The ideal insulation solution for effective thermal protection

Industrial and technical applications

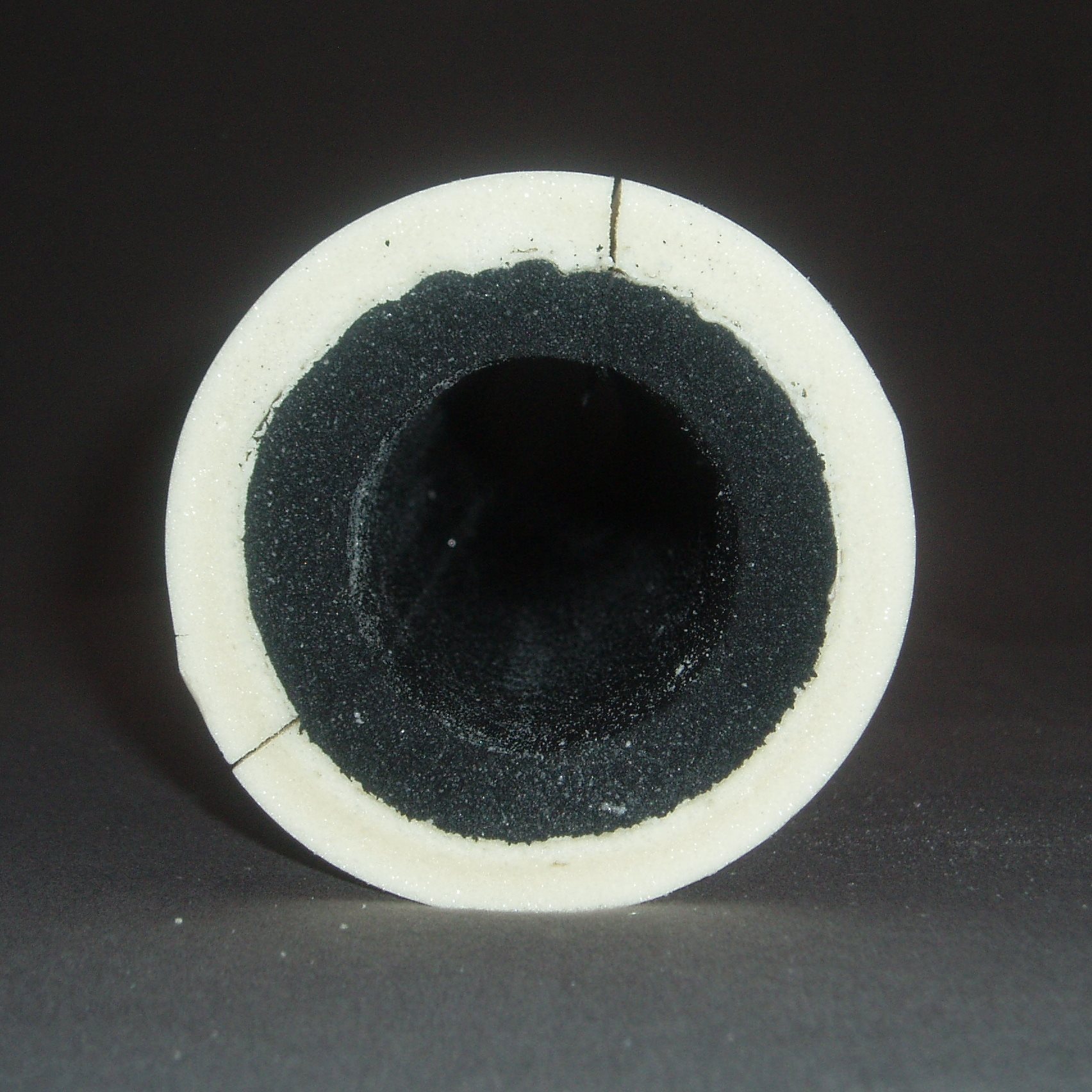

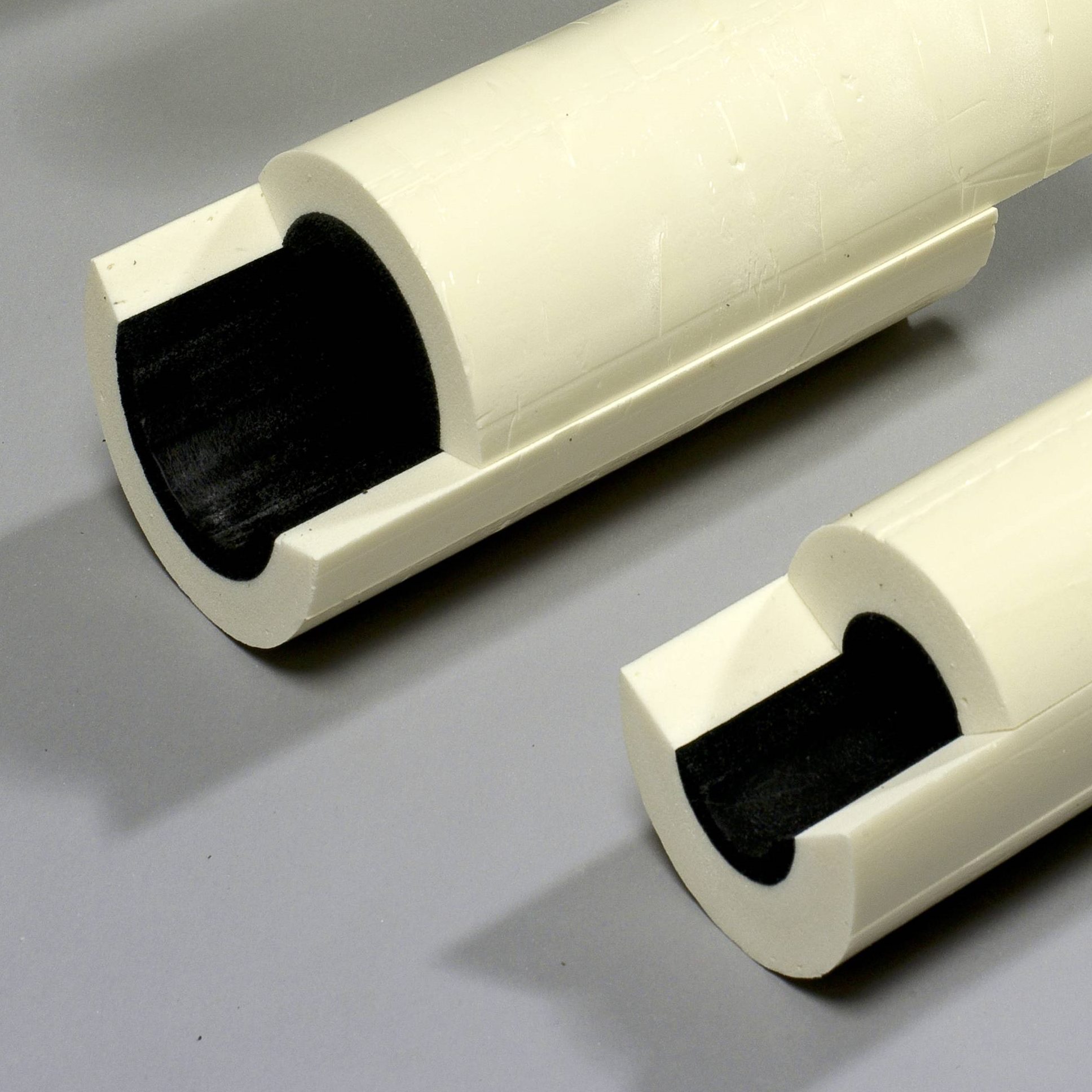

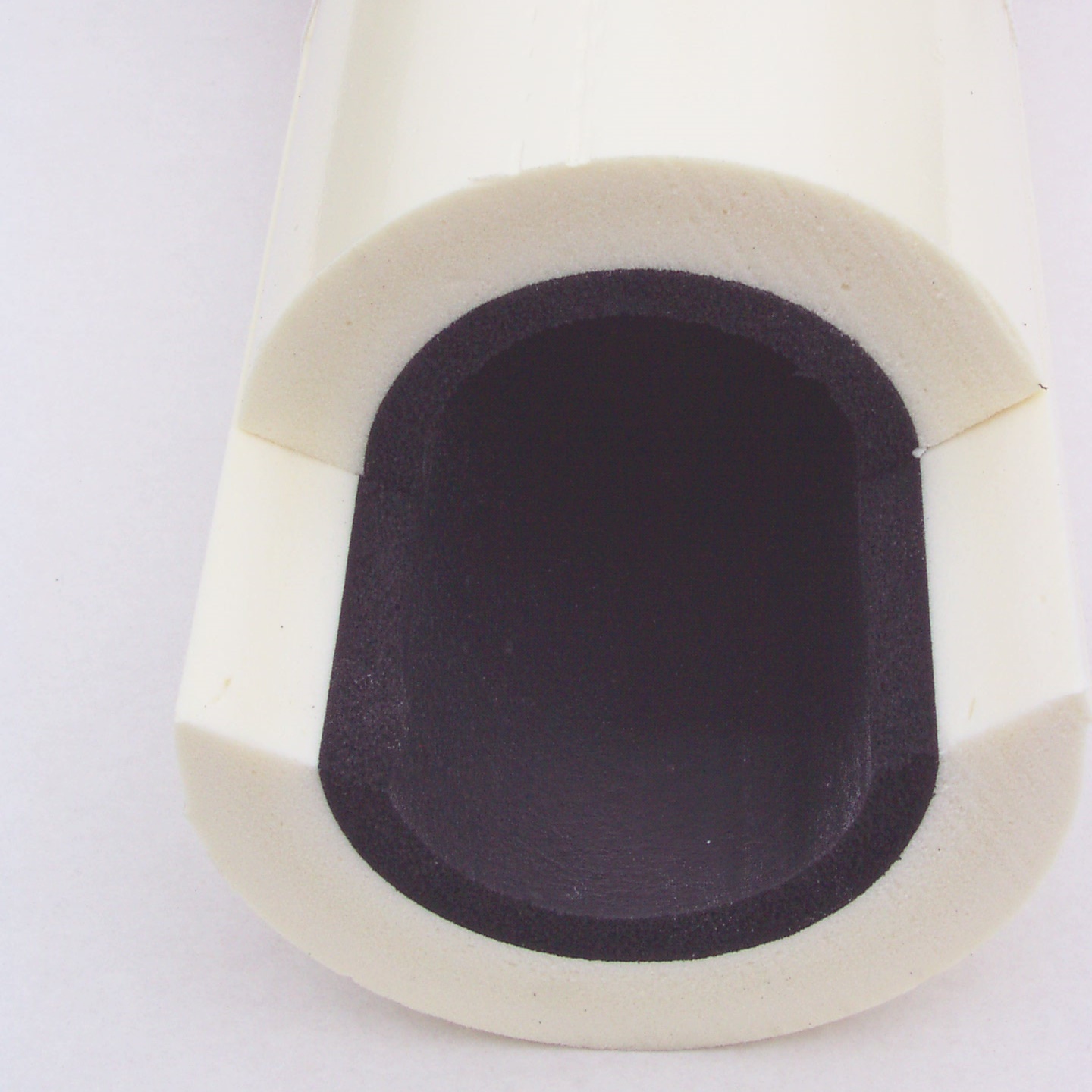

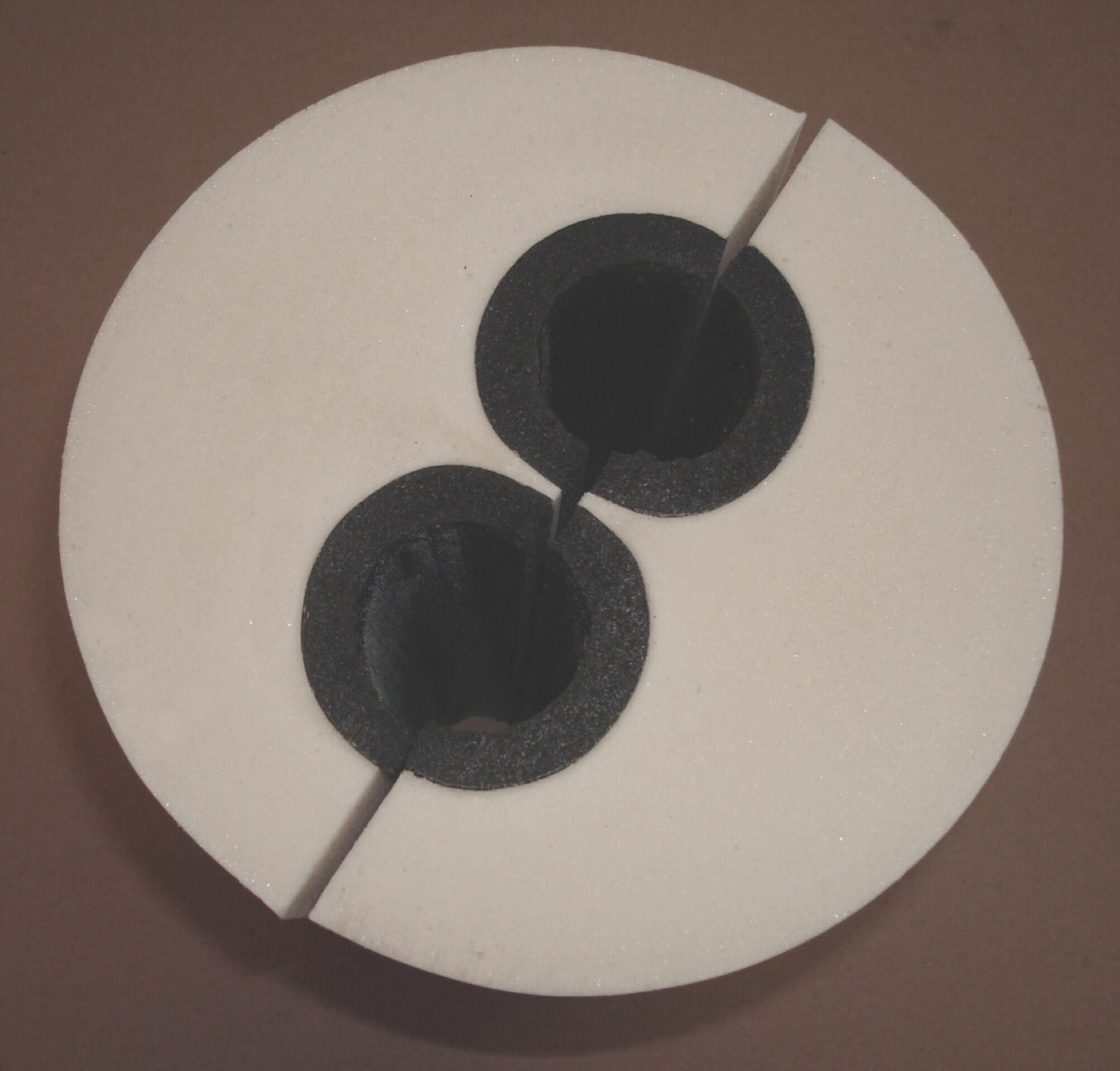

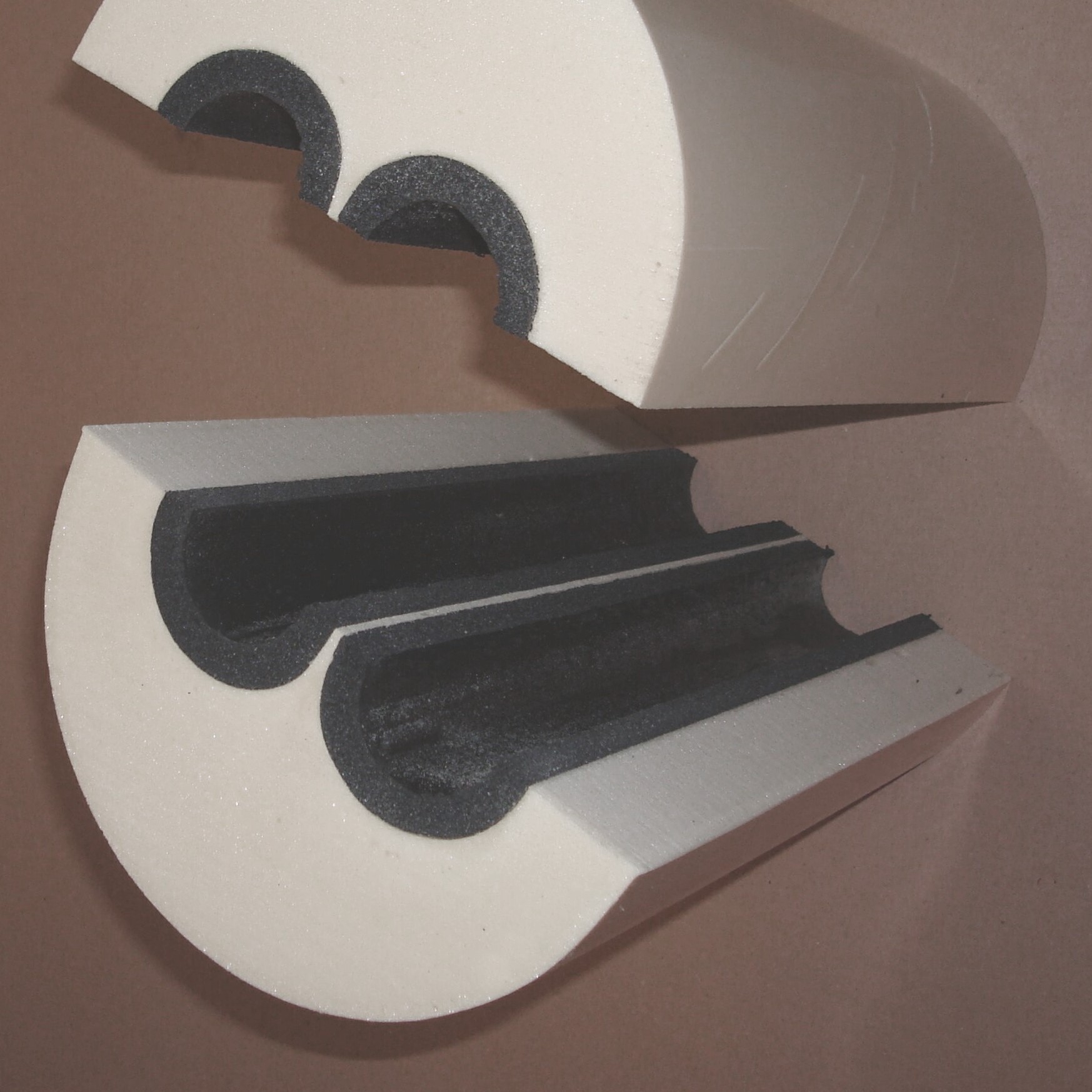

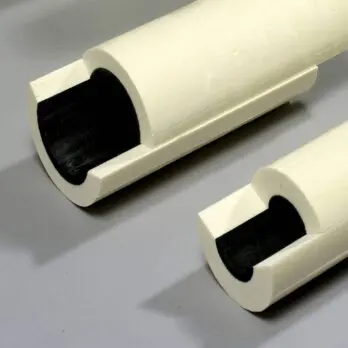

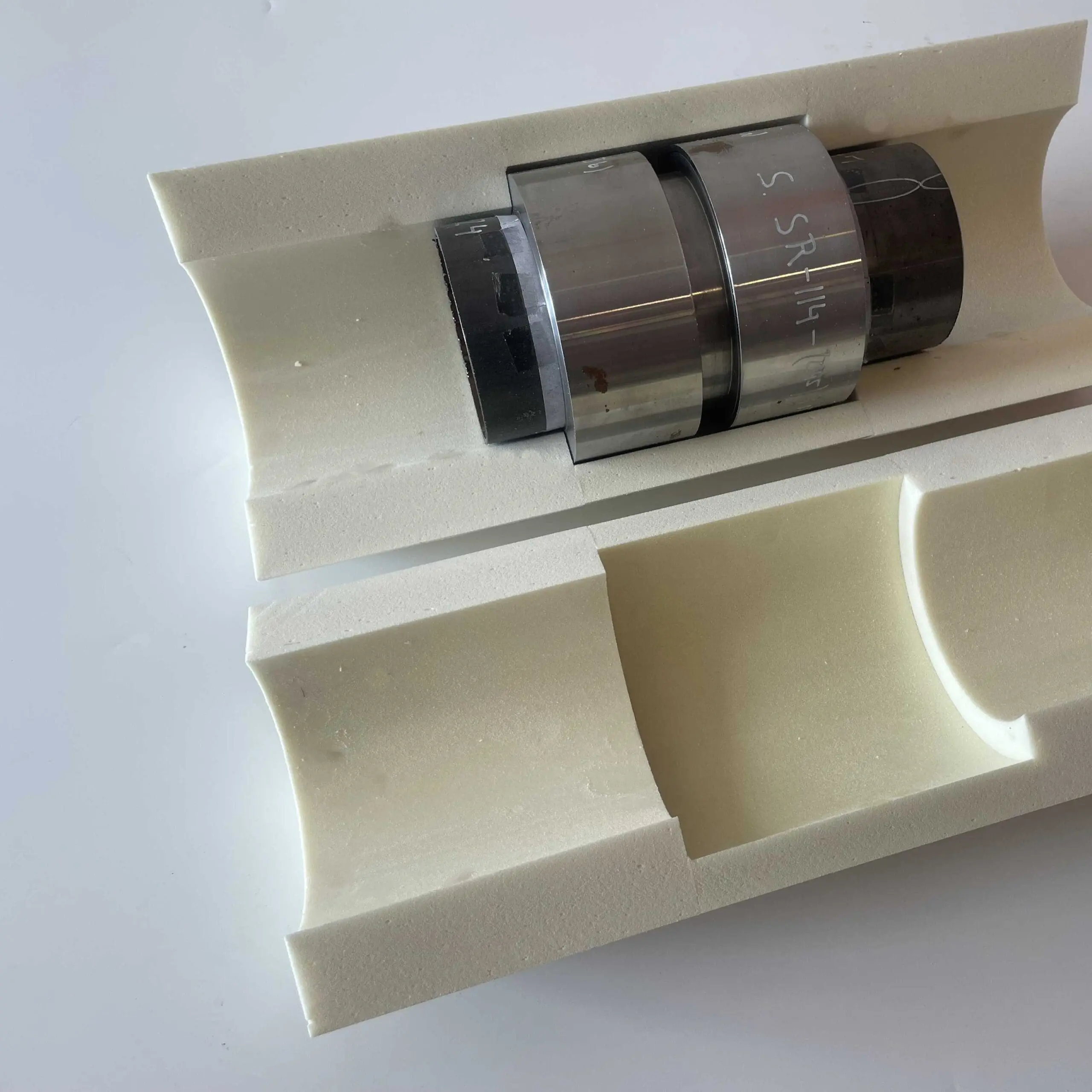

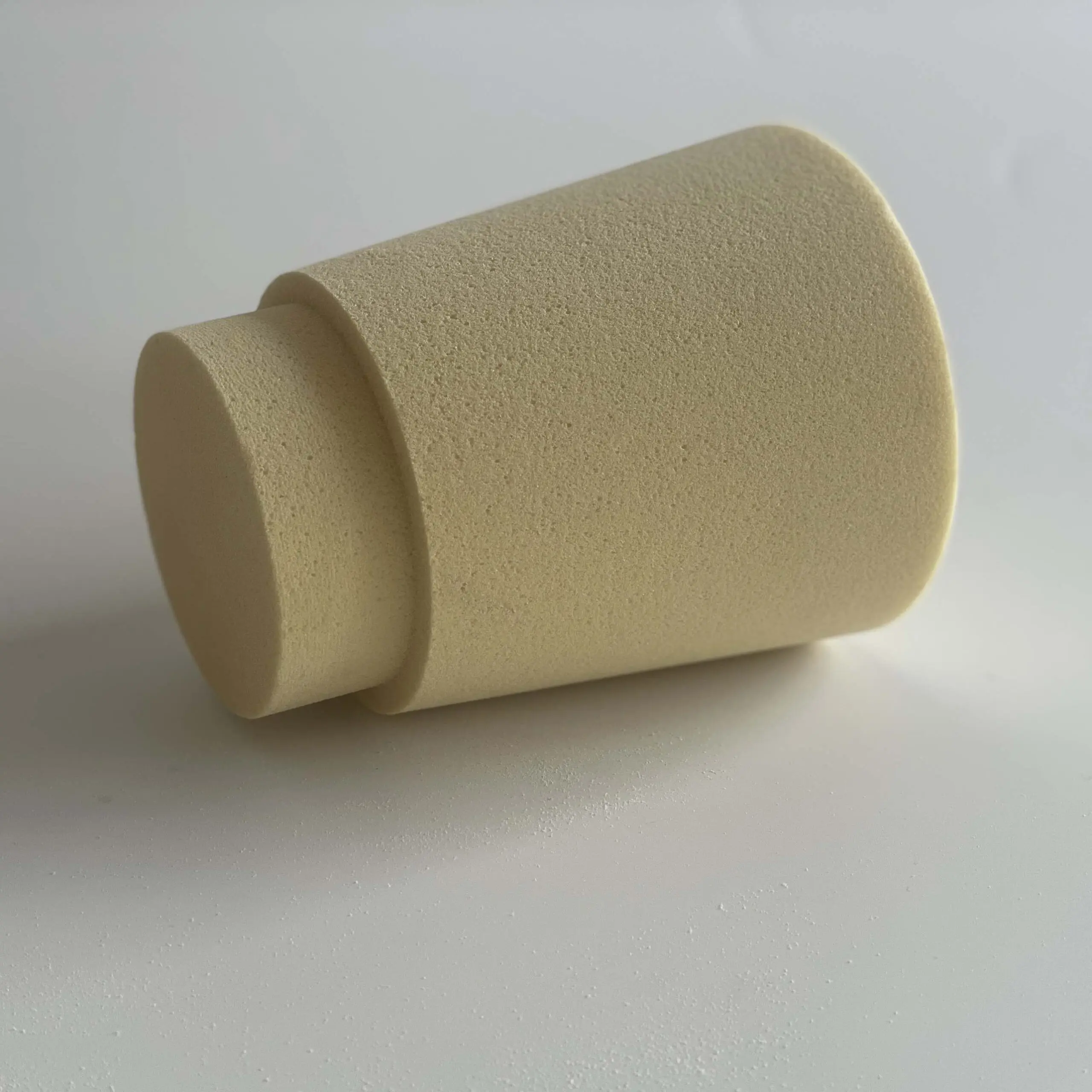

We offer polyurethane (PUR) technical pipe insulation in various diameters, perfect for both industrial and technical applications.

Flexible solutions for your needs

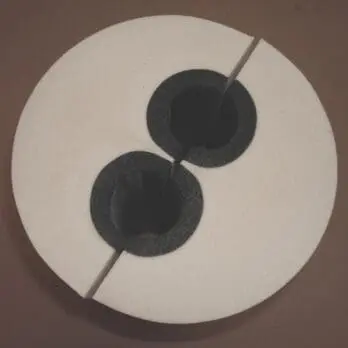

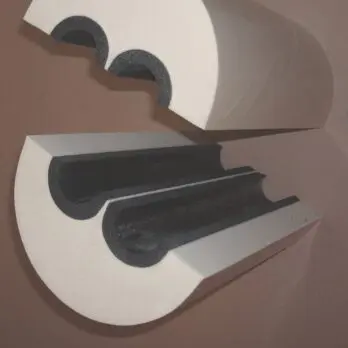

Our PUR pipe insulation is available in diameters from Ø77 mm to Ø450 mm. It can be supplied in a standard length of 320 mm or tailored to specific lengths. We also offer T-pieces with cellular rubber inserts for easy installation in joints.

Effective heat protection and easy installation

PUR pipe insulation reduces heat loss and ensures stable temperature control. It is easy to install and protects against energy loss. Our solutions are designed for long-term durability and high performance in both new and renovation projects.

Application

Use of polyurethane pipe insulation with cellular rubber inserts

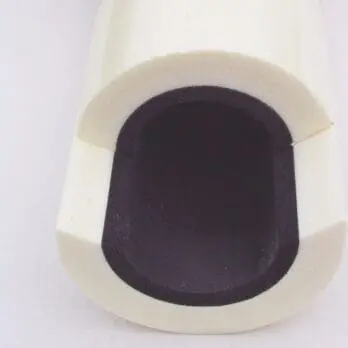

Polyurethane (PUR) pipe insulation with cellular rubber inserts is ideal for systems where both high thermal insulation and mechanical protection are required. This solution combines the thermal efficiency of PUR with the additional protective layer of cellular rubber inserts, making it perfect for demanding industrial and technical applications.

Industrial pipe installations

PUR pipe insulation with cellular rubber insert is suitable for large industrial pipe installations that are exposed to high temperatures and physical stress. The cellular rubber insert protects against mechanical damage and at the same time provides extra insulation, while PUR prevents heat loss and ensures energy-efficient operation.

HVAC Systems

In HVAC (Heating, Ventilation, and Air Conditioning) systems, pipe insulation with cellular rubber inserts is used to maintain stable temperatures in pipes and ducts. The cellular rubber insert reduces condensation and protects against mechanical damage, while the PUR insulation effectively prevents energy loss.

Cooling systems

For cooling systems where pipes and components are exposed to both high and low temperatures, PUR pipe insulation with cellular rubber inserts provides the necessary protection. The cellular rubber insert improves insulation and prevents frost damage, while reducing energy consumption.

The oil and gas industry

In the oil and gas industry, where piping systems often operate under extreme conditions, PUR pipe insulation with cellular rubber inserts is used to protect against both mechanical damage and temperature fluctuations. This solution ensures efficient operation and extended service life of the piping installation.

Construction and renovation

In construction and renovation, PUR pipe insulation with cellular rubber inserts is ideal for installations that require temperature control, such as heating and water pipes. The combination of PUR and cellular rubber inserts provides both good insulation and protection against damage, ensuring long-term durability and efficient operation.

Polyurethane pipe insulation with cellular rubber inserts is a versatile solution that effectively ensures thermal insulation, protects against mechanical damage and reduces energy loss in many different industrial and technical installations.

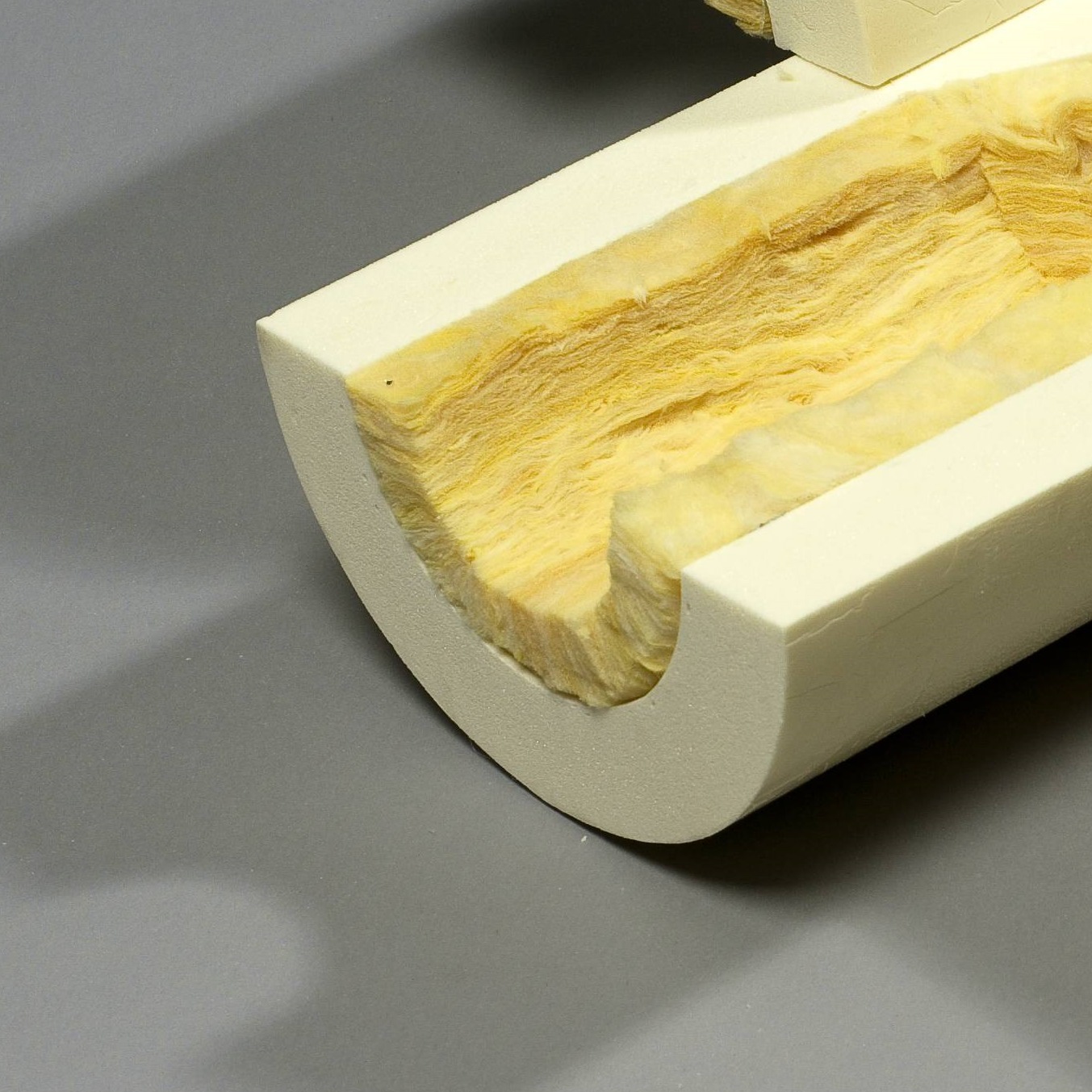

Also explore our Dan-isoMOLD pipe insulation with inner wool protection – Dan-isoMOLD with wool.

Technical data sheet

Contact us for product sheet.

Technical specifications

| Material properties | Value | Standard |

|---|---|---|

| Density | 68 kg/m3 (±8 kg/m3) | ISO 845 (/DIN 53420-78) |

| Closed cells | ≥ 88 % | ISO 4590 |

| Cell size | < 0.5 mm | EN253 5.3.2.1 |

| Water absorption during boiling | Mean value 4.4 % Vol | EN253 5.3.5 |

| Compressive strength, radial | ≥ 0.40 Mpa | ISO 844 |

| E-module, radial | ≥ 9.5 MPa | ISO 844 |

| Dimensional stability | ||

| -30 C° | 48h: 0.0 % vol | |

| +100 C° | 48h: -1.0 % vol | ISO 2796 (/DIN 53431-77) |

| +150 C° | 48h: -1.4 % vol | |

| Thermal Insulation Value (thermal conductivity) | ||

| λ10 | 0.0238 W/m*K | |

| λ20 | 0.0247 W/m*K | ISO 8301 / ASTM C518 |

| λ50 | 0.0284 W/m*K | |

| Fire class | B3 (Normal combustible) | DIN 4102 Part 1 |