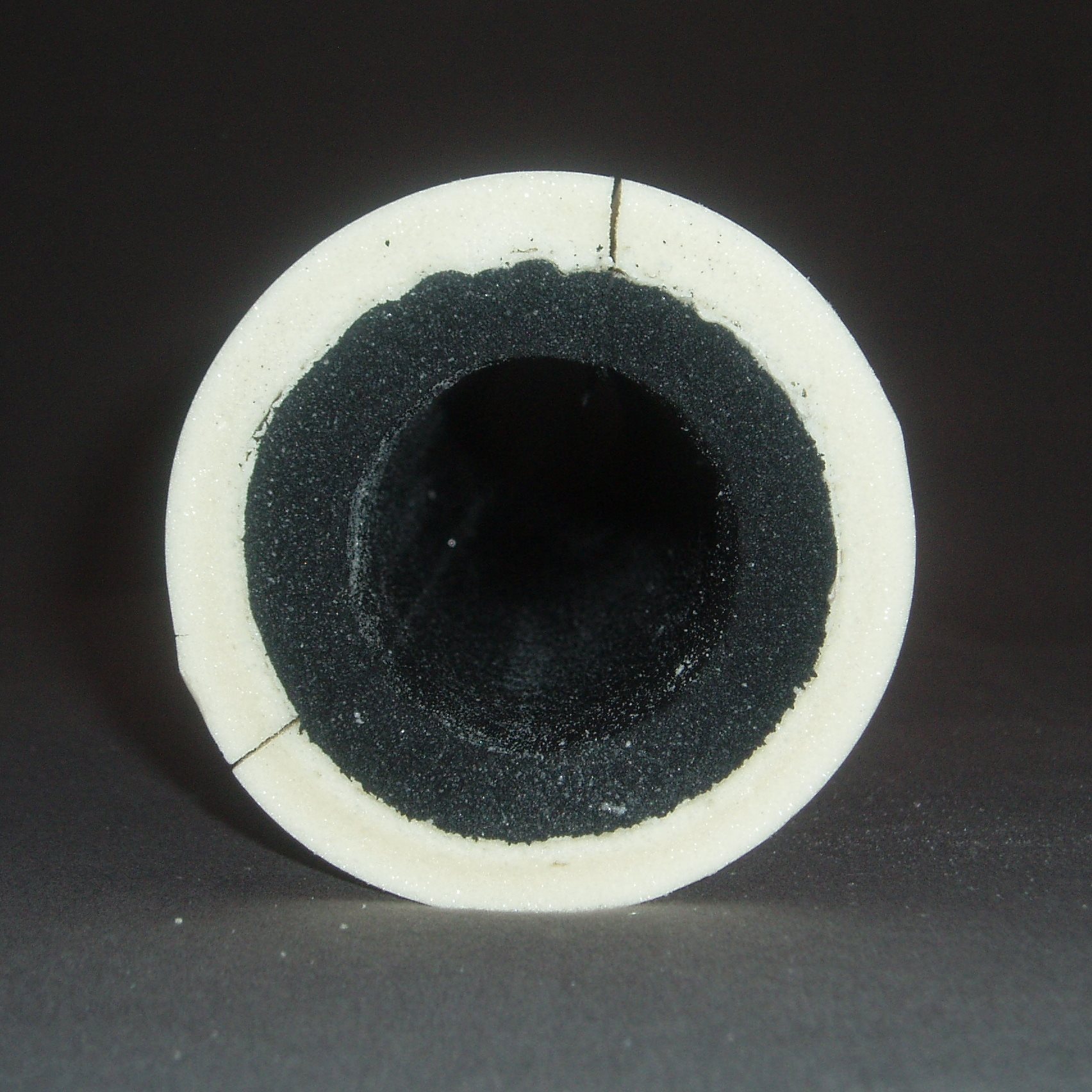

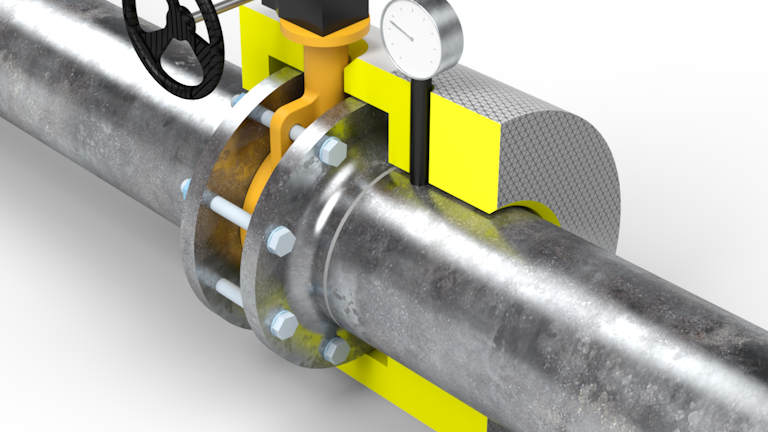

Technical insulation is a process where pipes and systems in technical systems are effectively insulated with polyurethane. This insulation is essential for the systems to function optimally. Technical insulation is used in many types of installations such as heating and cooling systems, ventilation ducts, boilers and vessels, and HVAC systems.

Technical PUR insulation can have multiple functions depending on requirements and needs.

Insulating the building's technical systems with the good properties of polyurethane optimizes energy efficiency, reduces CO2 emissions and lowers operating costs.

Effective insulation is essential to ensure that pipe systems for central heating and air conditioning systems maintain the correct operating temperature. Correct thermal insulation of technical systems reduces energy consumption, reduces the CO2 footprint and creates a healthier indoor climate.

Thermal insulation and energy savings

Thermal insulation helps to minimize heat loss in pipe systems and ensure that energy is used efficiently. By insulating heating systems correctly and effectively, significant savings on energy costs can be achieved while saving CO2.

UV and frost protection

Protect pipes and installations from frost and the sun's UV rays, especially when piping is outside. With a coated polyurethane insulation, damage and potential downtime can be prevented and expensive repairs can be avoided. Technical insulation is therefore an investment that both improves operational efficiency and increases safety.

Soundproofing

Sound insulation is an important factor.

In industrial buildings, where noise from machinery is often already high, technical systems often add further disturbance. Soundproofing the technical systems significantly reduces noise levels, creating a more pleasant working environment and improved productivity.

With PUR insulation, you experience effective noise reduction from technical installations, and the temperature of the system remains stable. Also for places where space is limited, as PUR takes up much less space than other types of insulation.

Polyurethane products

Work with polyurethane foam

Advantages of Rigid Polyurethane Foam (PUR Foam)

Rigid polyurethane foam (PUR foam) is a thermosetting plastic known for its safe handling and use. The material has several advantages that make it a popular choice in industrial and construction engineering applications. One of the most notable features of rigid PUR foam is its ease of handling. It can be easily cut, shaped and adapted to different applications without the need for advanced equipment or technical skills. This feature makes it ideal for both DIY projects and professional applications.

PUR foam is also known for its low weight in relation to its strength and insulating properties. This makes it easy to transport and install, while providing excellent insulation. It is ideal for insulating walls, ceilings, floors in buildings, as well as pipes and technical installations.

Resilience and Energy Efficiency

An important advantage of rigid PUR foam is its resistance to moisture and mold growth. This feature makes it a reliable choice in wet rooms and other environments where humidity may be a concern. Finally, PUR foam is known for its energy efficiency. It provides excellent thermal insulation, which helps to reduce energy consumption and maintain comfortable temperatures indoors. This makes it a greener choice, as it can help reduce energy consumption and CO2 emissions.

Overall, rigid polyurethane foam is a versatile and reliable material that combines ease of handling, strength, insulation and durability. A favorite in the building and construction industry, it provides effective solutions for a wide range of applications.

Safety when foaming polyurethane foam

Safety measures when working with polyurethane

Working with ready-made foam does not require any special safety measures. However, this is not the case when working with polyurethane foam.

Foaming polyurethane involves mixing the raw materials isocyanate and polyol to produce polyurethane foam. From 24 August 2023, appropriate training will be required before industrial or commercial use of products containing more than 0.1% by weight of isocyanates.

Training requirements and courses for safe working with isocyanates

Only persons who have undergone special training may work with polyurethane foaming. The education is offered by institutions for vocational education, such as AMU centers and technical schools.

Employers or self-employed persons who use the products themselves or weld must also have undergone the training before starting work. Everyone who works with isocyanate must complete a two-day course.

In addition, all employees who work with isocyanates and have an increased risk of being exposed to the substance must complete a new AMU course on personal safety. The course lasts 1 day.

Reviewed courses and announcements at Dan-iso a/s

Only persons who have undergone special training may work with polyurethane foaming.

Everyone who works with isocyanate must undergo a two-day course. In addition, all employees who work with isocyanates in a way that may involve an increased risk of being exposed to the substance must in future complete a new AMU course on personal safety. The course has a duration of 1 day.

We have reviewed the following:

- Personal safety when working with epoxy and isocyanates

- Personal safety with isocyanates with increased risk

- Work with epoxy and isocyanate-containing products

- Appendix 3 to the Norwegian Working Environment Authority's order no. 381 of 12 April 2023 on work with substances and materials (chemical agents)

Let us assist you in moving ahead

We are ready to find the solution you need. Do you have questions or need help? Please do not hesitate to contact us - we look forward to hearing from you.