Optimal insulation for the food and pharmaceutical industry

In accordance with EU Directive 2011/10/EC

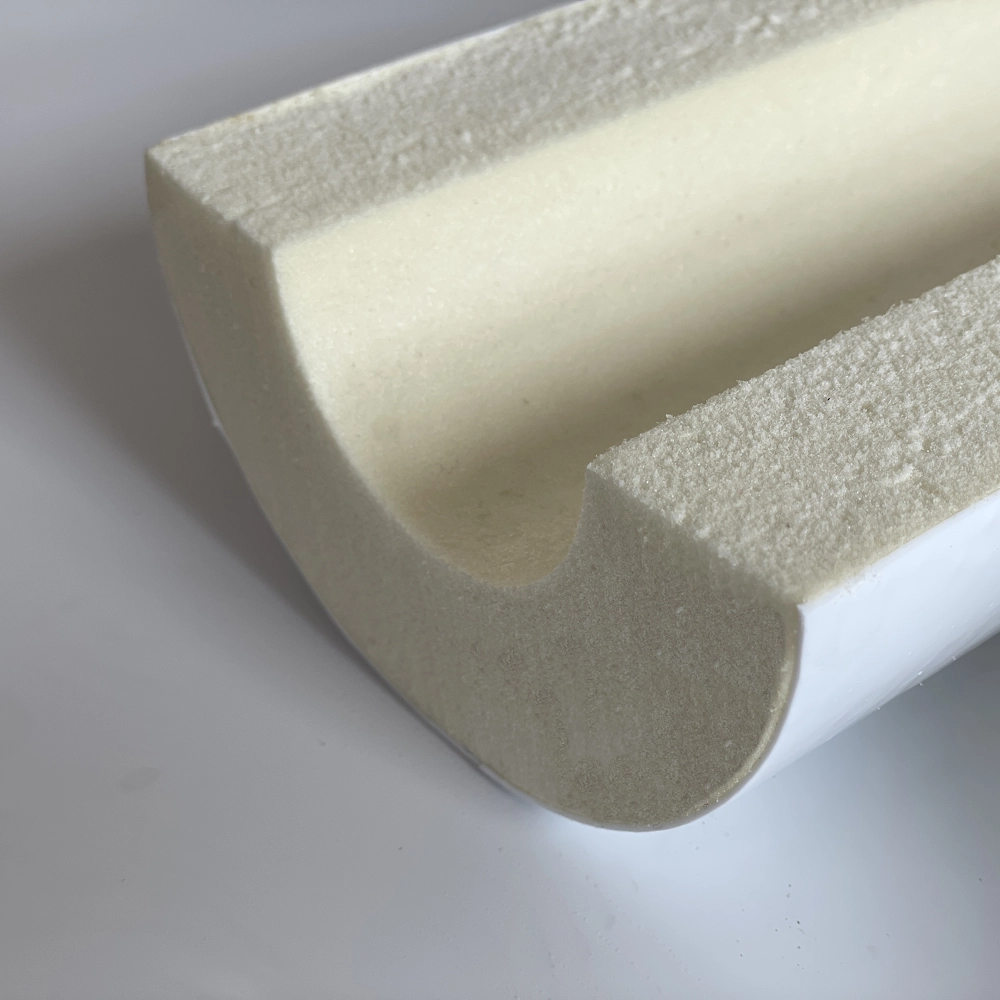

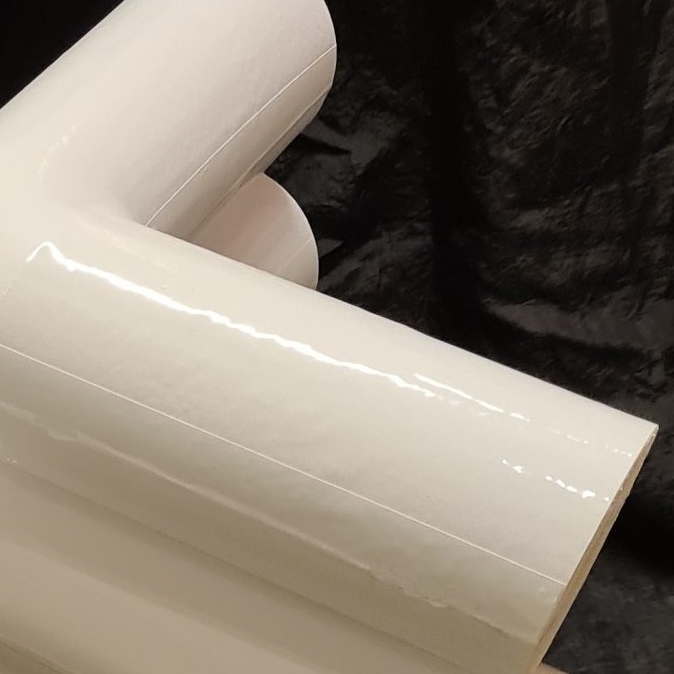

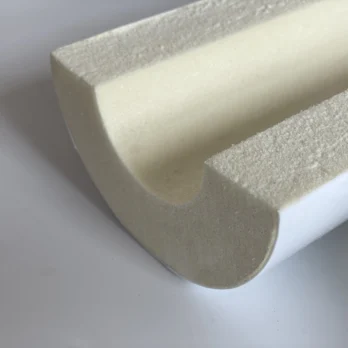

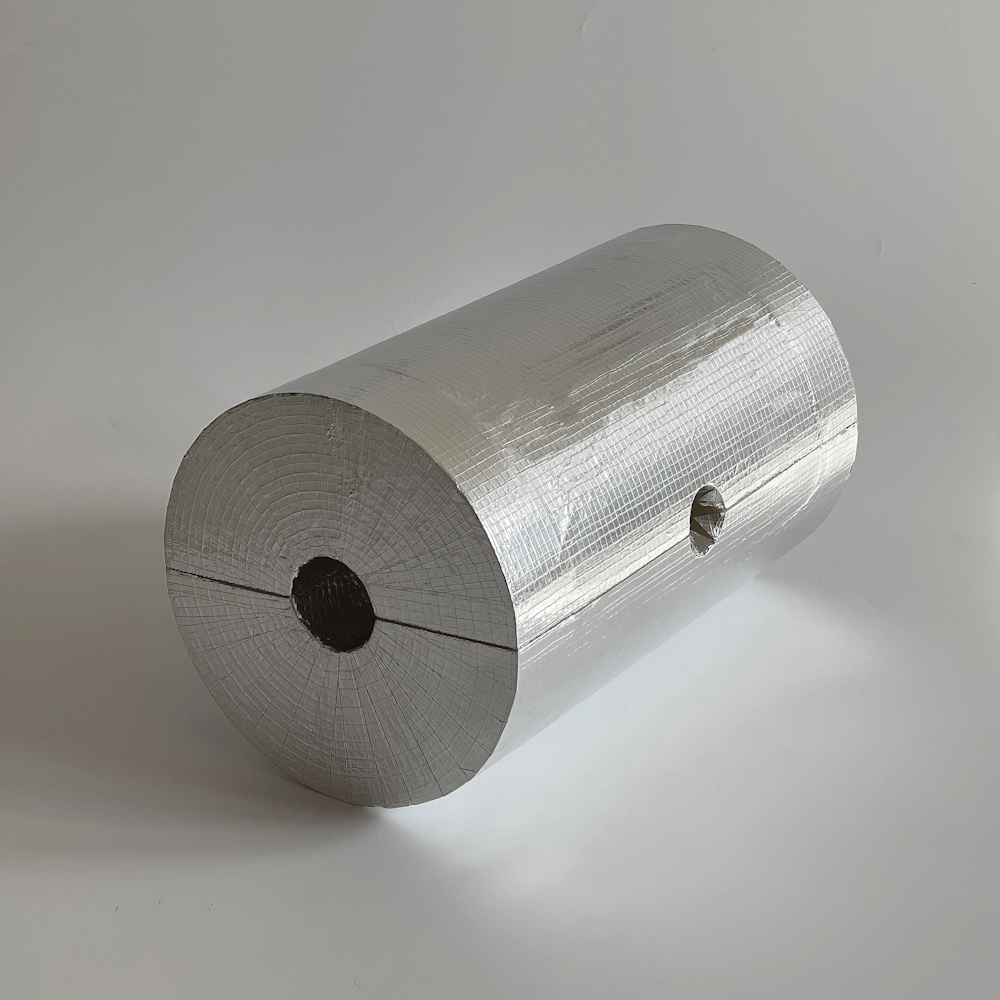

Our product range of pipe insulation in PUR and PIR combines high insulation value with a smooth surface that enables easy wiping and cleaning with high-pressure systems.

The surface material is designed for low toxicity applications, including direct food contact in accordance with EU Directive 2011/10/EC. Dan-isoCLEAN pipe insulation shells are a waterproof solution that effectively protects the pipes against corrosion and can be cleaned with a high-pressure cleaner.

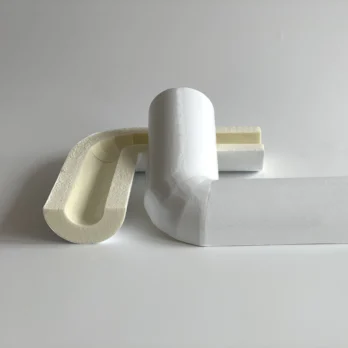

The insulation is installed quickly and can be flexibly adapted to any piping. The rigid foam is pressure resistant so that pipe bowls and bends can be reopened for inspection. Pur and PIR pipe insulation and bends have a long life, which gives the best overall economy.

Dan-isoCLEAN pipe insulation is the right solution for industrial refrigeration systems, especially in the food industry, where temperature control, hygiene and energy efficiency are essential. This insulation is designed to meet the strict requirements of food production, while protecting pipes and systems from extreme conditions.

Advantages of molded pipe insulation shells

PUR foam with EN 253 approval:

PUR foam products from Dan-iso are produced according to the EN 253 standards for pre-insulated district heating pipes, which ensures high quality and reliability.

Precise casting processes:

Our molding equipment is equipped with stepless adjustment that ensures accurate mixing ratios down to the smallest gram, resulting in consistent products.

Controlled casting conditions:

The foam production takes place under carefully controlled conditions with a constant temperature, which provides an optimal foaming process and ensures fast and uniform assembly.

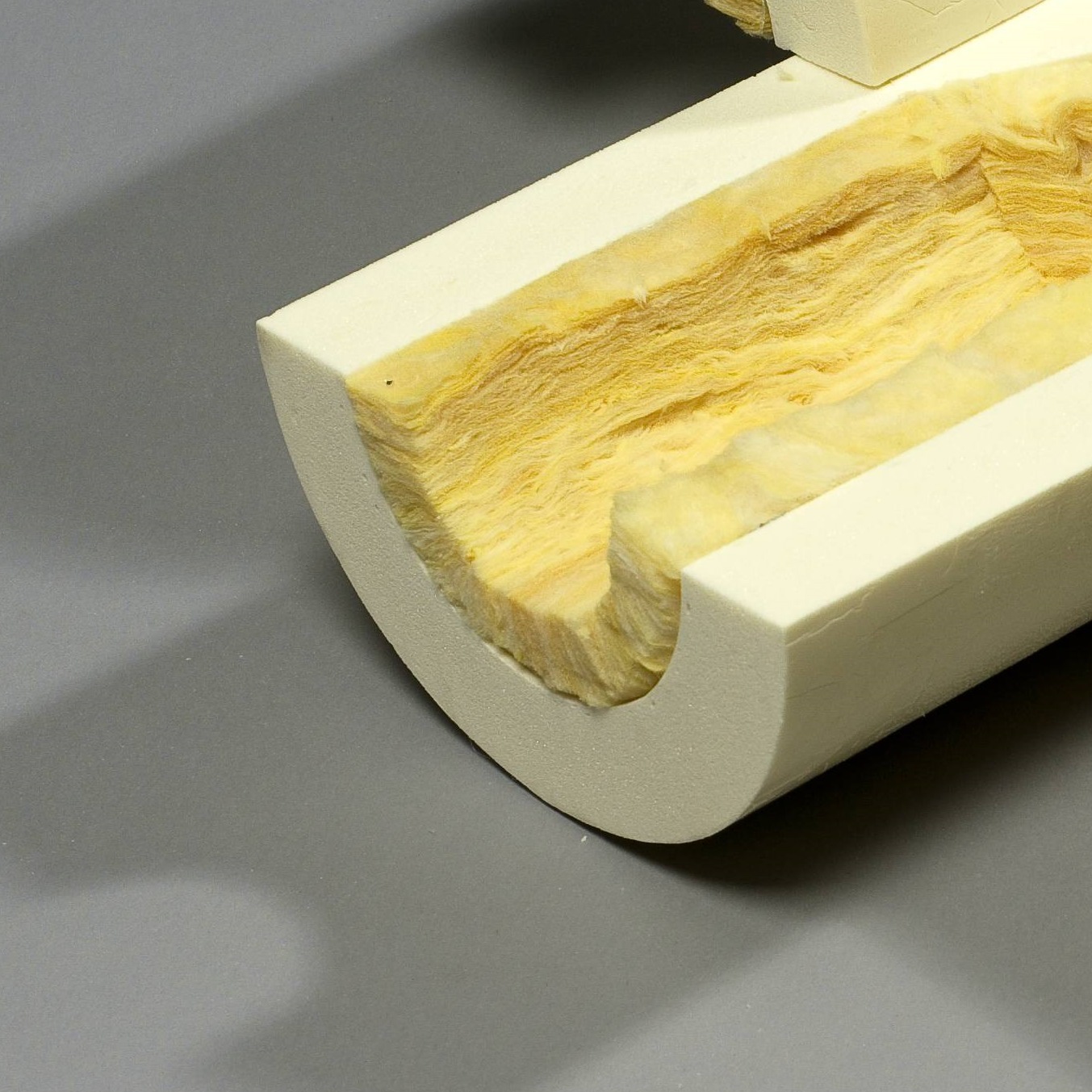

Optimal foam structure:

The carefully adjusted amount of closed cells in the foam gives the best lambda value and thus the lowest possible energy loss.

Strict quality control:

Our quality system includes daily density control, resulting in very tight tolerances and a high finish.

Regular density and compressive strength analysis:

Density and compressive strength are checked weekly in our own laboratory to ensure consistent quality and performance.

Application

Dan-isoCLEAN pipe insulation is particularly suitable for use in industrial refrigeration systems. Refrigeration systems in food production require effective insulation to ensure that temperatures are kept stable and that no condensation or energy loss occurs.

Effective protection for cooling systems

The Dan-isoCLEAN insulation is ideal for both heating and cooling systems, as it helps to maintain the desired temperature in the pipes. In refrigeration systems, where it is important to prevent heat ingress, the insulation ensures that cold air is retained in the system, helping to reduce energy consumption while improving system efficiency.

Prevention of condensation and improved hygiene

In the food industry, hygiene is a top priority. Dan-isoCLEAN pipe insulation prevents condensation on the pipes, which can create a moist environment that promotes the growth of bacteria and mold. This makes the insulation ideal for both storage and transport of food, where a clean and safe environment is necessary.

Flexibility for different cooling systems

Dan-isoCLEAN pipe insulation is versatile and can be used on all types of pipes and systems used in industrial cooling systems, including cooling towers, freezers and conditioning systems. The insulation can be adapted to different pipe sizes and configurations, which makes it ideal for both new installations and for optimizing existing systems.

Long lasting and economical

The pipe insulation is not only effective, but also durable and resistant to the demanding conditions found in industrial refrigeration systems. It protects the pipes against mechanical damage, temperature changes and moisture, which increases the life of the cooling systems and reduces the need for maintenance. This results in savings on both energy and maintenance in the long term.

Technical data sheet

Download product sheet

Technical specifications

| Material properties | Value | Standard |

|---|---|---|

| Density | 68 kg/m3 (±8 kg/m3) | ISO 845 (/DIN 53420-78) |

| Closed cells | ≥ 88 % | ISO 4590 |

| Cell size | < 0.5 mm | EN253 5.3.2.1 |

| Water absorption during boiling | Mean value 4.4 % Vol | EN253 5.3.5 |

| Compressive strength, radial | ≥ 0.40 Mpa | ISO 844 |

| E-module, radial | ≥ 9.5 MPa | ISO 844 |

| Dimensional stability | ||

| -30 C° | 48h: 0.0 % vol | |

| +100 C° | 48h: -1.0 % vol | ISO 2796 (/DIN 53431-77) |

| +150 C° | 48h: -1.4 % vol | |

| Thermal Insulation Value (thermal conductivity) | ||

| λ10 | 0.0238 W/m*K | |

| λ20 | 0.0247 W/m*K | ISO 8301 / ASTM C518 |

| λ50 | 0.0284 W/m*K | |

| Fire class | B3 | DIN 4102 Part 1 |