Our employees are the foundation

Dan-iso's foundation

At Dan-iso, we believe that strong results are created by people who thrive – both professionally and personally. That is why employee well-being and decent working conditions are a central part of our strategy and our work with ESG (Environmental, Social & Governance).

A safe and developing working environment

We work every day to create a workplace where safety, respect and openness are in focus. We believe that a good workday is a balanced workday – with room for both professionalism, collaboration and breaks that strengthen the community.

Our employees have access to modern facilities, safe working conditions and an open dialogue with management. It's not just about solving tasks – but about being able to do it with pride, responsibility and job satisfaction.

Well-being is more than just a good day

At Dan-iso, we believe that a strong community grows when we are active together and support each other - both in and outside the workplace.

That's why we support social initiatives, joint activities and events where we can meet across professional and functional areas. This creates relationships, strengthens collaboration and provides a sense of togetherness that spills over into everyday life and the work culture.

Read other related news

Unimaginable special solutions and possibilities in PUR and PIR

The Cimbrer bull stands at the entrance to Friis Shoppingcenter Streetfood in Aalborg. We are thrilled to have contributed to 'shaping'…

Dan-iso invests in solar panels – A step towards a greener future

2024 was concluded with the installation of solar panels at Dan-iso A/S, and we are happy to be able to take this important step towards a greener future.…

Effective insulation of external heat pumps

When it comes to pipe insulation of outdoor heat pumps, precise temperature conditions and material properties play a crucial role in…

The core of our forging department in Havbro

Our forging department's commitment to quality is not just about producing strong and reliable molds – it also helps reduce material…

Energy optimization in the district heating sector

In a world where energy optimization and sustainable solutions have become our shared responsibility, insulation plays a major role. When we talk about…

Centrifugal Pump Insulation: The Overlooked Key to Efficient Operation

As the industry increasingly focuses on energy efficiency and sustainable solutions, it is no longer enough to just insulate pipes. A…

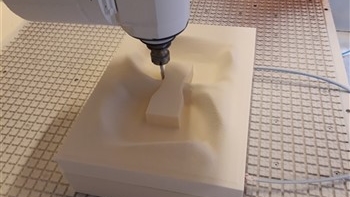

Unimaginable special solutions and possibilities in PUR and PIR

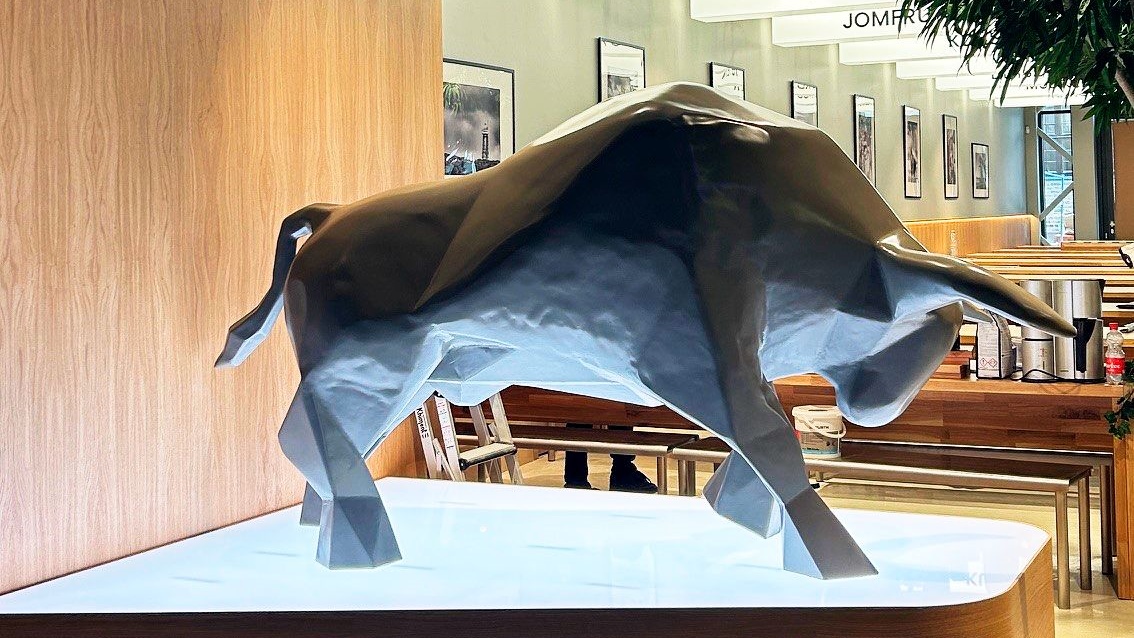

A proud Cimbrian bull in Aalborg

The Cimbre bull stands proudly and enthroned at the entrance to Friis Shopping Center Streetfood in Aalborg.

We are thrilled to have helped to 'mold' the Streetfood bull in PUR (polyurethane) using our CNC machine. This project highlights the versatility and excellent properties of PUR for prototyping.

At Dan-iso, we mill self-produced block foam materials and work with a wide range of common materials such as wood, nylon PET, EPS and customer-supplied materials.

We are very proud of the hard work of our Dan-iso team and look forward to more exciting projects.

Read other related news

Our employees are the foundation

Strong results are created by people who thrive – both professionally and personally. Therefore, employee well-being and proper working conditions are a…

Dan-iso invests in solar panels – A step towards a greener future

2024 was concluded with the installation of solar panels at Dan-iso A/S, and we are happy to be able to take this important step towards a greener future.…

Effective insulation of external heat pumps

When it comes to pipe insulation of outdoor heat pumps, precise temperature conditions and material properties play a crucial role in…

The core of our forging department in Havbro

Our forging department's commitment to quality is not just about producing strong and reliable molds – it also helps reduce material…

Energy optimization in the district heating sector

In a world where energy optimization and sustainable solutions have become our shared responsibility, insulation plays a major role. When we talk about…

Centrifugal Pump Insulation: The Overlooked Key to Efficient Operation

As the industry increasingly focuses on energy efficiency and sustainable solutions, it is no longer enough to just insulate pipes. A…

Dan-iso invests in solar panels – A step towards a greener future

Responsible production

2024 was concluded with the installation of solar panels at Dan-iso A/S, and we are happy to be able to take this important step towards a greener future.

This investment marks our continued commitment to sustainability and energy efficiency.

Responsible production

Responsible production is a key area for Dan-iso A/S, and we are proud to take concrete steps towards creating a greener future. In 2024, we were pleased to complete the installation of solar panels at our production facilities. This investment is an important step in our continued work with sustainability and energy efficiency. We have always focused on responsible production. With this solar cell installation, we are taking another step towards reducing our CO2 footprint and optimizing our energy consumption.

The solar panels will not only help us reduce our dependence on fossil fuels. We will also ensure that we use renewable energy to power our production of technical insulation, including PUR and PIR pipe insulation. This is a significant step towards ensuring a sustainable future for both us and our customers. When it comes to technical insulation, it is important to choose materials that are efficient and long-lasting. PUR and PIR pipe insulation are ideal solutions as they offer excellent insulation. At the same time, it is a step towards reducing energy consumption in buildings and industrial plants.

Optimizing energy efficiency

PUR and PIR pipe insulation plays an important role in our production processes as it helps to optimise energy efficiency. Our technical insulation with PUR and PIR materials ensures that heat is not lost, which helps to reduce energy consumption and promote sustainability. It is crucial for us to be able to deliver insulation solutions that not only meet the technical requirements, but also support our overall goal of creating a greener future.

Technical insulation such as PUR and PIR pipe insulation is not only important for the energy efficiency of buildings, but also plays a significant role in industrial production. By using technical insulation with PUR and PIR, we can ensure that the pipes that transport heat or cooling maintain the desired temperature. This reduces energy losses and improves overall efficiency. Our continued investment in energy-efficient technology is a clear signal that we are taking responsibility and actively working to reduce our environmental impact.

Use of renewable energy for production

We have chosen to integrate solar energy into our production of technical insulation, including PUR and PIR pipe insulation, as a way to optimize our production. The renewable energy we generate from the solar panels helps support a more efficient and responsible production of our insulation materials. This is an important step in our work to reduce energy consumption in our production facilities and ensure that we can offer our customers sustainable solutions.

As a responsible manufacturer, we see it as our duty to invest in solutions that are both energy efficient and responsible. PUR and PIR pipe insulation is part of our strategy to promote responsibility and help our customers achieve energy efficiency in their buildings and facilities. Our technical insulation helps ensure that energy is not wasted, resulting in lower energy consumption and costs for our customers.

Energy-efficient and long-lasting insulation solutions

In the future, we see a continued focus on sustainability, and we are determined to remain at the forefront when it comes to developing energy-efficient and long-lasting solutions. Our work with technical insulation and the installation of solar panels are just the beginning of a long series of initiatives that will help us achieve our goal of more energy-efficient production. We are proud of the steps we have taken and look forward to continuing to develop solutions that create value for both our customers and the environment.

Together with our customers and partners, we are ready to continue our work to create a more sustainable future through responsible production and technical insulation. We hope that our investments in solar energy and energy efficiency will inspire others to take similar steps towards a greener future.

Read other related news

Our employees are the foundation

Strong results are created by people who thrive – both professionally and personally. Therefore, employee well-being and proper working conditions are a…

Unimaginable special solutions and possibilities in PUR and PIR

The Cimbrer bull stands at the entrance to Friis Shoppingcenter Streetfood in Aalborg. We are thrilled to have contributed to 'shaping'…

Effective insulation of external heat pumps

When it comes to pipe insulation of outdoor heat pumps, precise temperature conditions and material properties play a crucial role in…

The core of our forging department in Havbro

Our forging department's commitment to quality is not just about producing strong and reliable molds – it also helps reduce material…

Energy optimization in the district heating sector

In a world where energy optimization and sustainable solutions have become our shared responsibility, insulation plays a major role. When we talk about…

Centrifugal Pump Insulation: The Overlooked Key to Efficient Operation

As the industry increasingly focuses on energy efficiency and sustainable solutions, it is no longer enough to just insulate pipes. A…

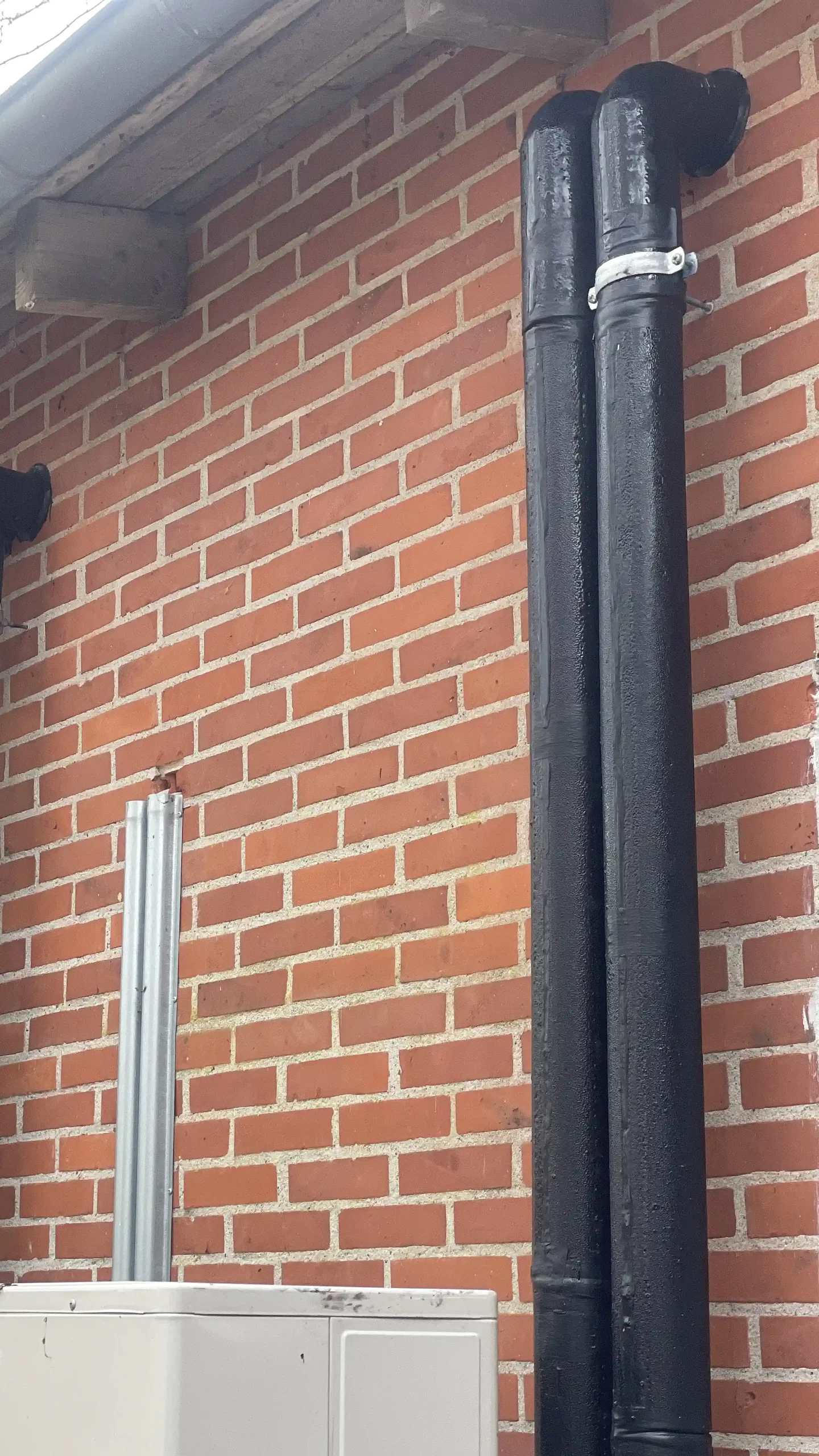

Effective insulation of external heat pumps

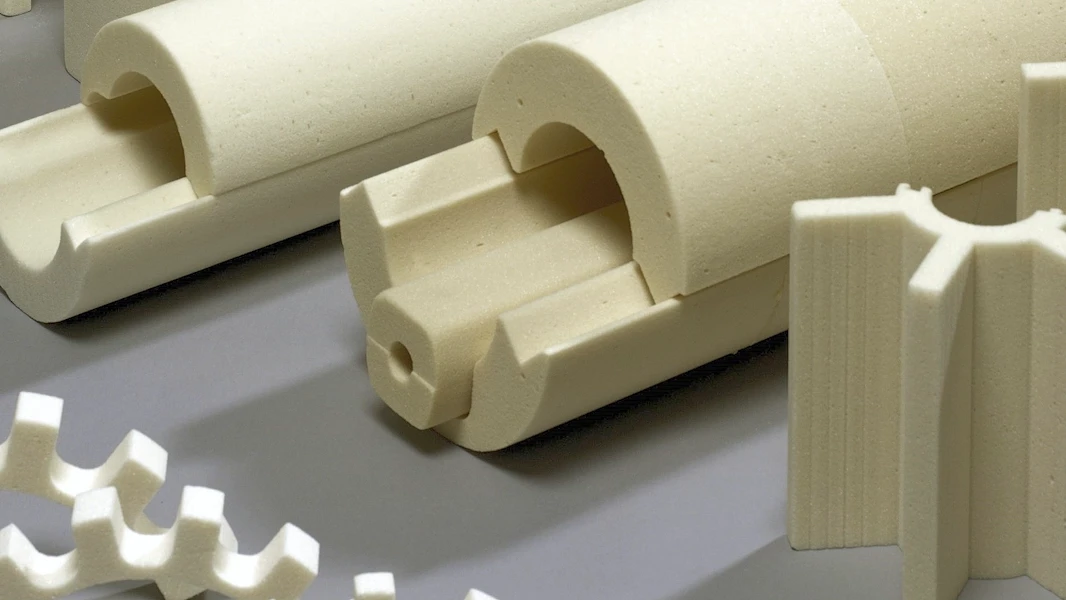

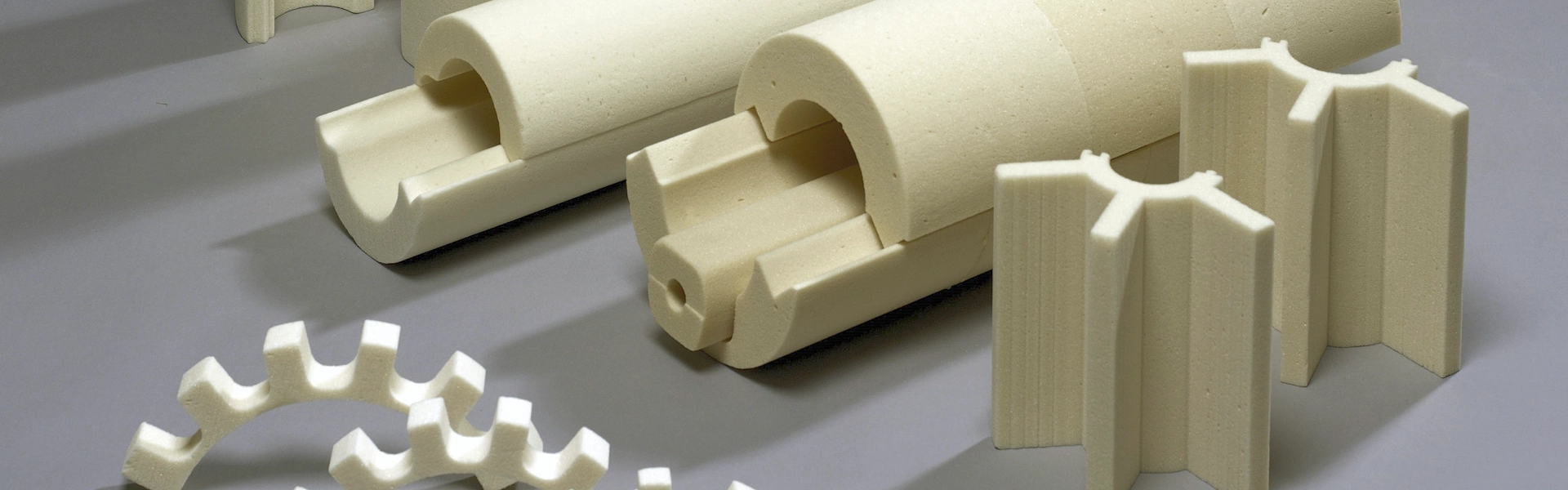

Effective insulation of external heat pumps: Molded PUR pipe insulation ensures an optimal solution

When it comes to pipe insulation for outdoor heat pumps, precise temperature conditions and material properties play a crucial role in efficiency. Instead of using spray foam directly on outdoor pipes – a process that can be challenging in fluctuating temperatures – the UV-protected and coated molded pipe shell is a much more durable and stable solution.

Robust coating

Molded polyurethane foam pipe insulation is specifically designed for outdoor use. The cups come with a robust UV-protective coating that protects against degradation from the sun's rays while maintaining stable insulation performance in all weather conditions.

Advantages of this solution include optimal insulation performance, as the PUR material has a very low thermal conductivity, which effectively reduces heat loss. The combination with molding ensures a tight fit around pipes and wires, which further improves the insulation effect.

Outdoor installations

The outer coating makes the pipe shell UV-resistant and durable. The coating protects the pipe shell from sunlight and prevents the insulation from degrading over time, which is especially important in outdoor installations where the material is exposed to weather factors.

Pre-molded pipe cups are easy to install as they are pre-cut and adapted to standard pipe sizes. This makes installation both quick and simple, while minimizing the risk of errors.

Close monitoring

Another advantage of this solution is that it ensures consistent insulation in all conditions. Unlike spray insulation, which requires close monitoring of temperature and humidity, the tube trays provide reliable and consistent results, even in difficult outdoor conditions.

By using molded and UV-coated PUR pipe shells from Dan-iso, you achieve effective and durable insulation of your heat pump's outdoor pipes. This solution eliminates challenges associated with temperature requirements for spray foam and ensures uniform insulation, improving the system's energy efficiency.

For homeowners and professionals looking for a professional and reliable solution, molded pipe bowls are an investment that benefits both the environment and the wallet in the long term.

Generally speaking, it is not necessary to insulate the entire heat pump, but there are certain components that may benefit from insulation.

Pipes and pipe connections:

It is important to insulate the pipes that transport the refrigerant and possibly water, especially if these are exposed to low temperatures. Insulating the pipes prevents heat loss and ensures that the heat pump works efficiently.

Compressor:

The compressor in an outdoor heat pump can generate a lot of heat and should have appropriate insulation to ensure that the heat pump does not lose too much heat to the surroundings.

Frost protection:

During the winter months it is important to protect certain parts of the heat pump that may be exposed to frost damage. Proper pipe insulation can help maintain efficient operation even at low temperatures.

In general, it is always a good idea to follow the heat pump manufacturer's instructions on pipe insulation to maximize the heat pump's efficiency and extend its lifespan.

The installation process for PUR pipe bowls

1. Preparation:

• Make sure the pipes are clean and dry before installation.

• Avoid areas with blockages so that the bowls can be positioned correctly.

2. Placement of pipe bowls:

• The bowls are opened and placed tightly around the tube.

• Ensure that all joints are aligned correctly to minimize heat loss.

3. Fastening and sealing:

• Use weatherproof tape or mounting tape to seal the joints.

• Any open areas are sealed with PUR glue or weather-resistant sealant.

Read other related news

Our employees are the foundation

Strong results are created by people who thrive – both professionally and personally. Therefore, employee well-being and proper working conditions are a…

Unimaginable special solutions and possibilities in PUR and PIR

The Cimbrer bull stands at the entrance to Friis Shoppingcenter Streetfood in Aalborg. We are thrilled to have contributed to 'shaping'…

Dan-iso invests in solar panels – A step towards a greener future

2024 was concluded with the installation of solar panels at Dan-iso A/S, and we are happy to be able to take this important step towards a greener future.…

The core of our forging department in Havbro

Our forging department's commitment to quality is not just about producing strong and reliable molds – it also helps reduce material…

Energy optimization in the district heating sector

In a world where energy optimization and sustainable solutions have become our shared responsibility, insulation plays a major role. When we talk about…

Centrifugal Pump Insulation: The Overlooked Key to Efficient Operation

As the industry increasingly focuses on energy efficiency and sustainable solutions, it is no longer enough to just insulate pipes. A…

The core of our forging department in Havbro

Quality and sustainability: Our forging department ensures the durability of our molds

At Dan-iso we are proud of the quality of our in-house produced molds, which are manufactured with precision and expertise by our skilled forging department in Havbro. With many years of experience, our team combines accuracy with a keen eye for detail to ensure that each mold meets our high standards.

Our forging department’s commitment to quality is not just about producing strong and reliable molds – it also helps reduce material and energy waste, making our processes more efficient and sustainable. Every weld, every joint, and every touch reflects our dedication to craftsmanship.

At Dan-iso, we are also committed to promoting innovation and social responsibility through sustainable production methods and working conditions. This includes ensuring health, safety and equal opportunities for all our employees.

Our focus on responsibility also extends to the UN's Sustainable Development Goals, especially Goal 7 (Sustainable Energy), Goal 8 (Decent Work and Economic Growth), Goal 9 (Industry, Innovation and Infrastructure), Goal 12 (Responsible Consumption and Production) and Goal 13 (Climate Action).

You can rely on the expertise of our team, who work behind the scenes to ensure that our products live up to the values we stand for.

Read other related news

Our employees are the foundation

Strong results are created by people who thrive – both professionally and personally. Therefore, employee well-being and proper working conditions are a…

Unimaginable special solutions and possibilities in PUR and PIR

The Cimbrer bull stands at the entrance to Friis Shoppingcenter Streetfood in Aalborg. We are thrilled to have contributed to 'shaping'…

Dan-iso invests in solar panels – A step towards a greener future

2024 was concluded with the installation of solar panels at Dan-iso A/S, and we are happy to be able to take this important step towards a greener future.…

Effective insulation of external heat pumps

When it comes to pipe insulation of outdoor heat pumps, precise temperature conditions and material properties play a crucial role in…

Energy optimization in the district heating sector

In a world where energy optimization and sustainable solutions have become our shared responsibility, insulation plays a major role. When we talk about…

Centrifugal Pump Insulation: The Overlooked Key to Efficient Operation

As the industry increasingly focuses on energy efficiency and sustainable solutions, it is no longer enough to just insulate pipes. A…

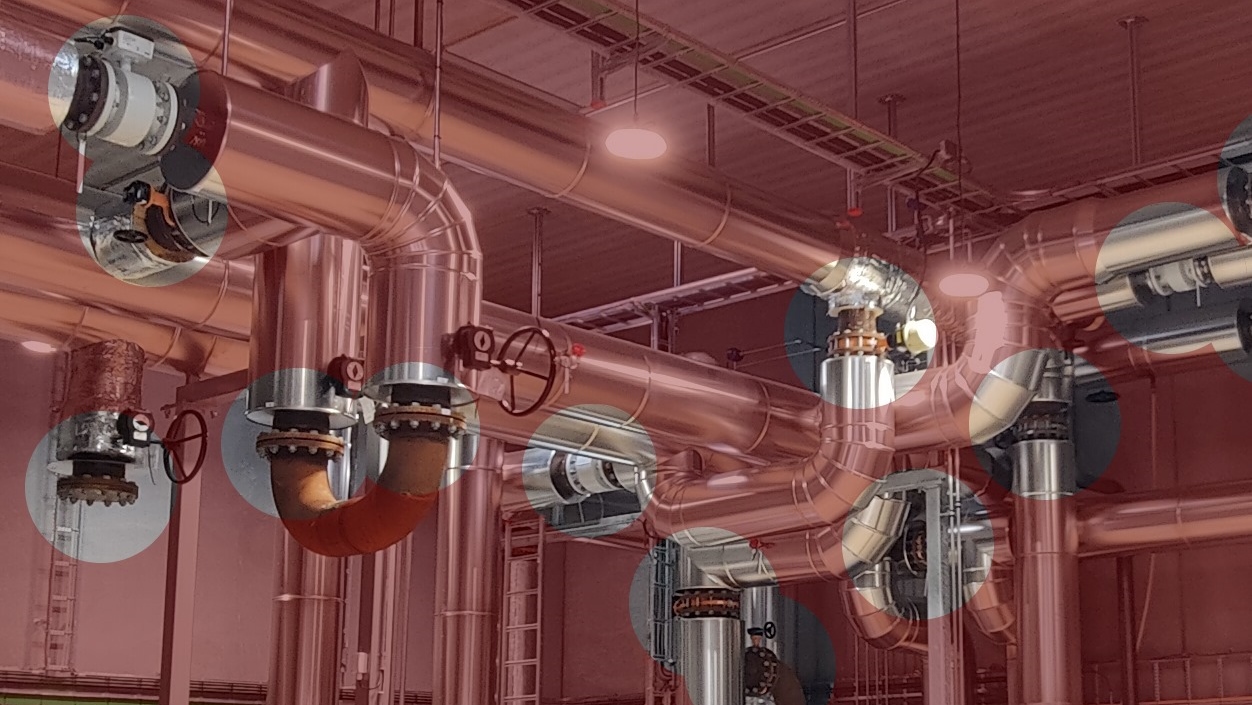

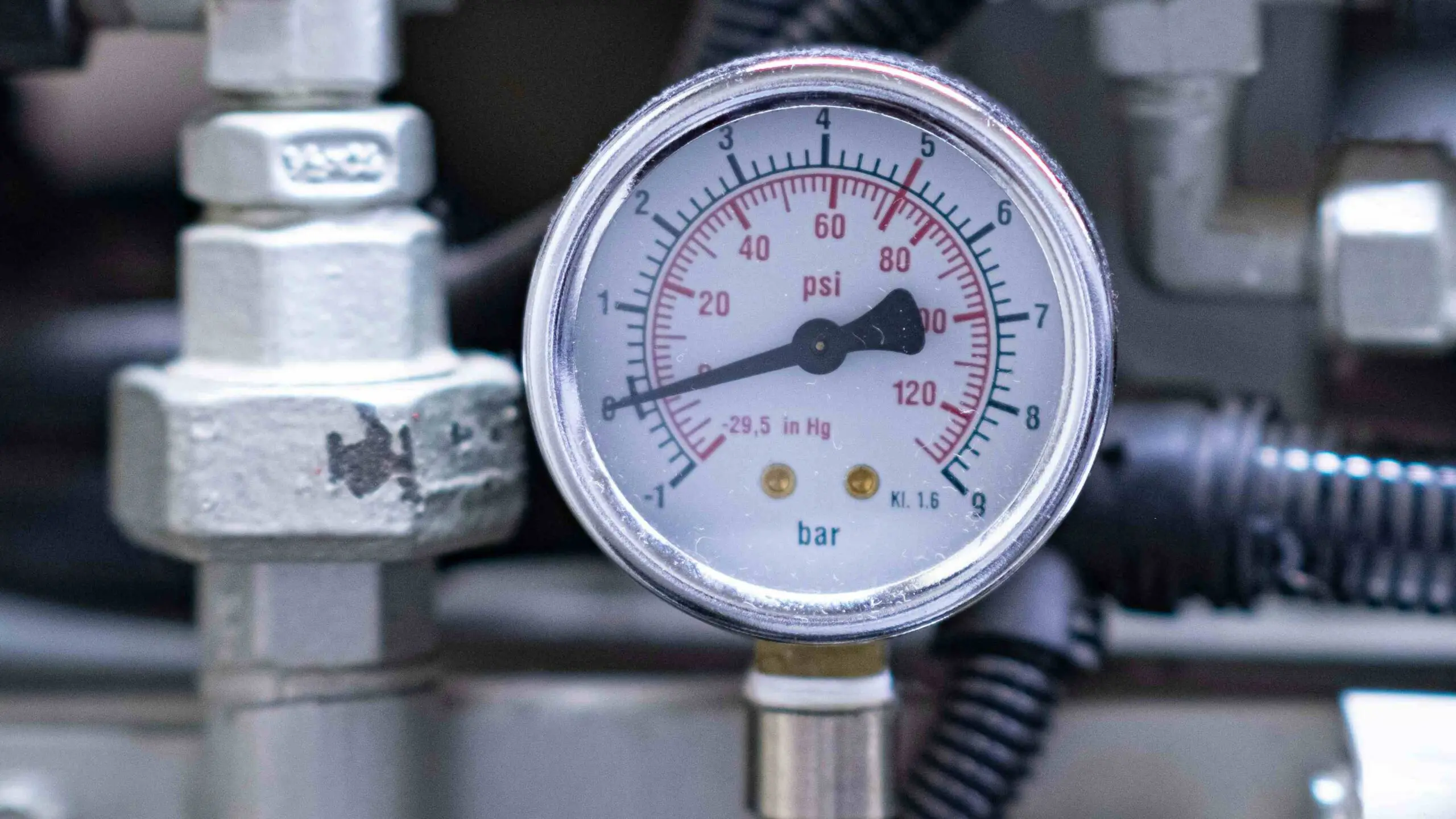

Energy optimization in the district heating sector

Tailor-made insulation solutions for valves and pumps!

In a world where energy optimization and sustainable solutions have become our shared responsibility, insulation plays a major role.

When we talk about effective insulation, it means that no energy is lost on pipes, flanges and pumps, thus also saving money on operations and ensuring that our resources are used wisely. It is an investment that benefits security of supply, the individual economy and the climate.

Polyurethane is among the most effective insulation solutions on the market and possesses particular advantages. PUR and PIR stand out with their technical thermal properties. This makes PUR an ideal choice for heating systems where long-term reliability and efficiency are essential.

Download our 'White Paper' that explores how Dan-isoFIT pipe insulation, an innovative insulation product, can play a crucial role in reducing CO2 emissions, saving energy and significantly lowering operating costs.

Read other related news

Our employees are the foundation

Strong results are created by people who thrive – both professionally and personally. Therefore, employee well-being and proper working conditions are a…

Unimaginable special solutions and possibilities in PUR and PIR

The Cimbrer bull stands at the entrance to Friis Shoppingcenter Streetfood in Aalborg. We are thrilled to have contributed to 'shaping'…

Dan-iso invests in solar panels – A step towards a greener future

2024 was concluded with the installation of solar panels at Dan-iso A/S, and we are happy to be able to take this important step towards a greener future.…

Effective insulation of external heat pumps

When it comes to pipe insulation of outdoor heat pumps, precise temperature conditions and material properties play a crucial role in…

The core of our forging department in Havbro

Our forging department's commitment to quality is not just about producing strong and reliable molds – it also helps reduce material…

Centrifugal Pump Insulation: The Overlooked Key to Efficient Operation

As the industry increasingly focuses on energy efficiency and sustainable solutions, it is no longer enough to just insulate pipes. A…

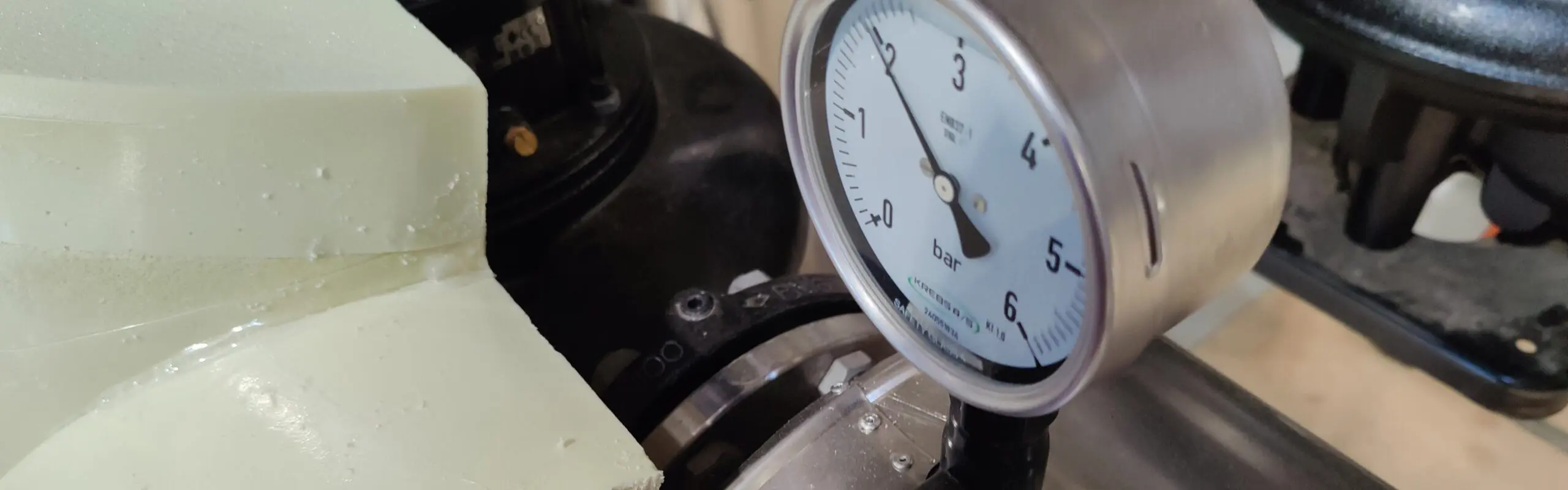

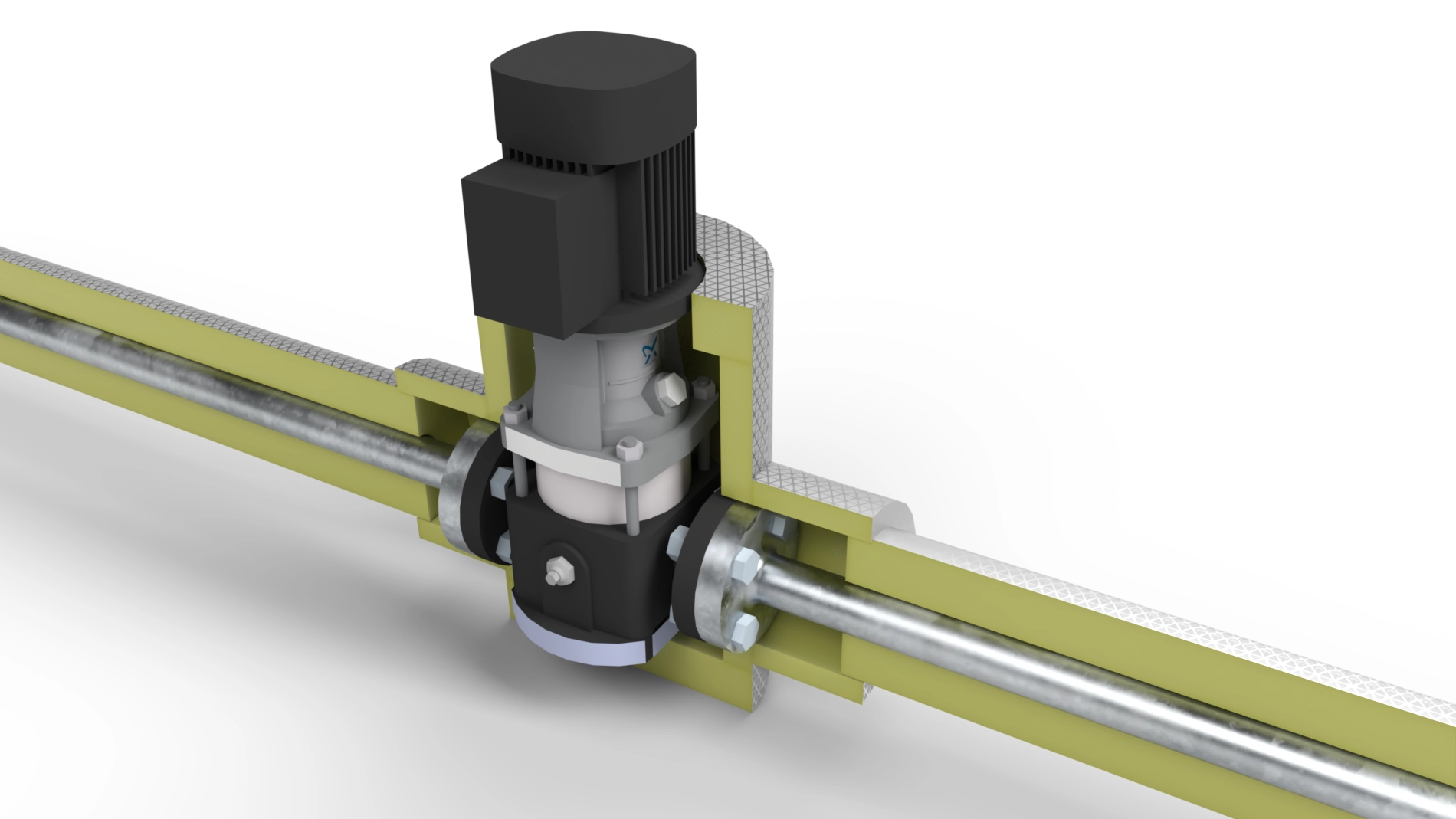

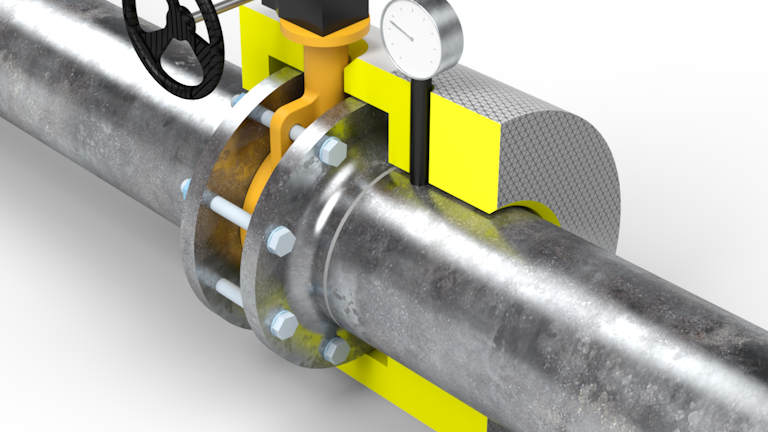

Centrifugal Pump Insulation: The Overlooked Key to Efficient Operation

As the industry increasingly focuses on energy efficiency and sustainable solutions, it is no longer enough to simply insulate pipes. One often overlooked but highly effective method to reduce energy consumption and improve operational efficiency is insulating industrial pumps – especially the indispensable centrifugal pumps.

Heat Loss = Money Lost

Centrifugal pumps are a cornerstone of many industrial systems. They are used to efficiently transport large volumes of fluids under pressure and are found in everything from water supply and wastewater treatment to chemical production and district heating. While their mechanical operation is efficient, a hidden energy drain lies in their design: the large surface area.

When the fluid in the system is hot – for example, in district heating or process plants – the pump surface acts as an efficient heat emitter to the surroundings. This results in valuable energy being lost, and the system must use extra resources to compensate for this heat loss.

PUR insulation: A simple solution with significant impact

By insulating the pumps, heat loss can be significantly reduced. Effective insulation retains the energy of the fluid and prevents it from escaping into the surrounding environment. This not only leads to lower energy costs but also improves the operational efficiency and stability of the entire system.

Industry analyses show that proper pump insulation can reduce energy consumption by up to 20-30%, depending on the application and pump size. This translates directly into cost savings, especially in energy-intensive industries.

More than just energy savings

PUR (polyurethane) pipe insulation also offers mechanical benefits. It protects pump components from extreme temperatures and reduces the risk of overheating. This extends the lifespan of the equipment and reduces the need for maintenance and replacement of parts. In other words, technical pipe insulation is not just an energy-saving solution – it's also an investment in operational reliability.

Insulating the entire system – not just the pipes

In many installations, the focus is on insulating the pipes – and for good reason. Pipes represent a significant portion of the surface area where heat can be lost. However, in the rush to optimize pipe insulation, pumps and flanges are often overlooked. This can be a costly mistake.

At Dan-iso A/S, we specialize in PUR and PIR insulation solutions that cover the entire system – pipes, pumps, and flanges. Our experience shows that it’s only when all components are properly insulated that the full savings potential is realized.

Centrifugal pumps – A vital component of energy-saving systems

Centrifugal pumps are known for their reliability and ability to handle large volumes of liquid under pressure. However, their design – with a large surface area and constant operation – makes them particularly vulnerable to energy loss. Insulation is not an option here; it’s a necessity for operating a modern, energy-efficient system.

Conclusion: Don’t overlook the pumps

In the pursuit of energy savings and sustainable solutions, it’s important to consider the whole picture. Pipe insulation is crucial, but without a corresponding focus on pumps and flanges, the full benefits won’t be realized.

We work to ensure that the entire thermal system operates optimally. With custom-made PUR and PIR pipe insulation solutions for centrifugal pumps, we help companies save energy, protect their equipment, and support the green transition.

Read other related news

Our employees are the foundation

Strong results are created by people who thrive – both professionally and personally. Therefore, employee well-being and proper working conditions are a…

Unimaginable special solutions and possibilities in PUR and PIR

The Cimbrer bull stands at the entrance to Friis Shoppingcenter Streetfood in Aalborg. We are thrilled to have contributed to 'shaping'…

Dan-iso invests in solar panels – A step towards a greener future

2024 was concluded with the installation of solar panels at Dan-iso A/S, and we are happy to be able to take this important step towards a greener future.…

Effective insulation of external heat pumps

When it comes to pipe insulation of outdoor heat pumps, precise temperature conditions and material properties play a crucial role in…

The core of our forging department in Havbro

Our forging department's commitment to quality is not just about producing strong and reliable molds – it also helps reduce material…

Energy optimization in the district heating sector

In a world where energy optimization and sustainable solutions have become our shared responsibility, insulation plays a major role. When we talk about…

June 2025

Newsletter – June 2025

Welcome to the June edition of Dan-iso's newsletter!

In this edition you can read about:

-

New case story – "The flow meters work with high accuracy...”

-

Article: Centrifugal Pump Insulation – the overlooked key to efficient operations.

-

Summer 2025 – We will continue to skim all summer.

Click below to read the entire newsletter:

Collaboration on a professionally based website for technical insulation

The development of our new website took place in close collaboration with Sky Solution, where the focus from the start was to create a platform that matches the needs of professionals within technical insulation and pipe insulation.

We worked hard to build a product catalog that is logically divided – both by product type and industry. This makes it quick for insulators, consultants and purchasers to find precisely the solutions that are relevant to their specific projects – whether it concerns the district heating industry, the process industry or molded special insulation solutions.

The collaboration with Sky Solution has been characterized by great professional understanding and an openness to ongoing adjustments. It has given us a flexible website that can be expanded as our product range and customer types develop – without compromising structure or usability.

Read other related news

Our employees are the foundation

Strong results are created by people who thrive – both professionally and personally. Therefore, employee well-being and proper working conditions are a…

Unimaginable special solutions and possibilities in PUR and PIR

The Cimbrer bull stands at the entrance to Friis Shoppingcenter Streetfood in Aalborg. We are thrilled to have contributed to 'shaping'…

Dan-iso invests in solar panels – A step towards a greener future

2024 was concluded with the installation of solar panels at Dan-iso A/S, and we are happy to be able to take this important step towards a greener future.…

Effective insulation of external heat pumps

When it comes to pipe insulation of outdoor heat pumps, precise temperature conditions and material properties play a crucial role in…

The core of our forging department in Havbro

Our forging department's commitment to quality is not just about producing strong and reliable molds – it also helps reduce material…

Energy optimization in the district heating sector

In a world where energy optimization and sustainable solutions have become our shared responsibility, insulation plays a major role. When we talk about…

Cooperation in the PUR Section of the Danish Plastics Industry - effektivisolering.dk

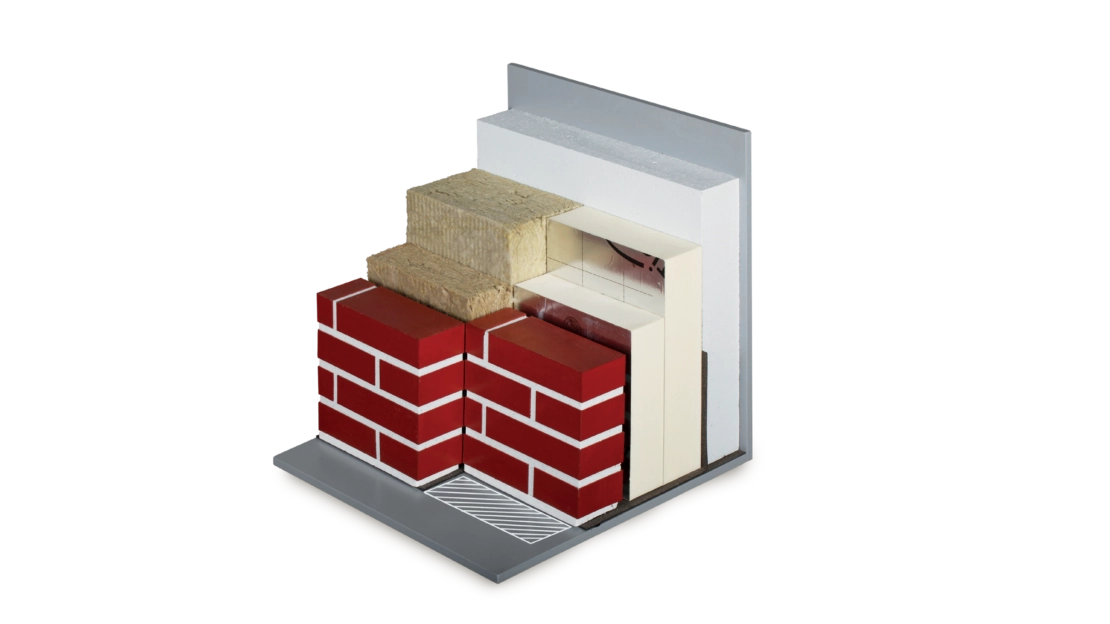

The PUR section's insulation companies are constantly working to spread awareness of the use of polyurethane insulation products in construction.

In this connection, a collection of examples has been produced to show the many advantages and inspire the use of PIR/PUR insulation in construction.

POLYURETHANE INSULATION IN CONSTRUCTION - COLLECTION OF EXAMPLES

Read other related news

Our employees are the foundation

Strong results are created by people who thrive – both professionally and personally. Therefore, employee well-being and proper working conditions are a…

Unimaginable special solutions and possibilities in PUR and PIR

The Cimbrer bull stands at the entrance to Friis Shoppingcenter Streetfood in Aalborg. We are thrilled to have contributed to 'shaping'…

Dan-iso invests in solar panels – A step towards a greener future

2024 was concluded with the installation of solar panels at Dan-iso A/S, and we are happy to be able to take this important step towards a greener future.…

Effective insulation of external heat pumps

When it comes to pipe insulation of outdoor heat pumps, precise temperature conditions and material properties play a crucial role in…

The core of our forging department in Havbro

Our forging department's commitment to quality is not just about producing strong and reliable molds – it also helps reduce material…

Energy optimization in the district heating sector

In a world where energy optimization and sustainable solutions have become our shared responsibility, insulation plays a major role. When we talk about…

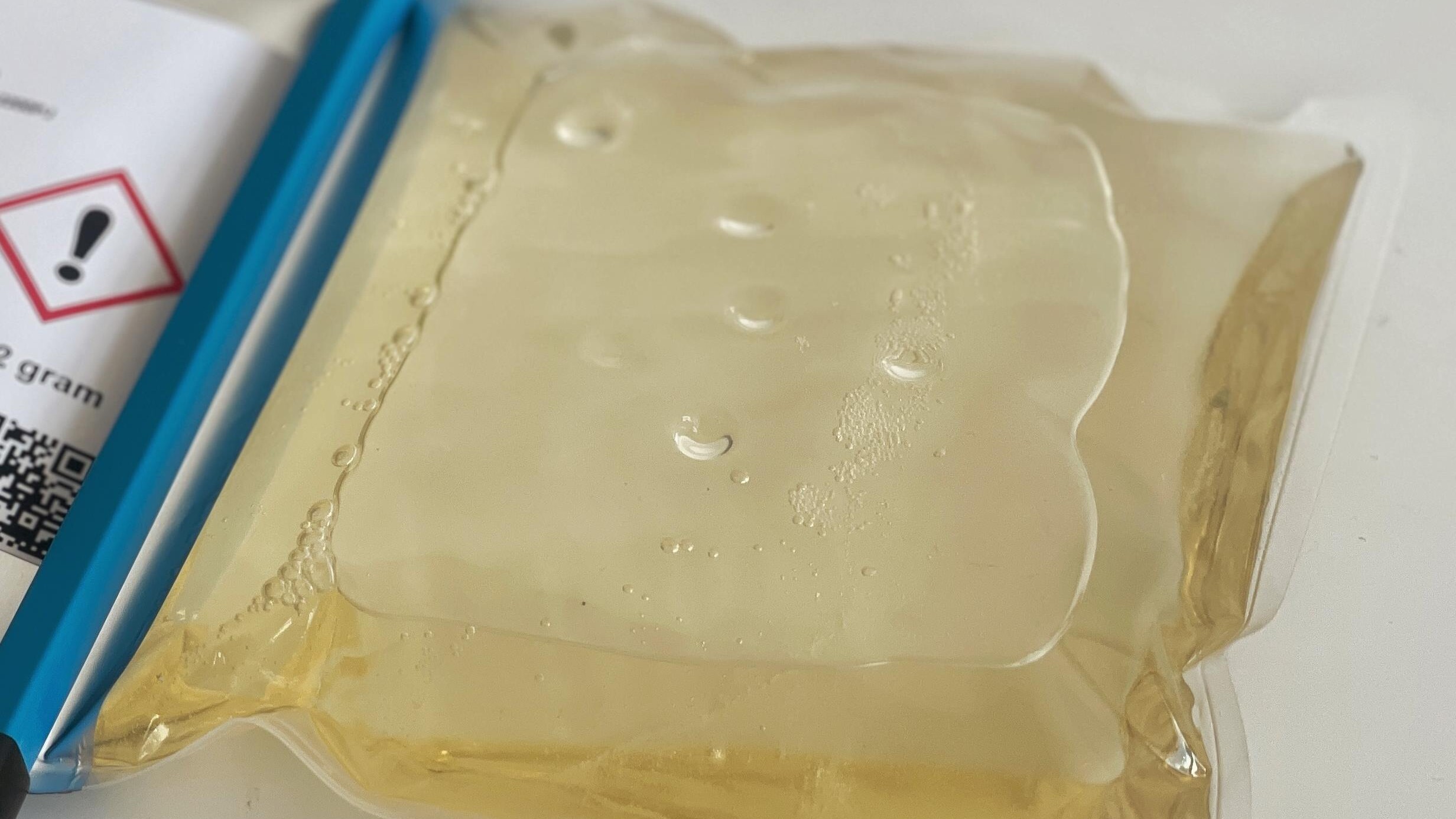

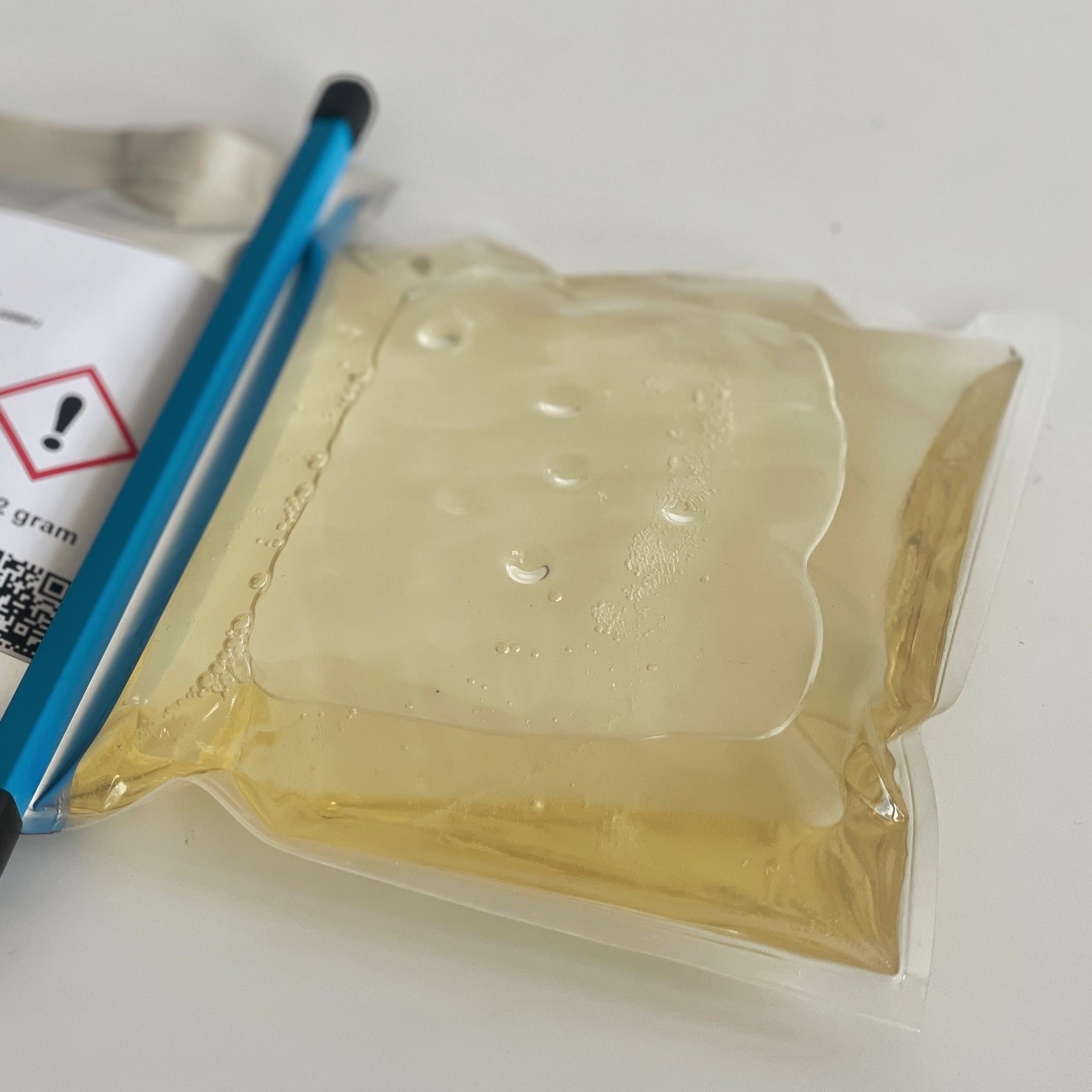

Working with polyurethane – focus on safety and correct handling

Working with polyurethane – focus on safety and correct handling

Safety measures when working with polyurethane

Working with ready-made foam does not require any special safety measures. However, this is not the case when working with polyurethane foam. Foaming polyurethane involves mixing the raw materials isocyanate and polyol to produce polyurethane foam. From 24 August 2023, appropriate training will be required before industrial or commercial use of products containing more than 0.1% by weight of isocyanates.

Training requirements and courses for safe working with isocyanates

Only persons who have undergone special training may work with polyurethane foaming. The education is offered by institutions for vocational education, such as AMU centers and technical schools.

Employers or self-employed persons who use the products themselves or weld must also have undergone the training before starting work. Everyone who works with isocyanate must complete a two-day course.

All employees who work with isocyanates and have an increased risk of exposure to the substance must complete a specific AMU course on personal safety. The course lasts 1 day.

General courses and announcements completed at Dan-iso a/s

- Personal safety when working with epoxy and isocyanates

- Personal safety with isocyanates with increased risk

- Work with epoxy and isocyanate-containing products

- Appendix 3 to the Norwegian Working Environment Authority's order no. 381 of 12 April 2023 on work with substances and materials (chemical agents)

Advantages of handling Rigid Polyurethane Foam (PUR Foam)

Rigid polyurethane foam (PUR foam) is a thermosetting plastic known for its safe handling and use. The material has several advantages that make it a popular choice in industrial and construction engineering applications. One of the most notable features of rigid PUR foam is its ease of handling. It can be easily cut, shaped and adapted to different applications without the need for advanced equipment or technical skills. This feature makes it ideal for both DIY projects and professional applications.

PUR foam is also known for its low weight in relation to its strength and insulating properties. This makes it easy to transport and install, while providing excellent insulation. It is ideal for insulating walls, ceilings, floors in buildings, as well as pipes and technical installations.

Resilience and Energy Efficiency

An important advantage of rigid PUR foam is its resistance to moisture and mold growth. This feature makes it a reliable choice in wet rooms and other environments where humidity may be a concern. Finally, PUR foam is known for its energy efficiency. It provides excellent thermal insulation, which helps to reduce energy consumption and maintain comfortable temperatures indoors. This makes it a greener choice, as it can help reduce energy consumption and CO2 emissions.

Overall, rigid polyurethane foam is a versatile and reliable material that combines ease of handling, strength, insulation and durability. A favorite in the building and construction industry, it provides effective solutions for a wide range of applications.

Read other related news

Our employees are the foundation

Strong results are created by people who thrive – both professionally and personally. Therefore, employee well-being and proper working conditions are a…

Dan-iso invests in solar panels – A step towards a greener future

2024 was concluded with the installation of solar panels at Dan-iso A/S, and we are happy to be able to take this important step towards a greener future.…

Effective insulation of external heat pumps

When it comes to pipe insulation of outdoor heat pumps, precise temperature conditions and material properties play a crucial role in…

The core of our forging department in Havbro

Our forging department's commitment to quality is not just about producing strong and reliable molds – it also helps reduce material…

Energy optimization in the district heating sector

In a world where energy optimization and sustainable solutions have become our shared responsibility, insulation plays a major role. When we talk about…

Centrifugal Pump Insulation: The Overlooked Key to Efficient Operation

As the industry increasingly focuses on energy efficiency and sustainable solutions, it is no longer enough to just insulate pipes. A…

What is isocyanate – and what role does it play?

Isocyanates are central to the production of PUR and PIR insulation. Get an overview of properties, applications and safety in technical insulation.

What is polyurethane PUR/PIR insulation?

Polyurethane insulation, also known as polyurethane, and colloquially called PUR, is produced by mixing two liquids, polyol and isocyanate. The carefully…

Responsible insulation with a focus on energy savings and operational benefits

Responsible insulation with a focus on energy savings and operational economic benefits

At Dan-iso, we work purposefully with energy-efficient insulation solutions that reduce energy consumption around technical installations. When heating and cooling needs are minimized, it results in lower operating costs – both in the short and long term.

We combine high insulation quality with responsible material management. Our PURrecy program makes it possible to recycle polyurethane foam, thereby reducing waste and resource consumption. Recycling one ton of PUR waste can reduce CO₂ emissions by up to four tons. This not only contributes to a lower environmental impact – it also reduces costs for waste management and raw materials.

By integrating waste from production without compromising on insulation, we create solutions that are both responsible and economically advantageous. This provides a strong foundation for running a business efficiently – with documented results on both the bottom line and climate accounts.

Integrated Responsibility

At Dan-iso, we are deeply committed to environmental responsibility, which is reflected in our PURrecy program. Through this effort, we recycle polyurethane foam (PUR), which both reduces CO2 emissions and reduces waste. By integrating 45% regenerate into our PURrecy products, we maintain a high insulation efficiency. At the same time, we take active responsibility for protecting the environment. Our dedication to sustainability is not just a goal. It is an integral part of everything we do.

Effective CO2 reduction through the recycling of PUR waste

Dan-iso's recycling process provides both environmental and economic benefits. For every tonne of PUR waste that is recycled, CO2 emissions are reduced by up to 4 tonnes. This reduces the company's climate footprint and lowers operating costs. By recycling instead of landfilling or burning waste, you save money on waste management and extraction of new resources. At the same time, the company's sustainability profile is strengthened and opens up financial incentives and support schemes.

Read other related news

Our employees are the foundation

Strong results are created by people who thrive – both professionally and personally. Therefore, employee well-being and proper working conditions are a…

Dan-iso invests in solar panels – A step towards a greener future

2024 was concluded with the installation of solar panels at Dan-iso A/S, and we are happy to be able to take this important step towards a greener future.…

Effective insulation of external heat pumps

When it comes to pipe insulation of outdoor heat pumps, precise temperature conditions and material properties play a crucial role in…

The core of our forging department in Havbro

Our forging department's commitment to quality is not just about producing strong and reliable molds – it also helps reduce material…

Energy optimization in the district heating sector

In a world where energy optimization and sustainable solutions have become our shared responsibility, insulation plays a major role. When we talk about…

Centrifugal Pump Insulation: The Overlooked Key to Efficient Operation

As the industry increasingly focuses on energy efficiency and sustainable solutions, it is no longer enough to just insulate pipes. A…

What is isocyanate – and what role does it play?

Isocyanates are central to the production of PUR and PIR insulation. Get an overview of properties, applications and safety in technical insulation.

What is polyurethane PUR/PIR insulation?

Polyurethane insulation, also known as polyurethane, and colloquially called PUR, is produced by mixing two liquids, polyol and isocyanate. The carefully…

What is technical insulation – and how does it optimize energy?

Hvad er teknisk isolering - og hvordan optimerer det energien?

Technical insulation plays a crucial role in reducing energy losses and improving efficiency in industrial processes and buildings. By minimizing heat loss and protecting pipes, tanks and equipment, technical insulation helps companies save energy, lower operating costs and reduce CO2 emissions. It is therefore an important investment for both the economy and the environment.

Areas of application for technical insulation

Technical insulation is used in many types of installations and systems, such as heating and cooling systems, ventilation ducts, valves, boilers, vessels and HVAC systems. These systems are an integral part of both construction and industrial applications, where proper insulation is necessary to ensure efficient operation. Polyurethane insulation not only protects against energy loss, but also helps maintain the necessary temperatures in the systems, improving their overall efficiency.

The role of polyurethane in technical insulation

Polyurethane (PUR) is an excellent material for technical insulation as it has several functions that can be adapted to specific needs. PUR insulation has excellent thermal properties, which means that it effectively reduces heat loss in systems. It can also be used for both heating and cooling systems as it protects against temperature fluctuations, helping to maintain the desired operating temperature.

Energy efficiency and CO2 reduction through technical insulation

One of the most important benefits of technical insulation is its ability to optimize energy efficiency. By insulating pipes and technical installations with PUR, significant savings in energy consumption can be achieved. Technical insulation helps reduce heat and energy losses, leading to lower operating costs and a lower CO2 footprint. This is especially important in construction and industrial applications, where energy efficiency is a priority for both the economy and the environment.

Reduced operating costs with correct technical insulation

Proper technical insulation with PUR materials can help reduce operating costs by minimizing energy consumption in the systems. PUR and PIR insulation ensures that the systems maintain the right temperature, which means that energy is not wasted due to unnecessary heat loss. This creates a more economic operation, while reducing the need for maintenance and extending the life of the systems.

Improving the indoor climate with technical insulation

In addition to optimizing energy and operating costs, technical insulation plays an important role in creating a healthier indoor climate. Proper insulation of HVAC and heating/cooling systems helps maintain a stable temperature and humidity, which is essential for ensuring a comfortable and healthy environment for residents and employees. Technical insulation with PUR materials effectively reduces the risk of condensation and moisture problems, which can lead to mold growth and other health problems.

Technical insulation and sustainability

Technical insulation also plays a key role in promoting sustainability in construction and industry. By reducing energy consumption and CO2 emissions, proper insulation helps minimize environmental impact. Polyurethane's long-lasting durability and efficient thermal properties make it an ideal choice for those looking to create sustainable solutions while achieving energy savings in their technical systems.

Polyurethane versus glass and mineral wool

While glass and mineral wool are often used to insulate tanks, PUR insulation has a number of advantages:

- Higher insulation capacity per unit thickness: PUR insulation can achieve the same insulation effect with a thinner layer than glass and mineral wool, which saves space and can reduce costs in structures with limited space.

- Better tightness and less sensitivity to moisture: The PUR insulation forms a more cohesive and dense surface, which reduces the risk of moisture penetration and heat loss. Furthermore, fiber-based insulation materials are quite sensitive to moisture, where even small amounts of moisture (5%) can cause a decrease in insulation performance of more than 50%.

- Less risk of sentence: PUR insulation does not tend to settle over time, ensuring stable insulation performance over the entire surface.

Conclusion

Technical insulation is an important process to ensure that systems operate efficiently and economically. By using PUR as an insulation material, building owners and industrial companies can optimize energy efficiency, reduce their carbon footprint and achieve lower operating costs. Technical insulation with PUR not only contributes to maintaining the right temperature in the systems, but also helps to create a healthier indoor climate, making it an important investment in both economy and environment.

Do you want to know more about

If you would like further independent information about polyurethane insulation, we refer you to:

- https://plast.dk/plast-i-byggeriet/fakta-om-pur-isolering/

- https://www.bolius.dk/isolering-faa-det-store-overblik-98118#:~:text=Polyurethan%20og%20polyisocyanurat%20(PUR%20og%20PIR)%C2%A0

- https://iopscience.iop.org/article/10.1088/1757-899X/570/1/012029/pdf

- https://belglas.com/wp-content/uploads/2015/11/abschlussbericht_-zustandsaenderungen-von-mineralwolle.pdf

Read other related news

Our employees are the foundation

Strong results are created by people who thrive – both professionally and personally. Therefore, employee well-being and proper working conditions are a…

Dan-iso invests in solar panels – A step towards a greener future

2024 was concluded with the installation of solar panels at Dan-iso A/S, and we are happy to be able to take this important step towards a greener future.…

Effective insulation of external heat pumps

When it comes to pipe insulation of outdoor heat pumps, precise temperature conditions and material properties play a crucial role in…

The core of our forging department in Havbro

Our forging department's commitment to quality is not just about producing strong and reliable molds – it also helps reduce material…

Energy optimization in the district heating sector

In a world where energy optimization and sustainable solutions have become our shared responsibility, insulation plays a major role. When we talk about…

Centrifugal Pump Insulation: The Overlooked Key to Efficient Operation

As the industry increasingly focuses on energy efficiency and sustainable solutions, it is no longer enough to just insulate pipes. A…

What is isocyanate – and what role does it play?

Isocyanates are central to the production of PUR and PIR insulation. Get an overview of properties, applications and safety in technical insulation.

What is polyurethane PUR/PIR insulation?

Polyurethane insulation, also known as polyurethane, and colloquially called PUR, is produced by mixing two liquids, polyol and isocyanate. The carefully…

What is isocyanate – and what role does it play?

What is isocyanate?

Isocyanate: A key element in modern materials and industry

Isocyanate is a chemical that plays a central role in many industrial processes, especially in the production of polyurethanes and other polymers. It is an important raw material used in everything from construction to the automotive industry and furniture production. Although isocyanate is extremely useful, it requires caution when handling due to its potential health risks. This article delves into what isocyanate is, how it is used, and the safety precautions that should be taken when using it.

What is isocyanate?

Isocyanate is a group of chemical compounds that have an -NCO group (a reactive group consisting of a nitrogen atom bonded to a carbonyl atom). This structure enables isocyanates to react with a wide range of chemicals, particularly alcohols, creating polyurethanes – one of the most versatile and widely used materials in modern industry.

Isocyanates can be divided into different types depending on their chemical composition, such as MDI (methylene diphenyl isocyanate) and TDI (toluene diisocyanate). Both types are primary components in the production of polyurethane, which is used in a wide range of products, from insulation materials to foams and coatings.

The use of isocyanates in industry

1. Polyurethane production:

Isocyanate is primarily known for its use in the production of polyurethane, which is an extremely versatile material. Polyurethane is used in foam products (such as mattresses, insulation materials and car seats), coatings (such as paints and varnishes), elastomers (such as in tires and sealants) and in the form of solid materials (such as in furniture and building materials).

2. Building and insulation materials:

Isocyanate-based polyurethane foams are often used for thermal and acoustic insulation in buildings. These foam products offer excellent thermal insulation and are lighter than many alternative materials, making them popular in construction and renovation. They are also used in pipe insulation where efficiency and durability are essential.

3. Automotive industry and furniture production:

Polyurethane is widely used in the automotive industry to make components such as seats, dashboards and shock absorbers. The material is lightweight, strong and can be molded into precise shapes, making it ideal for these applications. Similarly, polyurethane is used in the furniture industry to create comfortable and durable foam products for upholstery.

Safety and health risks

Although isocyanate is a highly useful substance, it is also potentially dangerous if not handled properly. Isocyanate fumes are highly irritating to the respiratory tract and can cause serious health problems, including asthma, allergic reactions and, in rare cases, chronic lung disease. In addition, skin contact can cause irritation or allergic reactions. See the work with polyurethane.

Therefore, it is important to take the right safety precautions when working with isocyanates. This includes the use of personal protective equipment such as respirators, gloves and goggles, as well as good ventilation in work areas. Workers should also be aware of the safety regulations and relevant warnings associated with the chemical, and regular health monitoring is necessary in industrial environments where isocyanates are handled.

Future perspectives and sustainability

With an increasing focus on sustainability and environmentally friendly materials, research is underway to develop new types of isocyanate-based products that are less harmful to both health and the environment. There is also a growing need to find alternatives to traditional polyurethanes, which are based on fossil fuels. In this regard, opportunities are being explored to use bio-based isocyanates and reduce the toxic effects of certain compounds.

Conclusion

Isocyanate is an indispensable component in many modern materials and industrial processes, especially when it comes to the production of polyurethane. From insulation in buildings to automotive components and furniture production, it is a versatile substance that helps create efficient and durable solutions. Despite its many benefits, it is crucial to take the necessary precautions when handling isocyanate to protect both health and safety. Future research will likely focus on making isocyanate-based products more sustainable and less harmful to both people and the environment.

Danish legislation and requirements for working with isocyanate

In Denmark, work with isocyanates is regulated by several laws and directives. Isocyanates are classified as hazardous substances. Employers must follow the Danish Working Environment Authority's guidelines, which contain safety requirements. This includes the use of respiratory protection, gloves and protective glasses. There must also be sufficient ventilation in the work areas. Employees must be trained in the risks and safety measures.

Safety data sheets

Safety data sheets (SDS) are necessary for handling chemicals such as isocyanates. They contain important information about hazards and handling. Employers must provide safety data sheets to employees. They help to make informed decisions about protection against risks.

EU legislation

Denmark is part of REACH Regulation. This EU legislation protects people and the environment from dangerous chemicals. REACH requires chemicals such as isocyanates to be registered with ECHA. Companies must document the safety of substances and assess risks. They must ensure that substances do not pose a hazard. REACH can lead to restrictions or bans on dangerous substances.

Overall, working with isocyanates is strictly regulated in Denmark and the EU. Both employers and employees must follow safety measures to minimize the risk.

Read other related news

Our employees are the foundation

Strong results are created by people who thrive – both professionally and personally. Therefore, employee well-being and proper working conditions are a…

Dan-iso invests in solar panels – A step towards a greener future

2024 was concluded with the installation of solar panels at Dan-iso A/S, and we are happy to be able to take this important step towards a greener future.…

Effective insulation of external heat pumps

When it comes to pipe insulation of outdoor heat pumps, precise temperature conditions and material properties play a crucial role in…

The core of our forging department in Havbro

Our forging department's commitment to quality is not just about producing strong and reliable molds – it also helps reduce material…

Energy optimization in the district heating sector

In a world where energy optimization and sustainable solutions have become our shared responsibility, insulation plays a major role. When we talk about…

Centrifugal Pump Insulation: The Overlooked Key to Efficient Operation

As the industry increasingly focuses on energy efficiency and sustainable solutions, it is no longer enough to just insulate pipes. A…

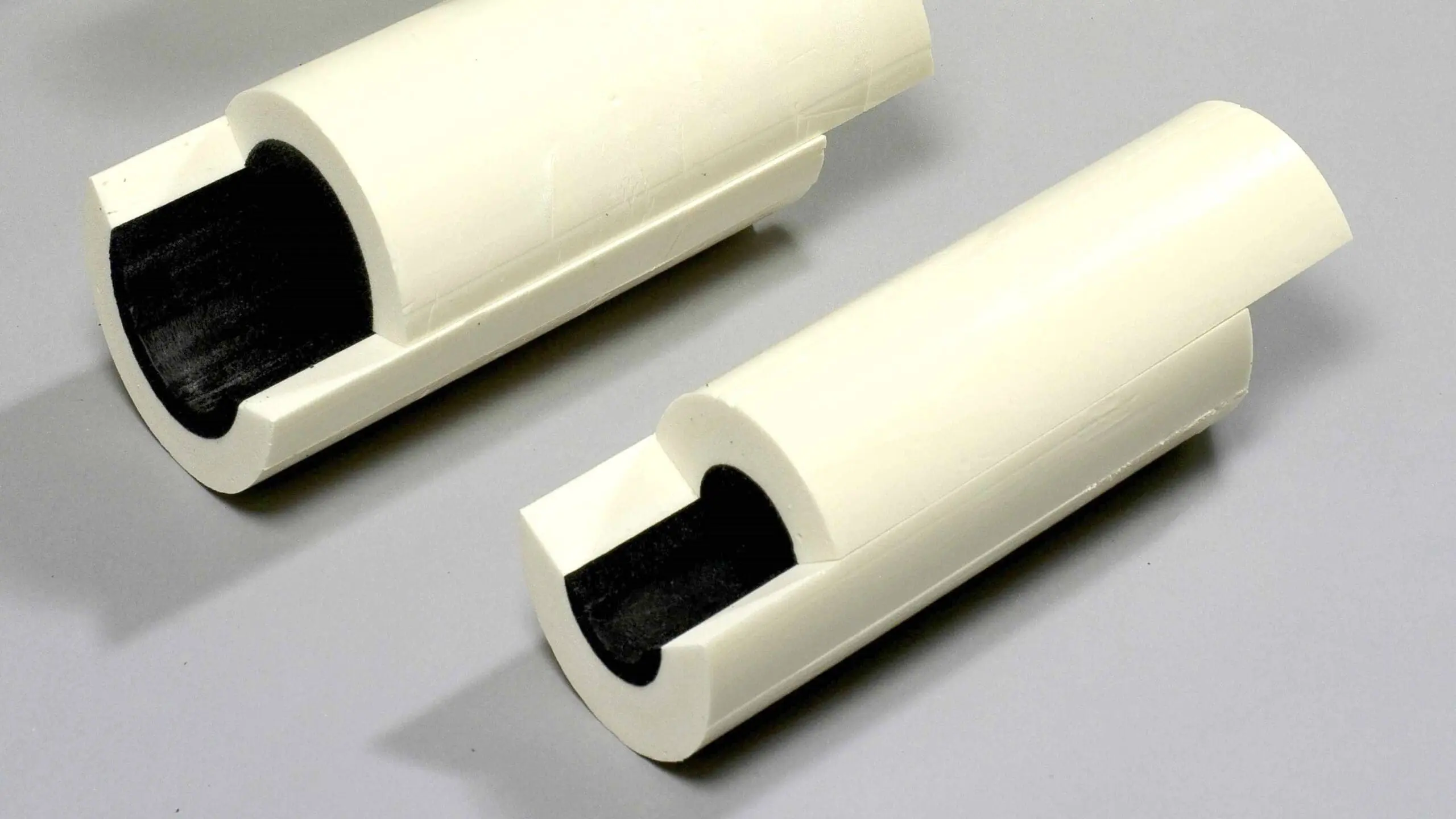

What is polyurethane PUR/PIR insulation?

Polyurethane insulation – commonly known as PUR, is produced by mixing two liquids, polyol and isocyanate. The carefully calculated reaction process that starts when the two liquids are mixed is called foaming. The result of the process is a viscous, foaming molding compound that quickly forms PUR in solid form. PUR can be produced with different stiffness and density.

Dan-iso offers insulation solutions based on polyurethane in the form of molded tube shells and custom-made parts milled from foam blocks with our 5-axis CNC. PIR block foam (polyisocyanurate) is a modified PUR system. PIR Block Foam is distinguished by its relatively low flammability and its resistance to higher temperatures. Dan-iso PIR block foam meets the “Euroclass E” fire test (EN-ISO 11925-2).

Casting of pipe bowls

The expertise lies in knowing all the variation possibilities, in order to get the best out of the material. Dan-iso has more than 30 years of experience to build on when it comes to casting pipe shells.

Rigid PUR is one of the most effective insulation materials available. The insulation value is over 30 % better than stone wool, mineral wool and EPS insulation.

What is PUR pipe insulation used for?

How is PUR and PIR Pipe Insulation Made?

Dan-iso offers technical insulation based on polyurethane in the form of pipe shells and custom-made parts. The pipe shells are used to insulate pipes and prevent heat loss. Our custom-made solutions are created using CNC technology, which makes it possible to produce precise and customized insulation materials from large PUR and PIR foam blocks. This technology ensures high precision and effective solutions for technical insulation.

PIR (polyisocyanurate) is a modified version of PUR, where the chemical composition of the material has been changed to improve certain properties. PIR pipe insulation differs from PUR by having a lower flammability and a higher resistance to heat. This makes PIR a better choice in situations where fire resistance and temperature control are required. PUR and PIR pipe insulation are both used in technical insulation, but PIR is more often chosen for applications where fire resistance is an important requirement.

The insulation properties of PUR and PIR

Both PUR and PIR are known for their excellent thermal insulation properties. They have low thermal conductivity, which means they effectively retain heat inside systems and prevent heat loss. This makes them ideal for use in both construction and industry, where it is important to maintain a stable temperature in pipelines, HVAC systems and other heat-sensitive applications. In addition, both PUR and PIR have high mechanical strength, making them resistant to physical stress.

PIR pipe insulation is known for its improved fire resistance compared to PUR. This makes it a popular choice in situations where fire safety is a priority, such as in buildings and industrial installations. PIR meets more stringent fire test requirements and often achieves the fire classification “Euroclass E”, which means it has a lower flammability and reduces the risk of fire spreading. This is an important property in areas where the insulation needs to protect against high temperatures and fire hazards.

Areas of application and benefits of PUR and PIR pipe insulation

PUR and PIR pipe insulation is used in a wide range of technical and industrial applications. Both materials are used for pipe insulation in construction and industrial production, where it is necessary to prevent heat loss and ensure efficient energy use. PUR and PIR pipe shells are also commonly used in HVAC systems, heating installations and pipelines transporting hot or cold fluids. They help to maintain the desired temperature constant, minimizing energy consumption.

In industrial applications, it is crucial to choose insulation materials that are both efficient and durable. PUR and PIR pipe insulation offer a good balance between thermal efficiency and mechanical strength, making them ideal for withstanding the demands of industrial environments. Both materials contribute to maintaining a stable climate, reducing energy consumption and minimizing operating costs in industrial facilities, making them an effective choice for long-term solutions.

Advantages of polyurethane insulation

Effective insulation and durability

PUR (polyurethane foam) has a high insulating capacity, which makes it effective for both heat and cold insulation. It ensures energy savings and lower costs with its low thermal conductivity. PUR is ideal for insulating buildings, pipes and technical installations where effective thermal insulation is required. The material also has a high strength-to-weight ratio, which makes it both strong and light. PUR is robust, durable and easy to handle and install.

PUR does not absorb moisture, preventing damage from water absorption and maintaining strength. It is perfect for use in humid environments as it does not lose its insulating properties. The material is also temperature stable and works effectively at both high and low temperatures, ensuring long-lasting performance even in extreme conditions.

Stability and chemical resistance

PUR is torsionally stable and retains its shape under load. It resists deformation and ensures long-term durability, even in harsh conditions. The material is therefore ideal for structures where stability is important.

In addition, PUR is chemically resistant and resists attack from many chemicals and solvents. It retains its properties even in challenging environments, making it ideal for use in industries where chemicals may be present. PUR ensures durability and longevity when exposed to chemical agents.

Recycling polyurethane insulation

Polyurethane and thermoset plastic

Polyurethane insulation is a thermosetting plastic, also known as a thermosetting plastic or curable plastic. This type of plastic has the characteristic property that it can harden or solidify irreversibly through a chemical reaction. For polyurethane, this hardening occurs when the two components, isocyanate and polyol, are mixed together. When they are mixed, a rigid foam is formed, which causes the plastic to solidify. Once a thermosetting plastic has hardened, it cannot be reheated or melted to a liquid state, which distinguishes it from thermoplastic materials.

Properties and recycling

Curing plasters are often used in a number of applications where it is important to achieve great strength, resistance to chemicals and temperature stability. This stability makes polyurethane particularly suitable for insulating technical installations under demanding conditions. The high resistance to both temperature and chemicals is a great advantage in industrial environments. However, the same stability means that it is difficult to reuse polyurethane foam. Unlike thermoplastic materials, which can be melted and reshaped, thermosetting plastics cannot be recycled in the same way.

Dan-iso was the first in the world to develop a method for mechanical recycling of rigid polyurethane foam. This method makes it possible to recycle up to 45% of the material in new products, which is a pioneering step towards a more sustainable and economical use of polyurethane.

Read other related news

Our employees are the foundation

Strong results are created by people who thrive – both professionally and personally. Therefore, employee well-being and proper working conditions are a…

Unimaginable special solutions and possibilities in PUR and PIR

The Cimbrer bull stands at the entrance to Friis Shoppingcenter Streetfood in Aalborg. We are thrilled to have contributed to 'shaping'…

Dan-iso invests in solar panels – A step towards a greener future

2024 was concluded with the installation of solar panels at Dan-iso A/S, and we are happy to be able to take this important step towards a greener future.…

Effective insulation of external heat pumps

When it comes to pipe insulation of outdoor heat pumps, precise temperature conditions and material properties play a crucial role in…

The core of our forging department in Havbro

Our forging department's commitment to quality is not just about producing strong and reliable molds – it also helps reduce material…

Energy optimization in the district heating sector

In a world where energy optimization and sustainable solutions have become our shared responsibility, insulation plays a major role. When we talk about…