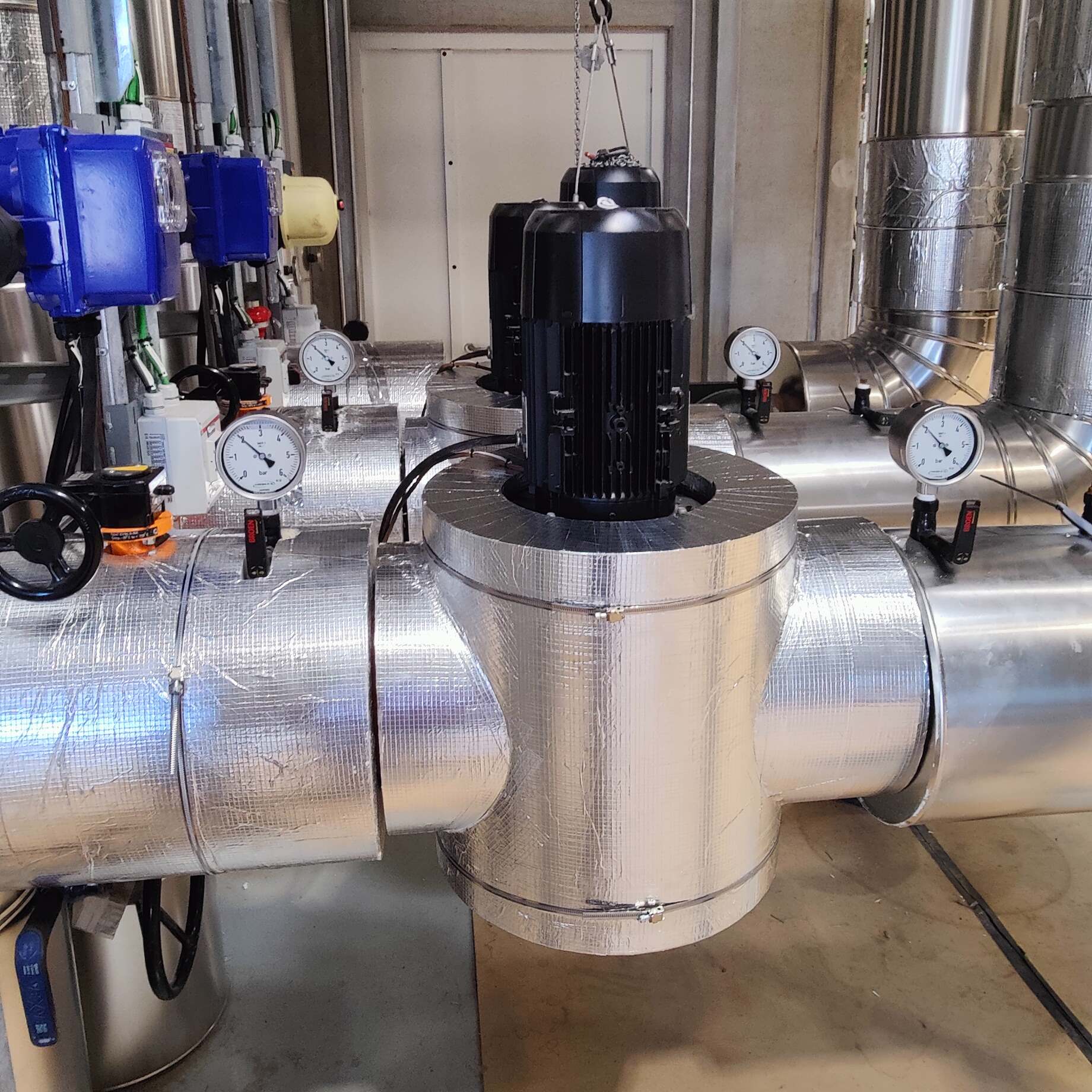

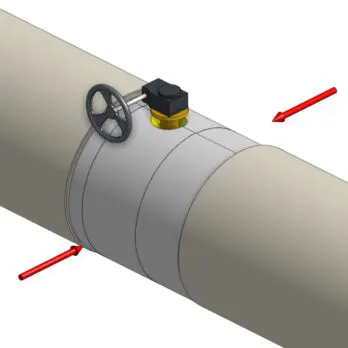

High performance insulation solution for valve and flange connections

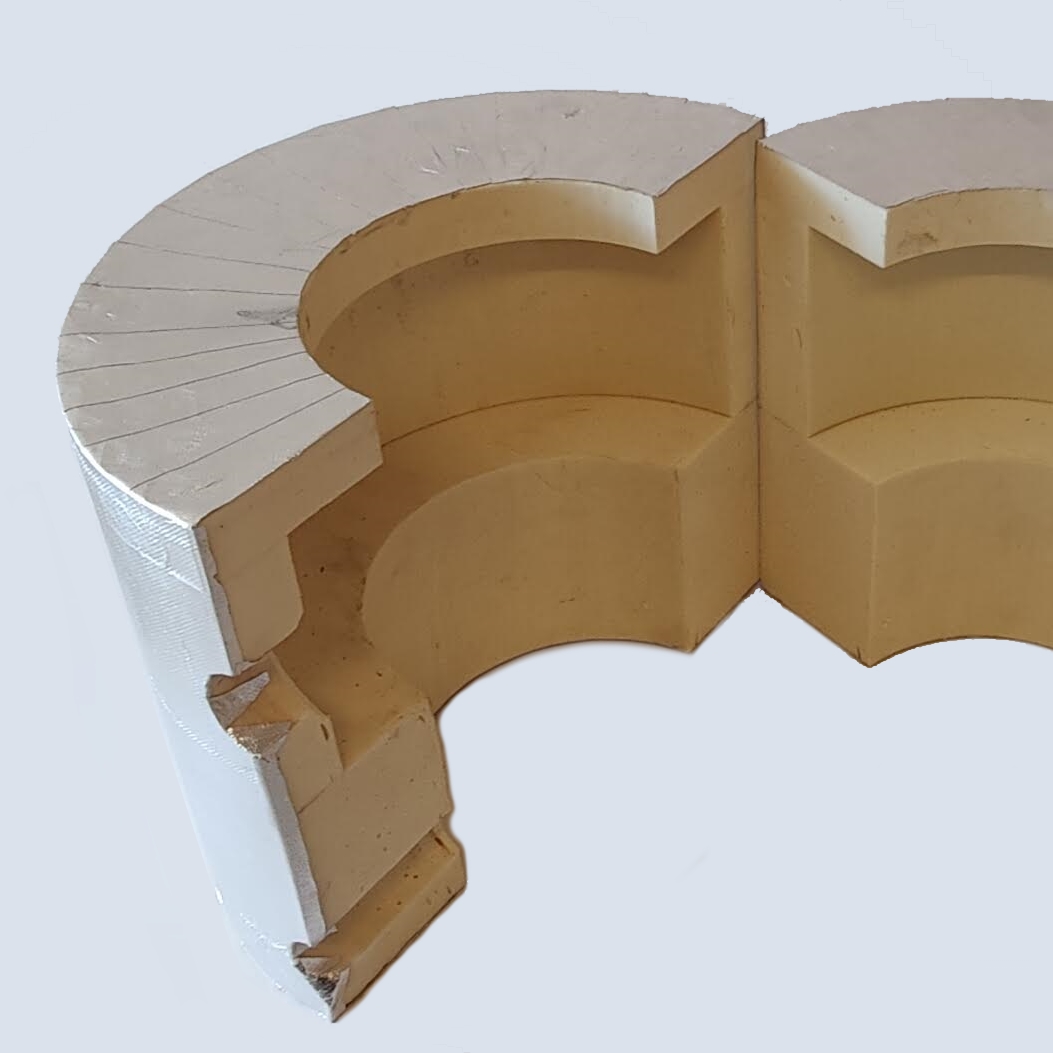

Dan-isoFIT is a premium insulation solution designed to minimize heat loss around valves and flange connections in industrial pipe installations. With its high insulating ability and durable low-emissivity coating, it is perfect for both heating and cooling systems where precise insulation is required.

Important properties

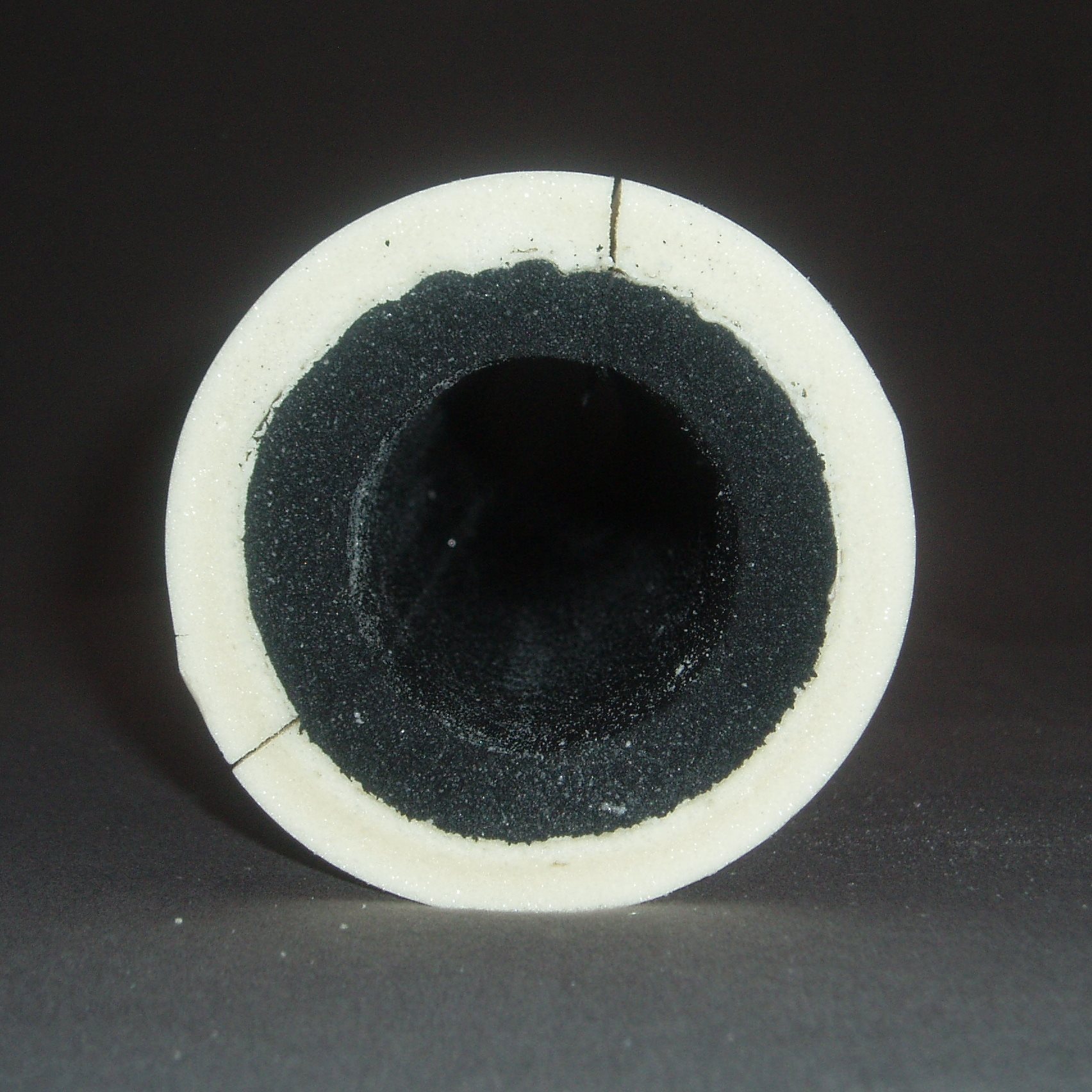

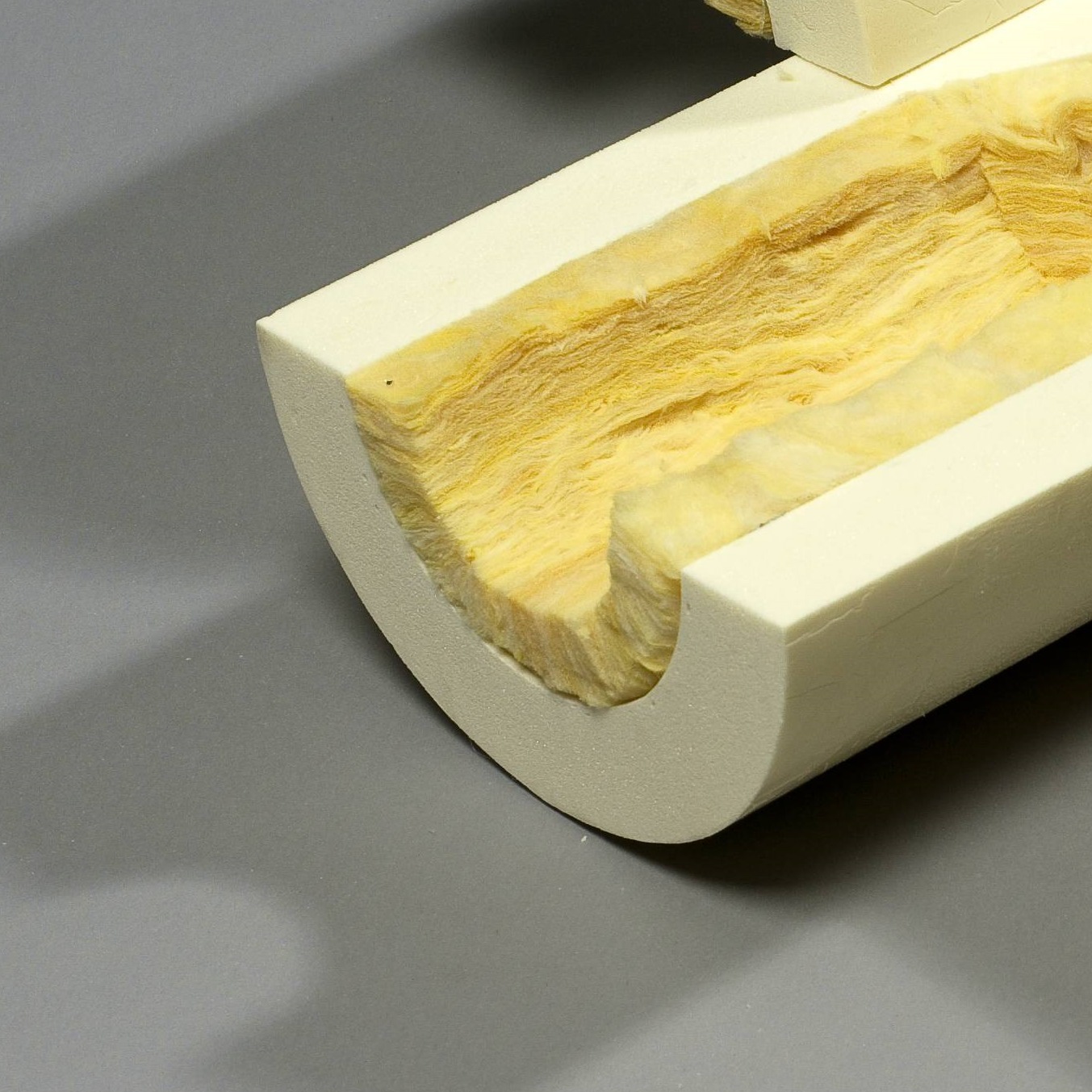

Effective insulation:

Made of rigid polyurethane foam with a protective coating that reduces heat loss and resists environmental influences.

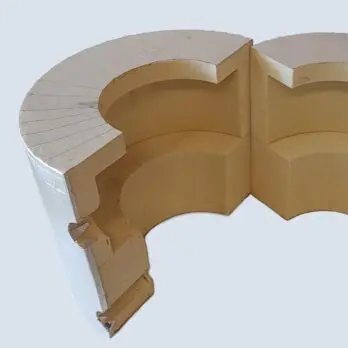

Easy installation:

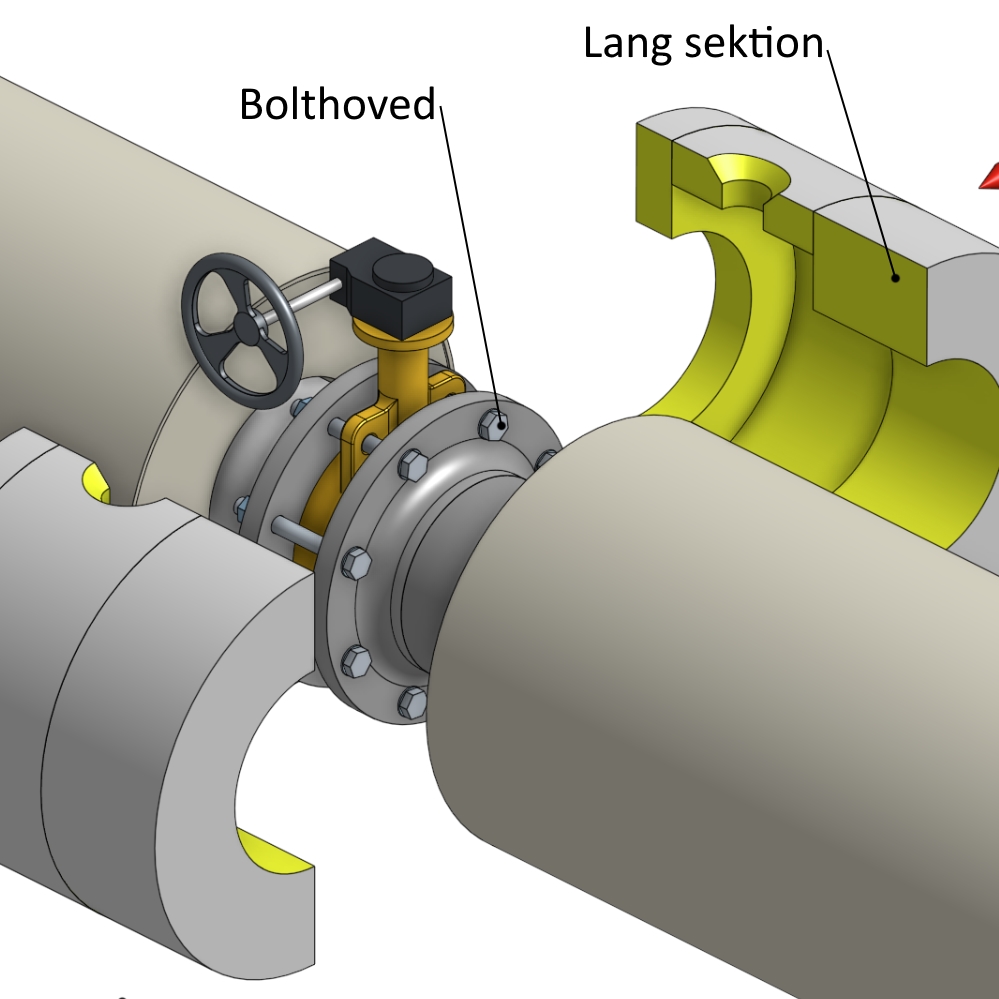

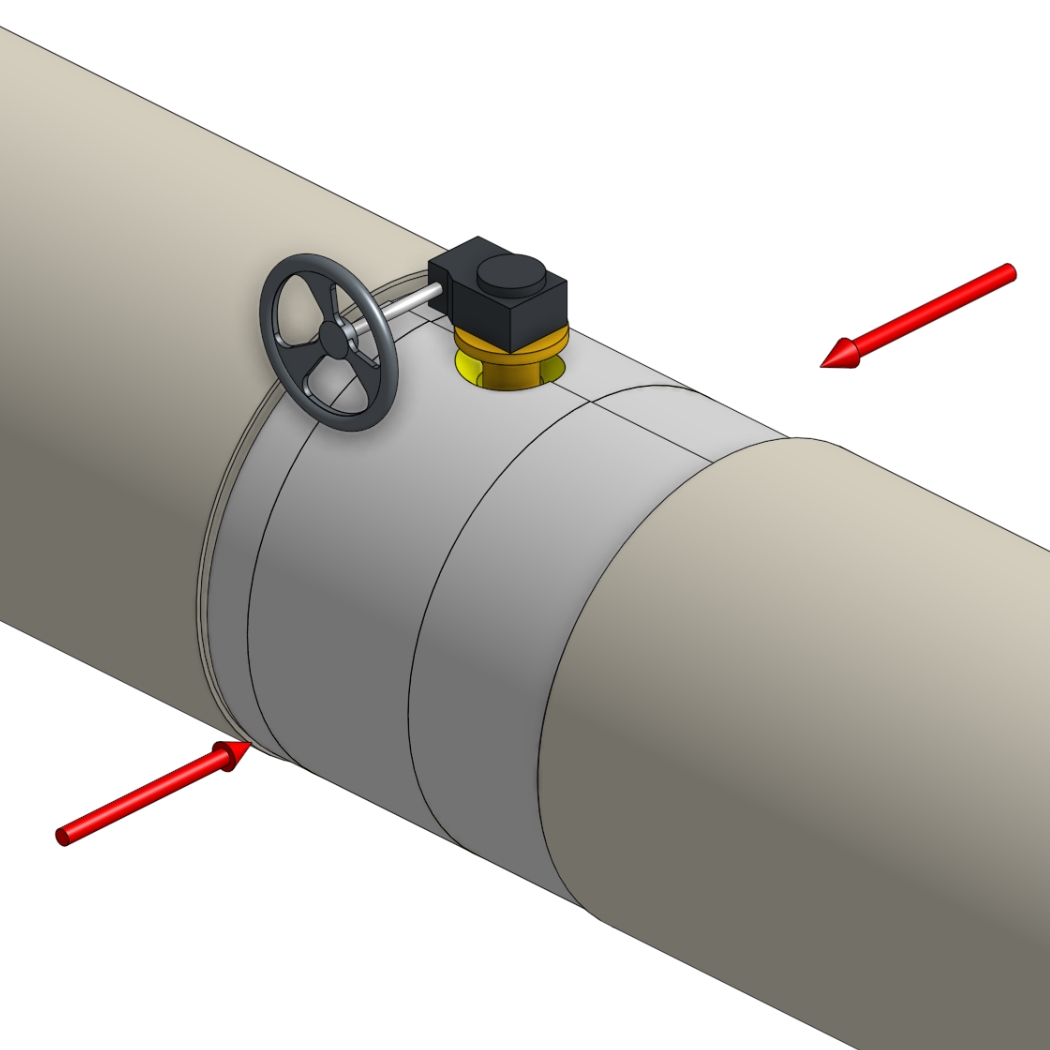

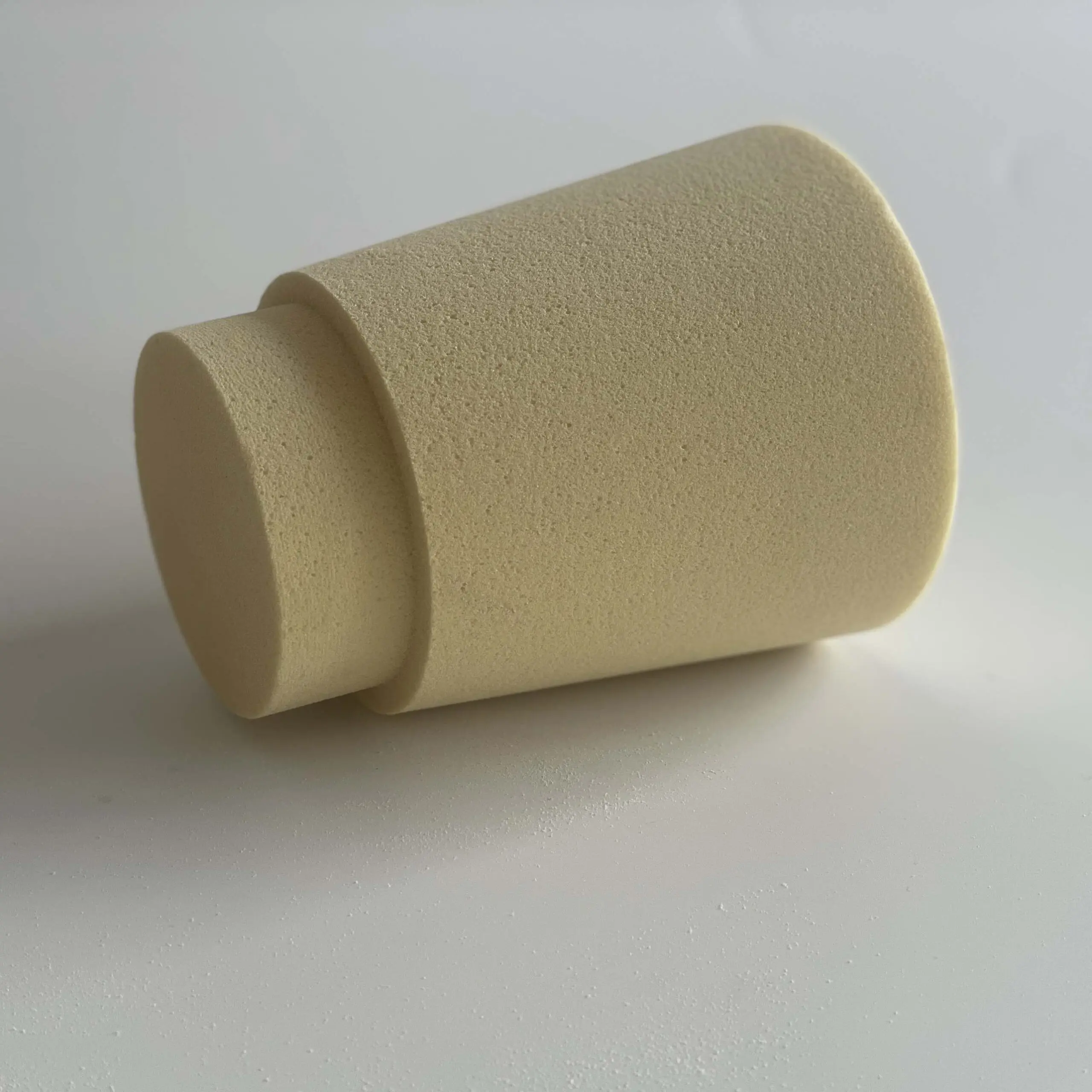

Supplied as ready-to-mount half-shells, designed for a precise fit that maximizes energy savings and makes installation simple.

Durable:

Withstands temperatures up to 148°C.

Tailored Fit:

Can be produced in various sizes to suit most valve and flange connections in the industry.

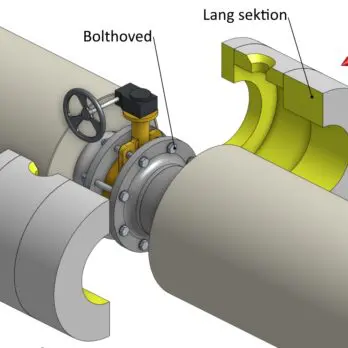

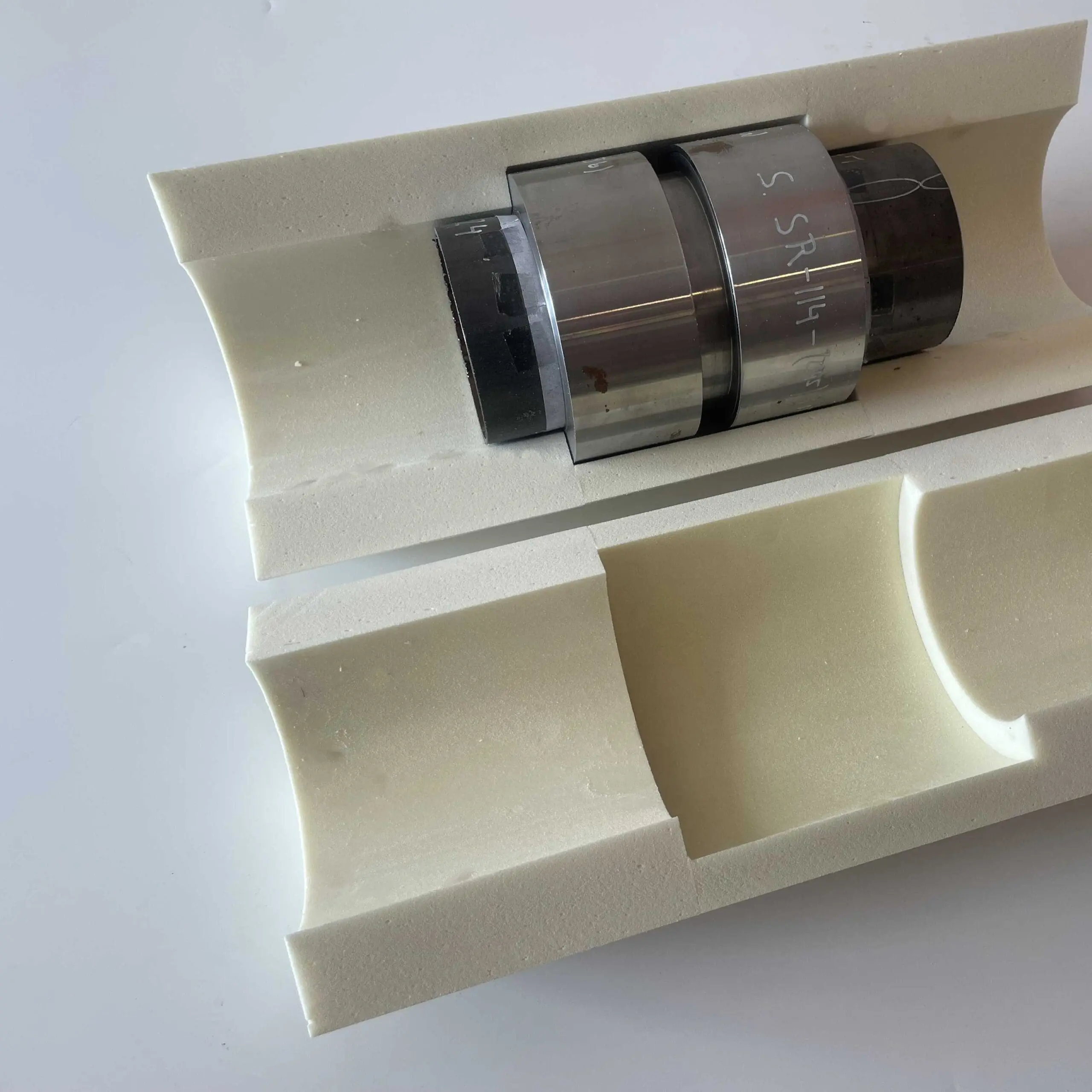

Fast installation

Place the two half cups around the valve or connection. Secure with the included steel clamp and tighten.

The tailored designs also ensure easy disassembly for inspection without damaging the surrounding insulation.

Eiif has published a sensational Whitepaper specifically concerning the often overlooked insulation of flanges and the pump.

Read more here

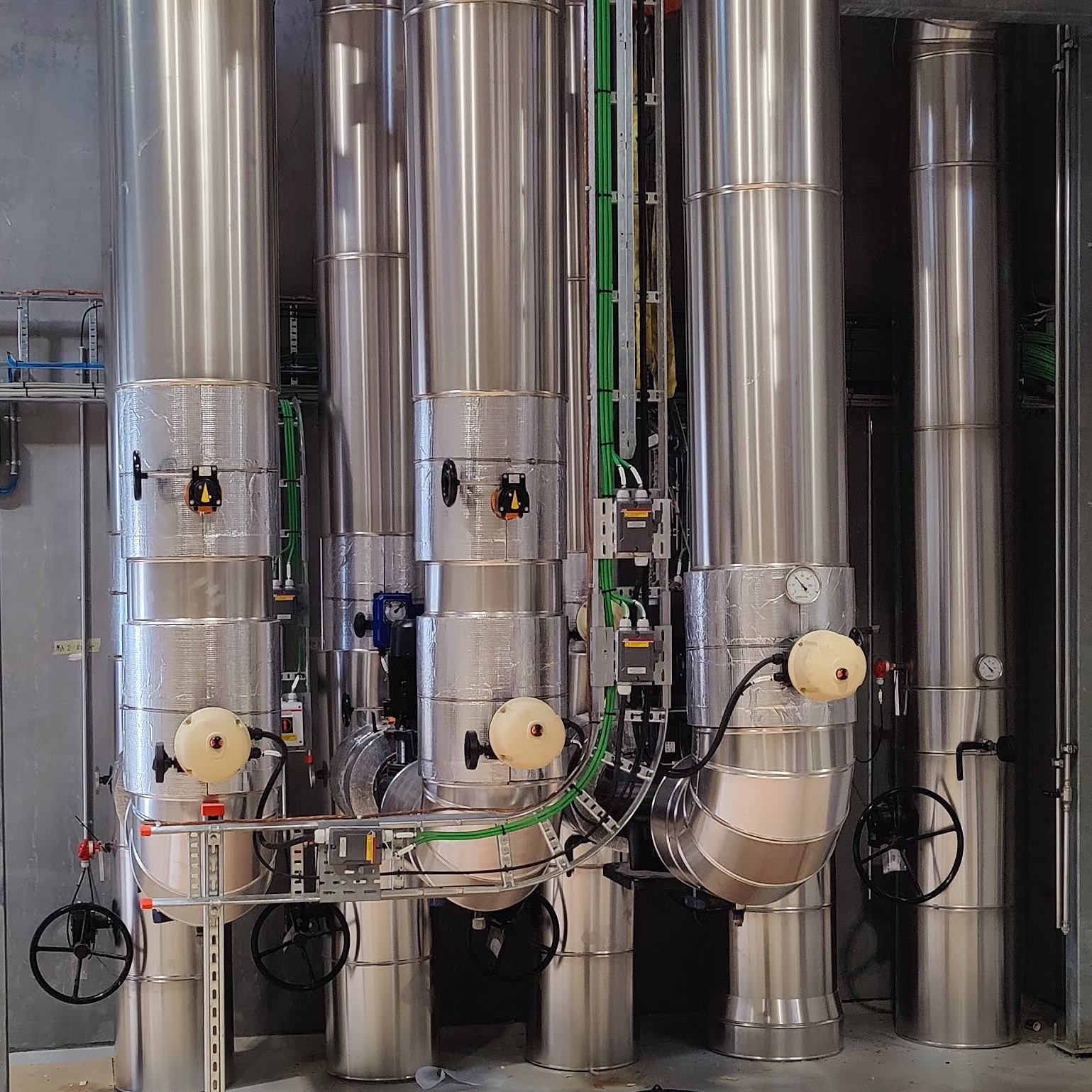

Application

Robust and simple insulation solution for valves

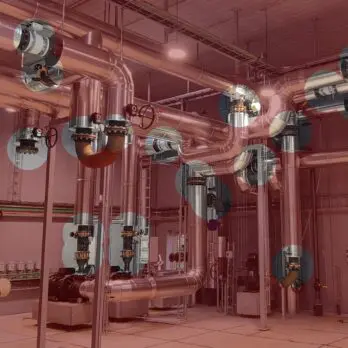

Due to the complexity of their geometry, valves, flanges and other fittings in industrial systems are often left uninsulated, leading to significant energy losses.

Dan-isoFIT pipe insulation is designed to solve this specific problem by providing a robust and simple insulation solution for valves and other irregularly shaped equipment. The tube cups are prefabricated and tailored to fit specific valve types, ensuring minimal heat loss and maximum energy efficiency.

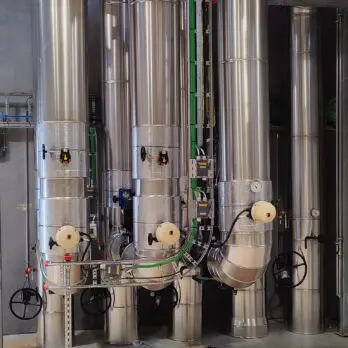

Cost effective strategy for industries

Dan-isoFIT pipe insulation is a smart, cost-effective strategy for industries aiming to reduce their carbon footprint, save energy and lower operating costs.

Technical data sheet

Contact us for product sheet.

Download our Dan-isoFIT White paper below.

Technical specifications

| Material properties | Value | Standard |

|---|---|---|

| Temperature rating (environment) | My. -20°C, max. 60°C | |

| Temperature rating (pipe) | My. -40°C, max. 140°C | |

| Density | 68 kg/m3 (±8 kg/m3) | ISO 845 (/DIN 53420-78) |

| Closed cells | ≥ 88 % | ISO 4590 |

| Cell size | < 0.5 mm | EN253 5.3.2.1 |

| Water absorption during boiling | Mean value 4.4 % Vol | EN253 5.3.5 |

| Compressive strength, radial | ≥ 0.40 Mpa | ISO 844 |

| E-module, radial | ≥ 9.5 MPa | ISO 844 |

| Dimensional stability | ||

| -30 C° | 48h: 0.0 % vol | |

| +100 C° | 48h: -1.0 % vol | ISO 2796 (/DIN 53431-77) |

| +150 C° | 48h: -1.4 % vol | |

| Thermal Insulation Value (thermal conductivity) | ||

| λ10 | 0.0238 W/m*K | |

| λ20 | 0.0247 W/m*K | |

| λ50 | 0.0284 W/m*K | |

| Fire class | B3 | DIN 4102 Part 1 |