Segmented and milled bends for optimal pipe insulation

Solutions that ensure optimal insulation and reduce heat loss

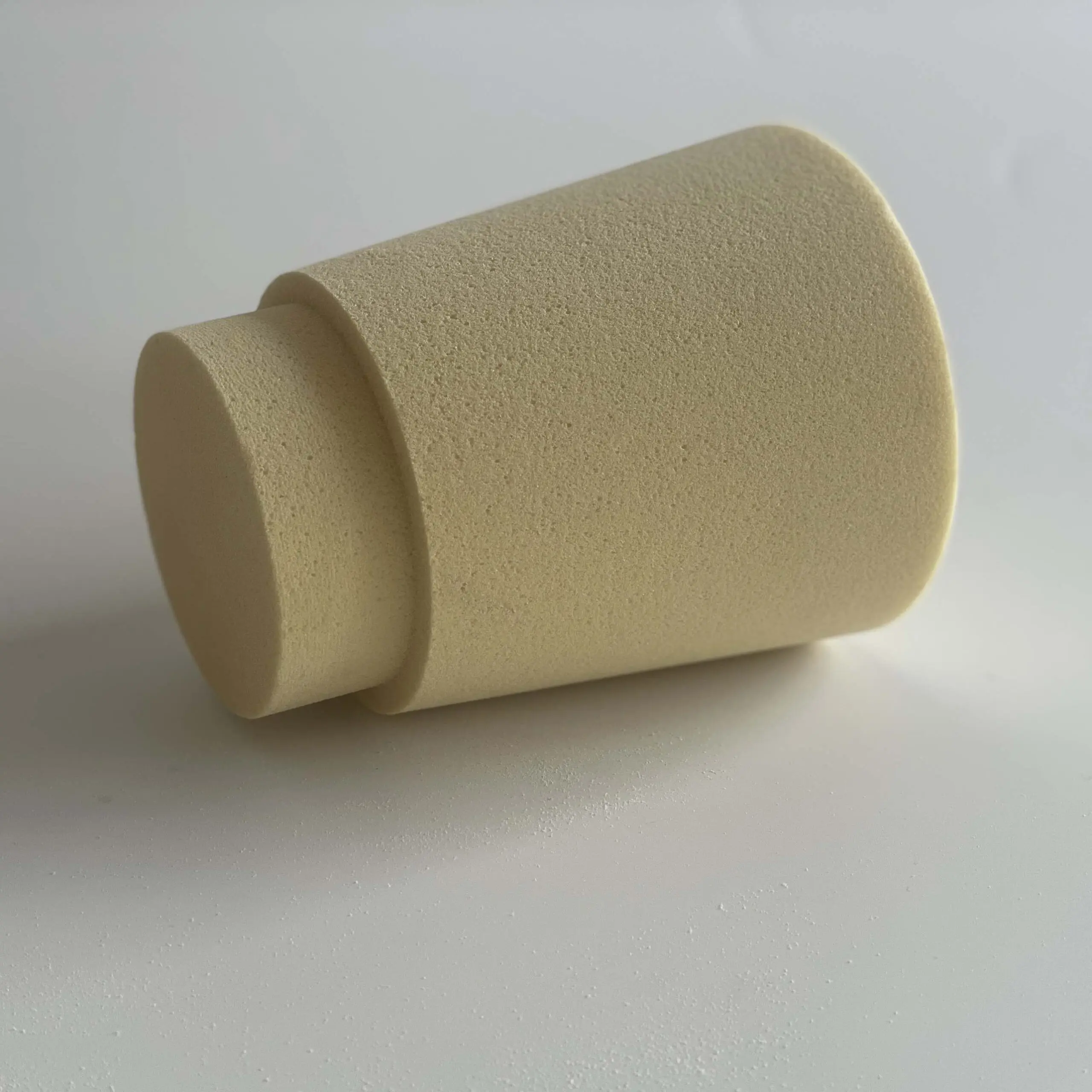

Our PUR and PIR bends for technical insulation are available in two effective variants: segment bends and milled bends, made of quality PUR or PIR. Regardless of your needs, we offer solutions that ensure optimal insulation and reduce heat loss.

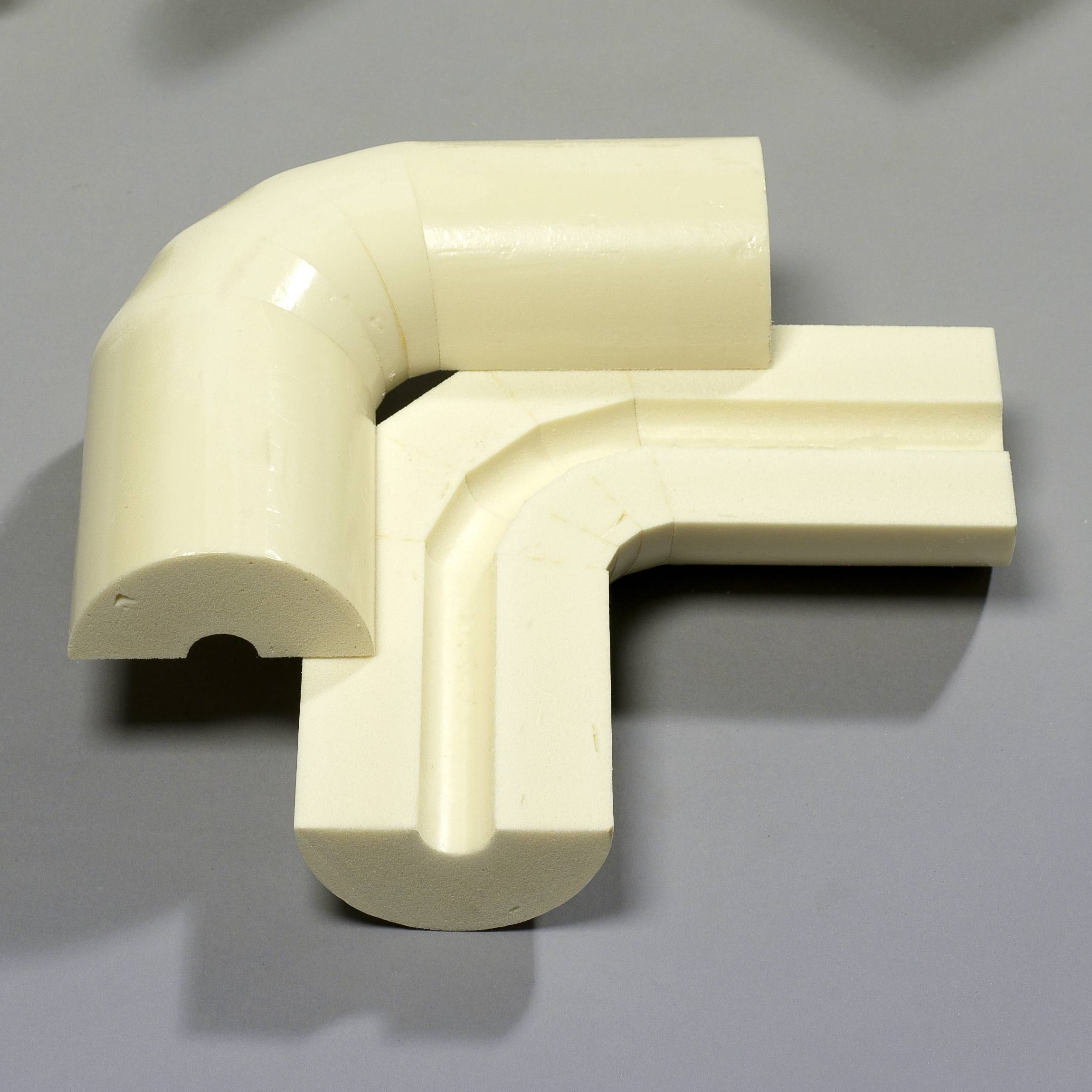

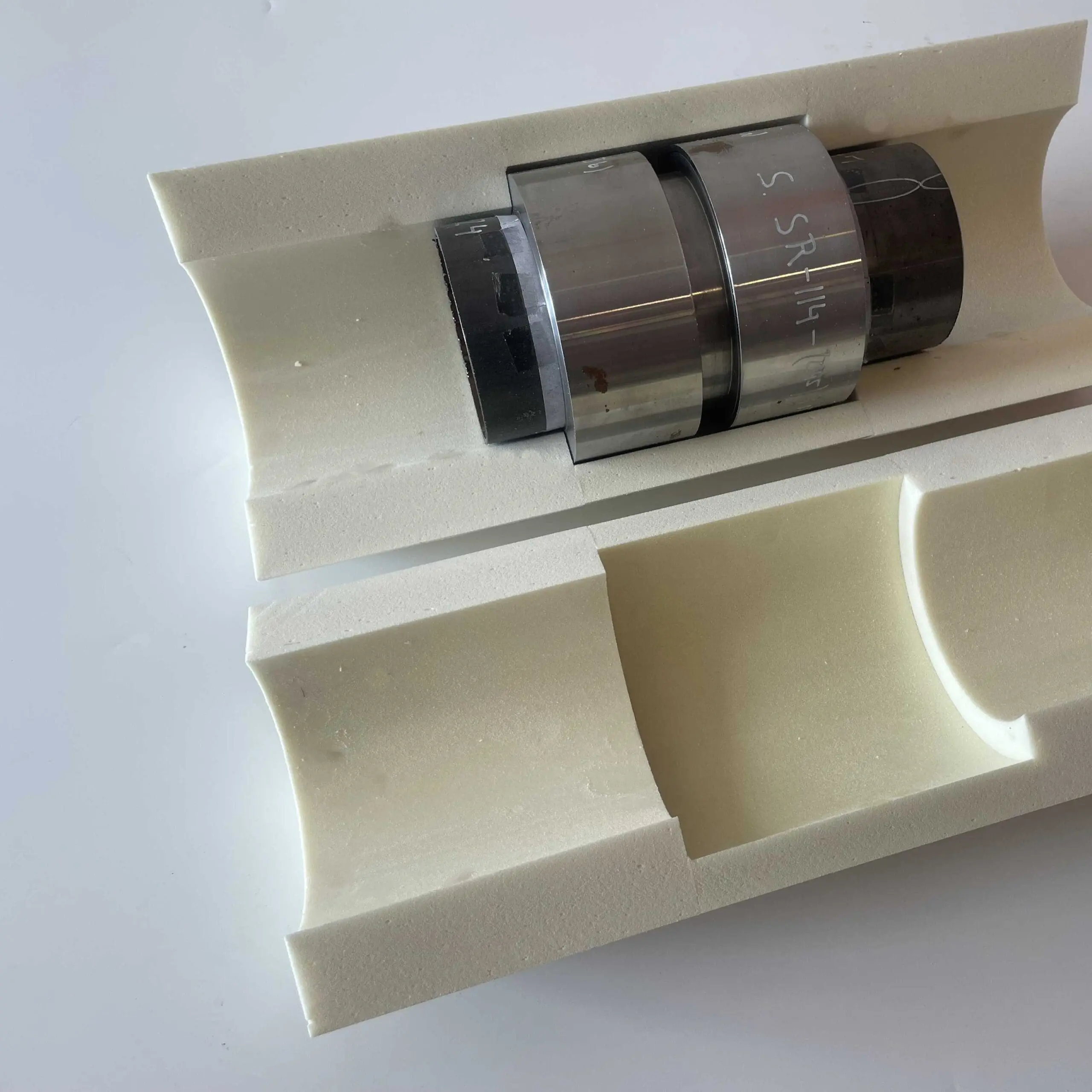

Segment bends

These bends are made by cutting molded bowls into segments which are then glued together. Segment bends are available in degrees 15, 30, 45 and 90. They can be supplied in dimensions from Ø77 mm to Ø630 mm for steel pipes and Ø90 mm to Ø315 mm for aluminum pipes.

They are ideal for projects where flexibility and adaptability are needed, such as in industrial pipe installations and large construction or renovation projects.

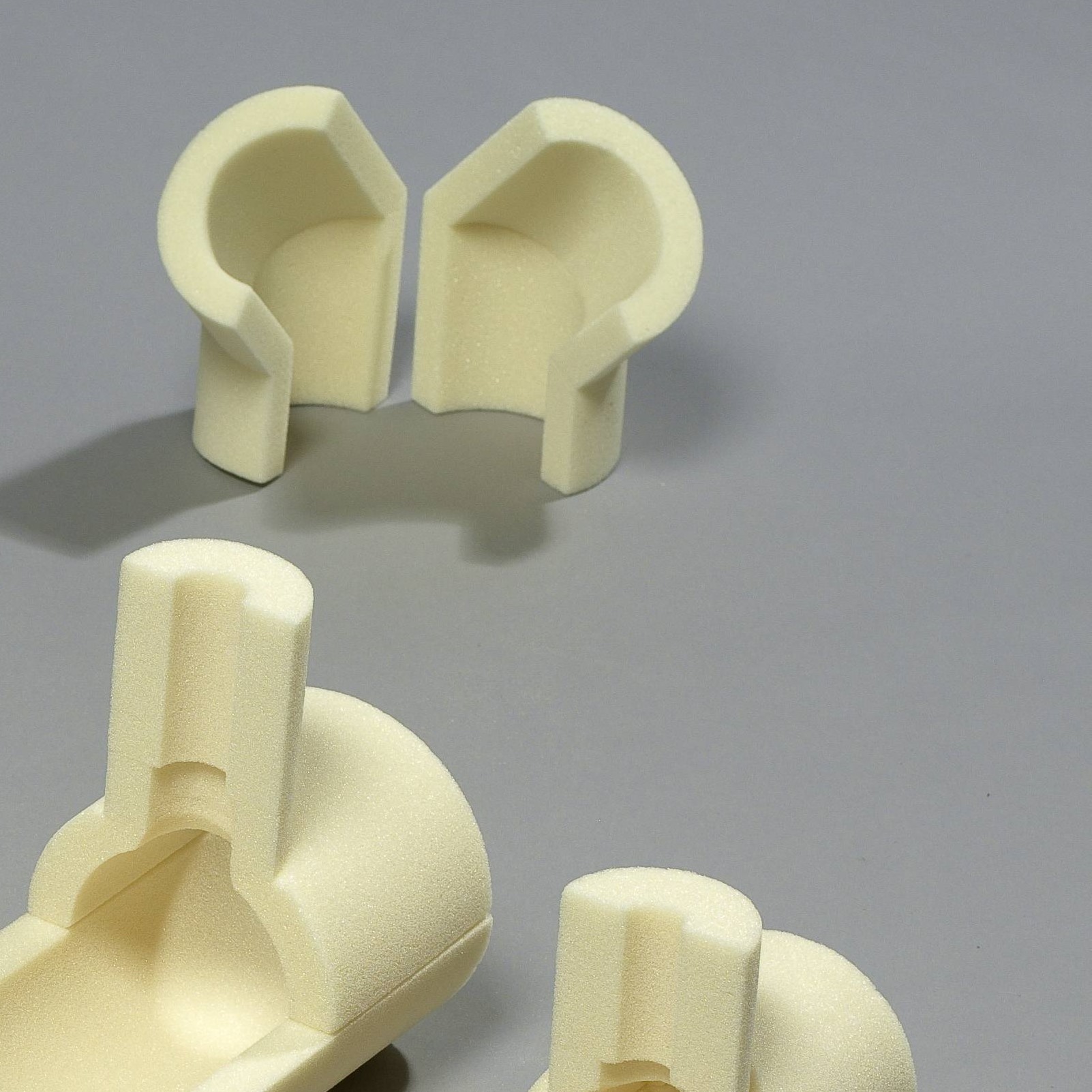

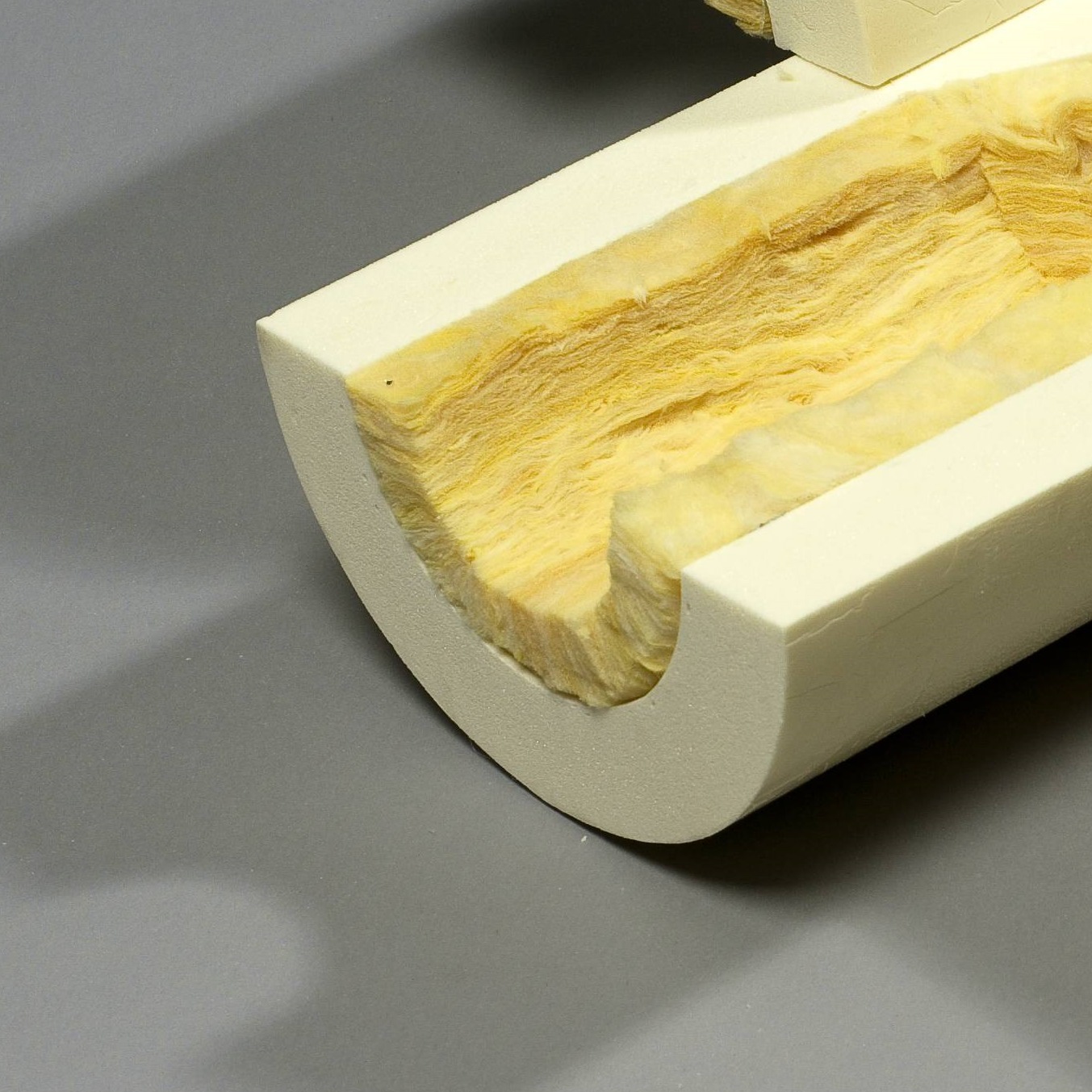

Milled bends

These bends are cut directly from foam blocks, which minimizes the number of joints and thus significantly reduces heat loss.

Milled bends are perfect for applications where maximum insulation efficiency is critical, such as in high-efficiency HVAC systems and refrigeration plants.

Both types of bends can be customized precisely to your specifications, making them ideal for both large industrial installations and more specialized engineering projects.

Application

Ideal Insulation solutions with PUR Bends and T-pieces

PUR bends and T-pieces are the ideal insulation solution for large industrial pipe installations, construction and renovation projects as well as specialized technical projects. Thanks to their flexible design and excellent thermal insulation properties, they protect pipes against temperature fluctuations, prevent energy loss and ensure correct operation in a multitude of applications.

Flexible, durable and energy-efficient solutions for industrial and technical pipe installations

The PUR (polyurethane) material is both light and strong, while being resistant to mechanical stress and extreme temperatures. This makes PUR bends and tees the perfect choice for both indoor and outdoor pipe installations. Their tight fit prevents heat loss, increasing energy efficiency, while providing optimal protection in both new installations and existing systems that require upgrading.

These solutions are used in many sectors, including the oil and gas industry, construction, HVAC systems and refrigeration installations, and their versatility makes them a preferred solution in specialized engineering projects where precision and durability are essential to achieve the best results.

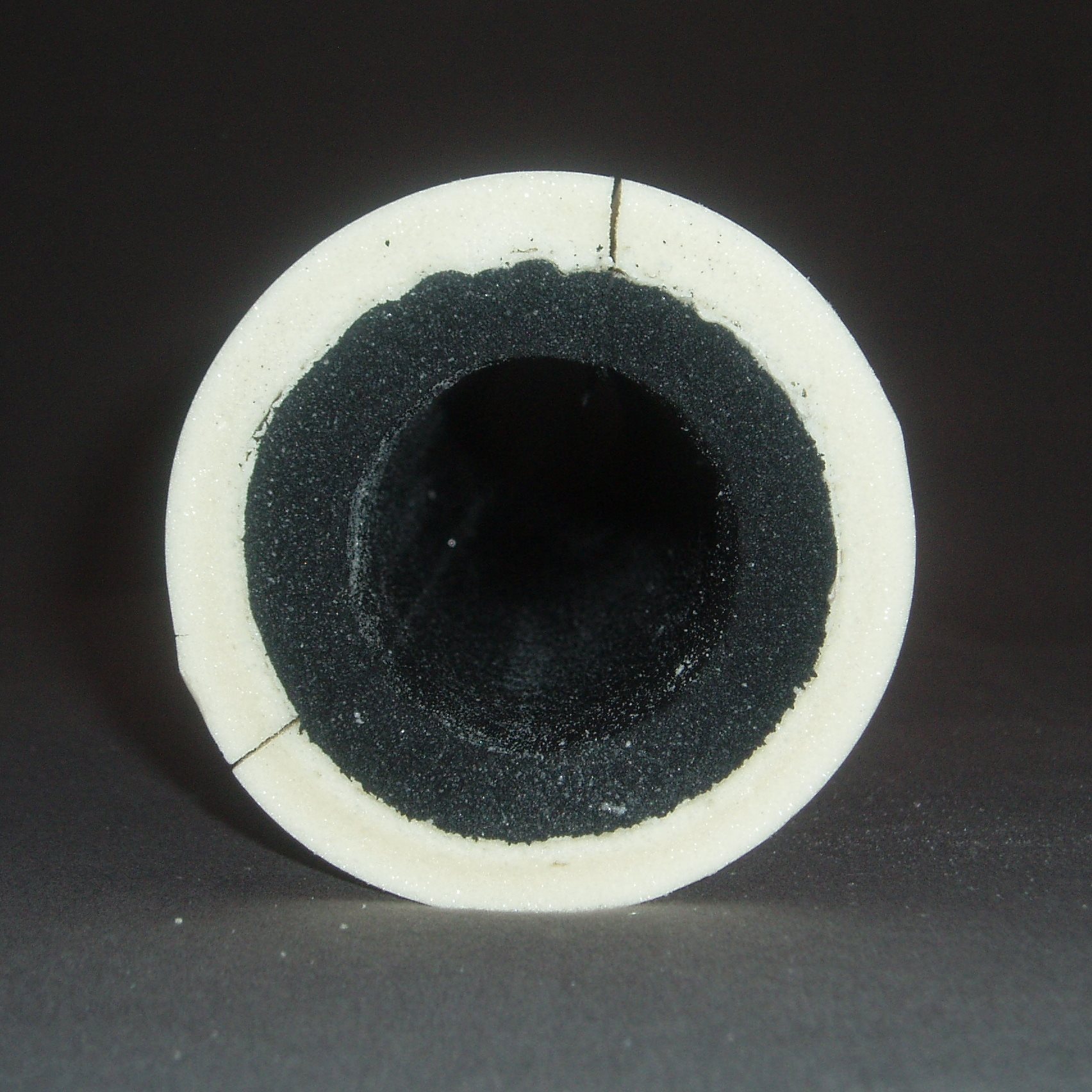

Also explore our Dan-isoMOLD pipe insulation with internal foam protection – Dan-isoMOLD with foam.

Technical data sheet

Contact us for product sheet.

Technical specifications

| Material properties | Value | Standard |

|---|---|---|

| Density | 68 kg/m3 (±8 kg/m3) | ISO 845 (/DIN 53420-78) |

| Closed cells | ≥ 88 % | ISO 4590 |

| Cell size | < 0.5 mm | EN253 5.3.2.1 |

| Water absorption during boiling | Mean value 4.4 % Vol | EN253 5.3.5 |

| Compressive strength, radial | ≥ 0.40 Mpa | ISO 844 |

| E-module, radial | ≥ 9.5 MPa | ISO 844 |

| Dimensional stability | ||

| -30 C° | 48h: 0.0 % vol | |

| +100 C° | 48h: -1.0 % vol | ISO 2796 (/DIN 53431-77) |

| +150 C° | 48h: -1.4 % vol | |

| Thermal Insulation Value (thermal conductivity) | ||

| λ10 | 0.0238 W/m*K | |

| λ20 | 0.0247 W/m*K | ISO 8301 / ASTM C518 |

| λ50 | 0.0284 W/m*K | |

| Fire class | B3 (Normal combustible) | DIN 4102 Part 1 |