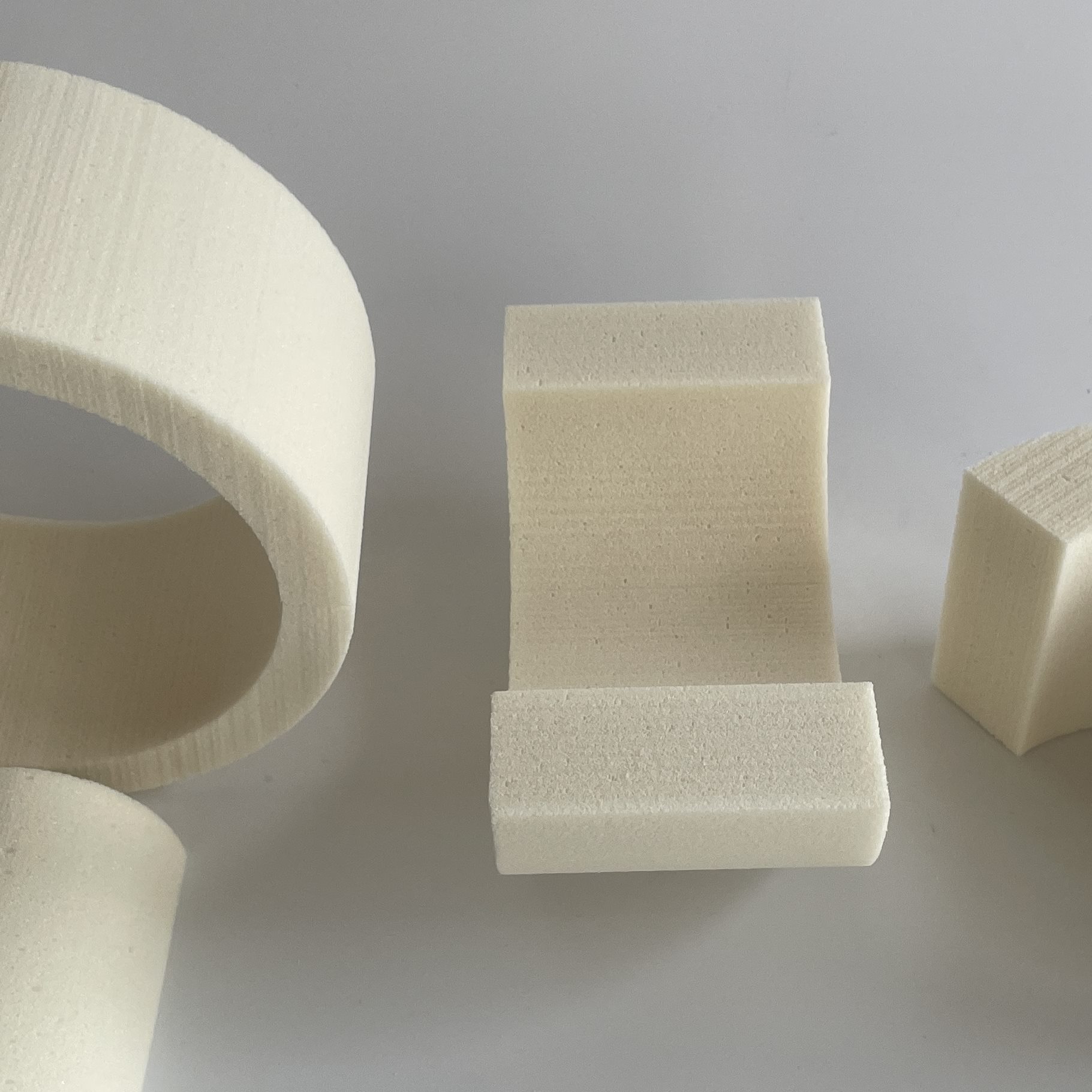

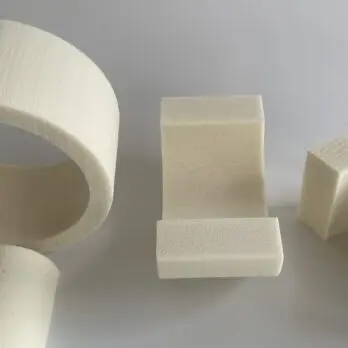

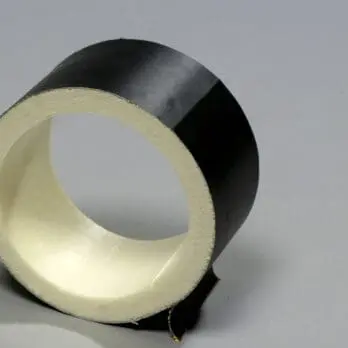

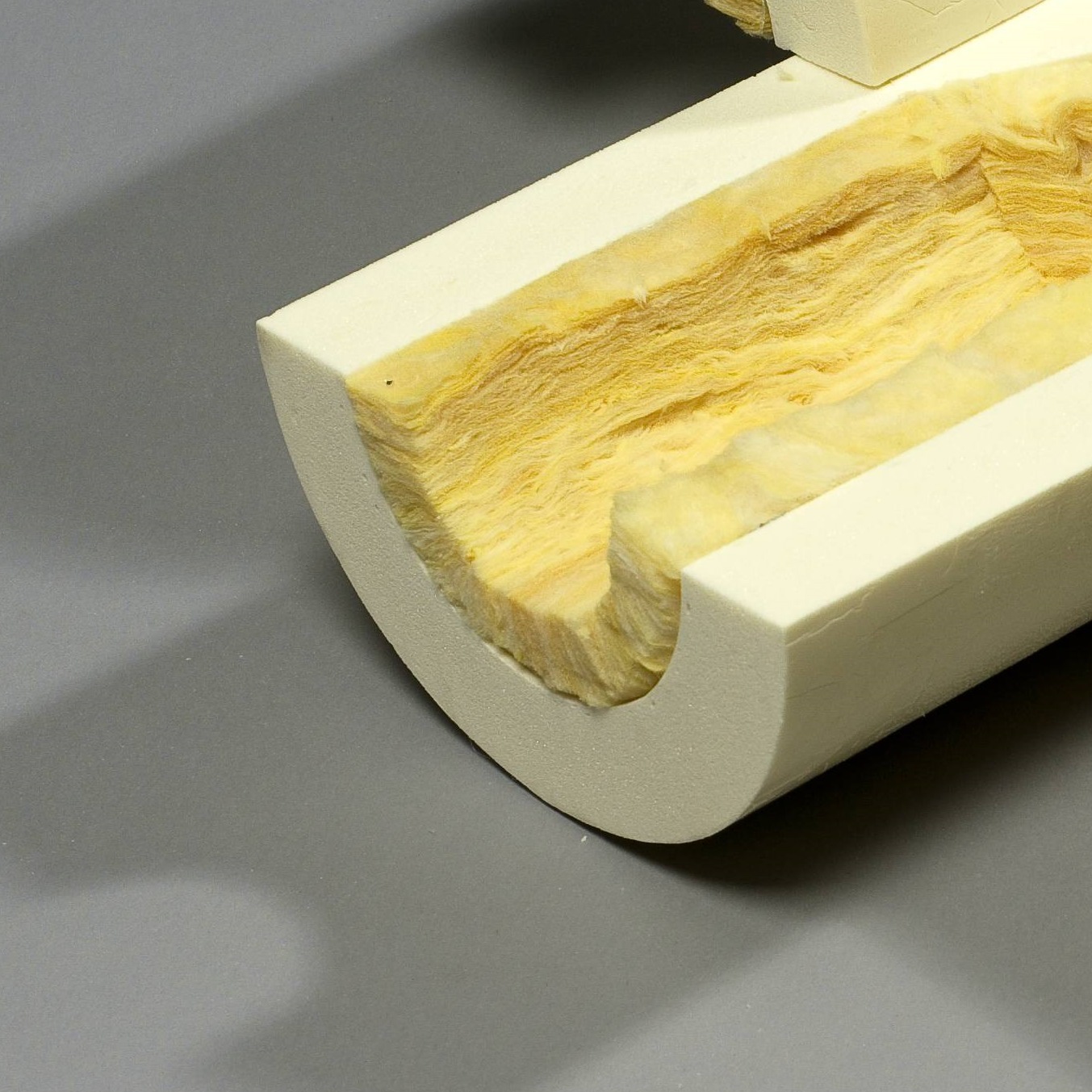

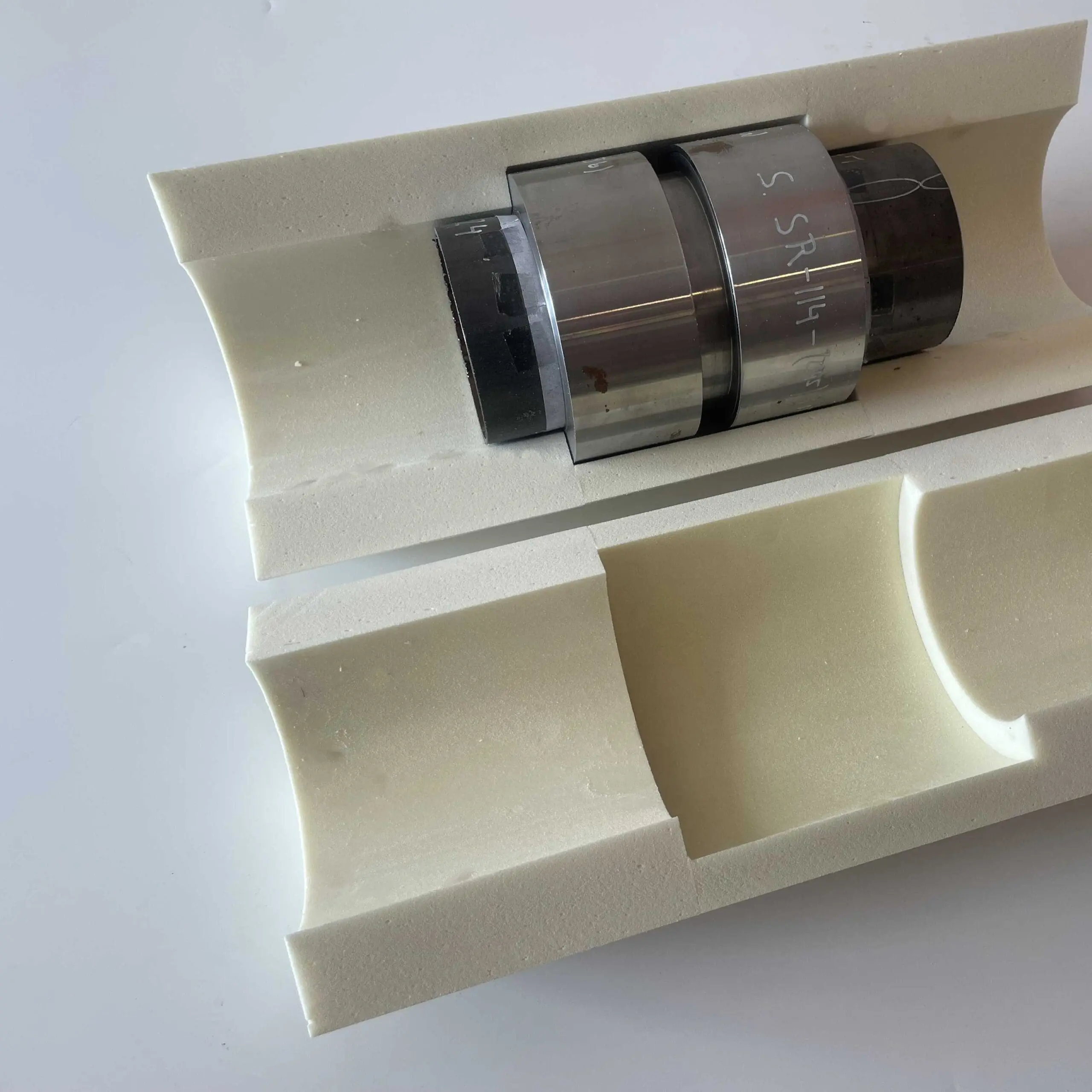

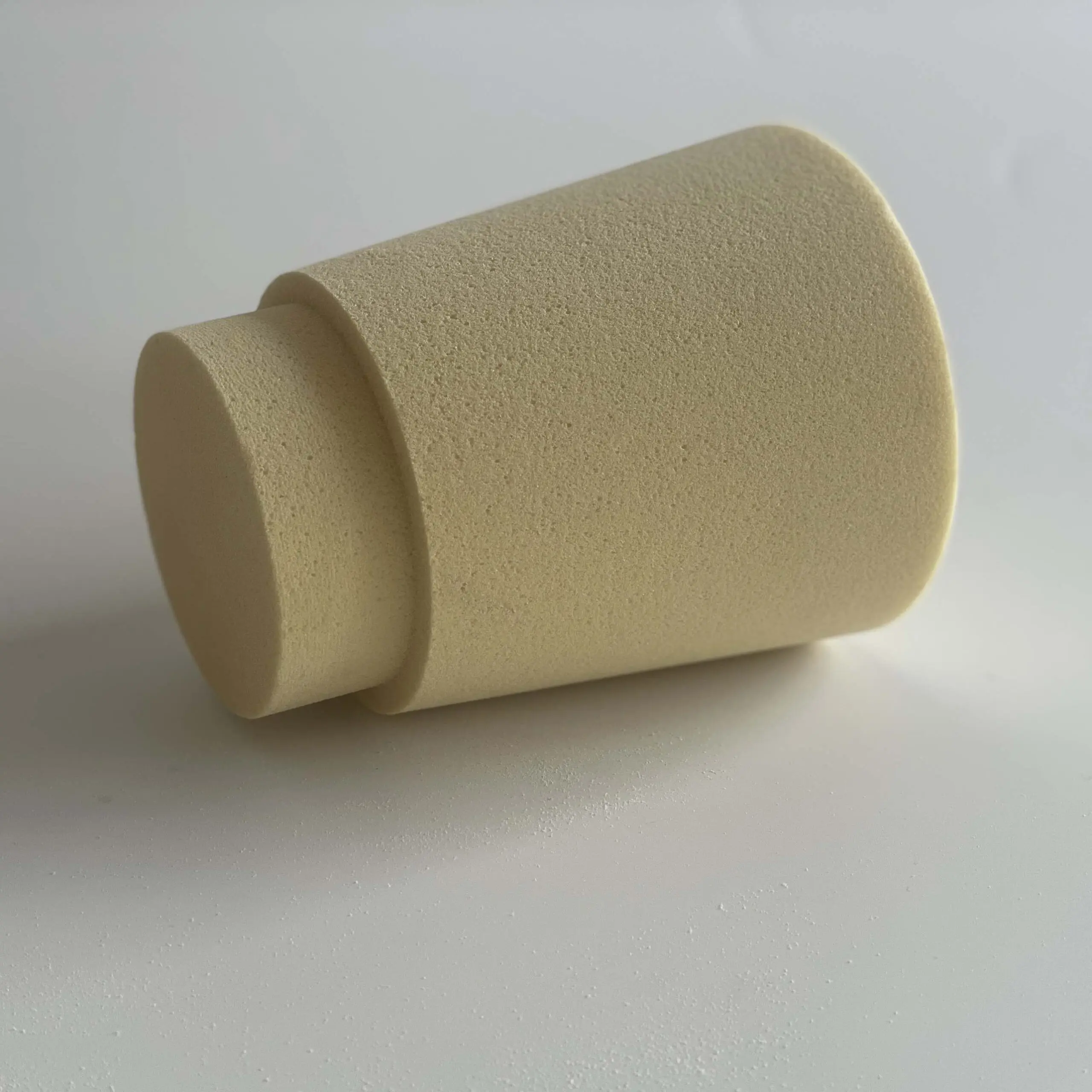

Polyurethane suspension bowls

Effective vibration and shock absorption

Explore our selection of polyurethane suspension cups and tube supports, ideal for effective vibration and shock absorption.

They are perfect for supporting and stabilizing pipes, with durability and corrosion protection. Explore our selection of polyurethane suspension cups and tube supports, ideal for effective vibration and shock absorption.

Suspension cups, also known as pipe supports, are essential components in industrial insulation, where high compressive strength and load-bearing capacity are required. Dan-isoBASE bearings and suspension cups, manufactured in PUR or PIR and designed to provide reliable support and durability in demanding environments.

Note: Supplied as standard without surface coating - can be coated by further agreement.

Application

Suspension bowls and pipe supports are essential components in industrial insulation, where high compressive strength and bearing capacity are required.

Here are some of their primary uses:

Technical data sheet

Download product sheet.

Technical specifications

| Material properties | Value | Standard |

|---|---|---|

| Density (Mean) | 75 kg/m3 | ISO 845 (/DIN 53420-78) |

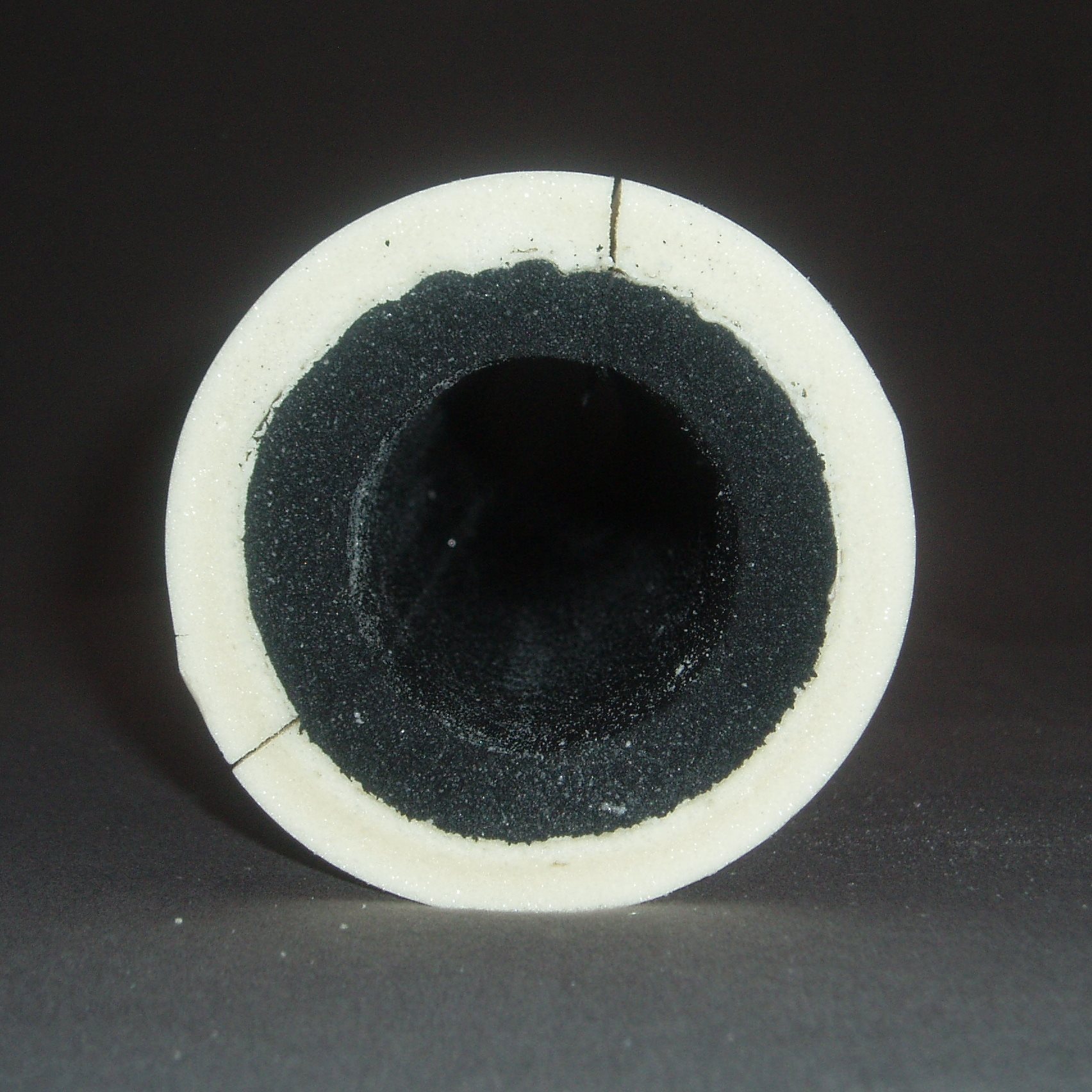

| Closed cells | > 88% | ISO 4590 |

| Cell size | < 0.5 mm | EN253 5.3.2.1 |

| Water absorption during boiling | Mean 4.4% Vol | EN253 5.3.5 |

| Compressive strength, radial | ≥ 0.40 Mpa | ISO 844 |

| E-Module, radial | ≥ 9.5 MPa | ISO 844 |

| Dimensional stability | ||

| -30°C | 48h: 0.0 % vol. | |

| +100°C | 48h: -1.0 % vol. | (ISO 2796 / DIN 53431-77) |

| +150°C | 48h: -1.4 % vol. | |

| Thermal conductivity | ||

| λ10 | 0.0238 W/m*K | |

| λ20 | 0.0247 W/m*K | ISO 8301 / ASTM C518 |

| λ50 | 0.0284 W/m*K | |

| Fire class | B3 | DIN 4102 Part 1 |