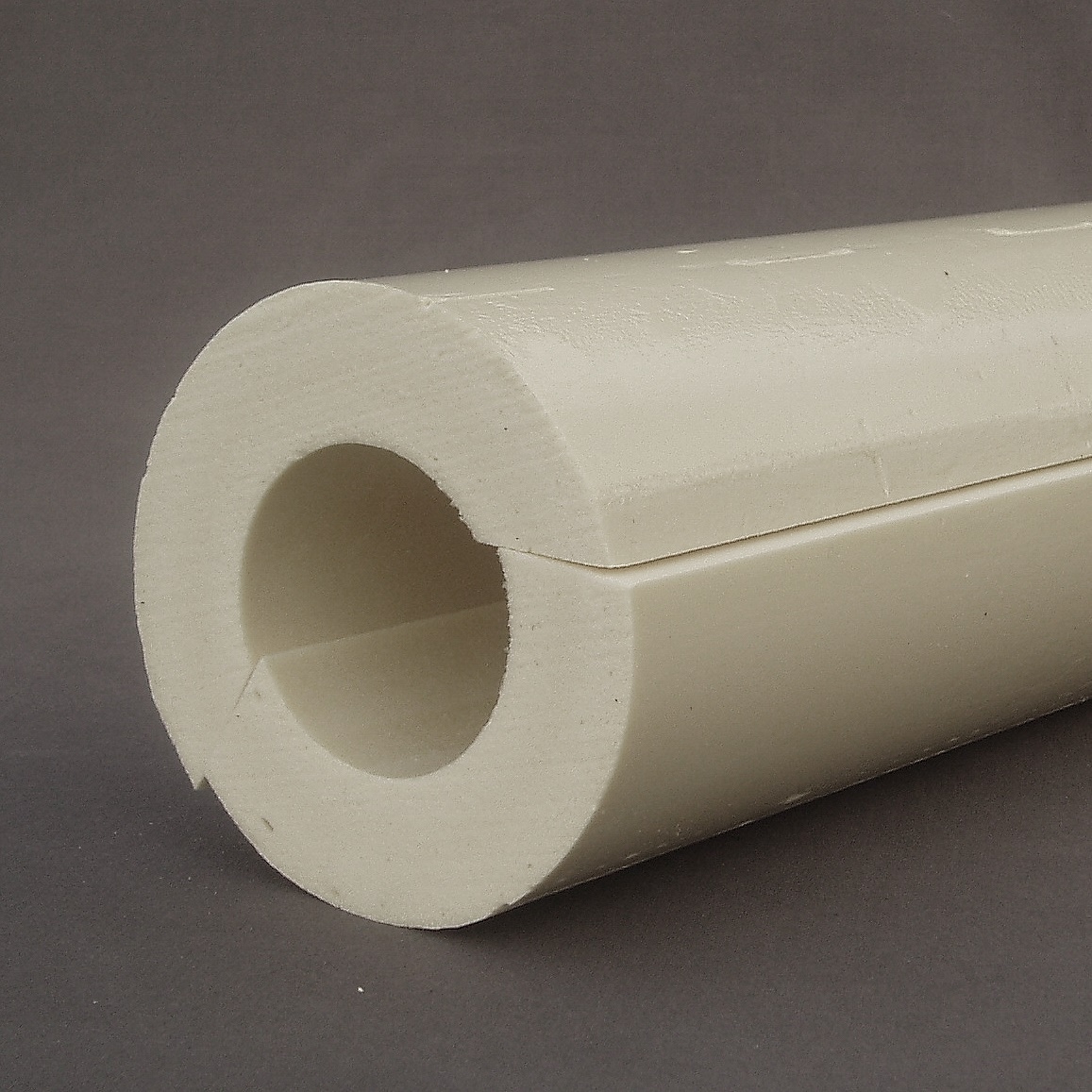

Effective polyurethane pipe insulation with durable pipe bowls

Meets the strict requirements of the EN 253 standard

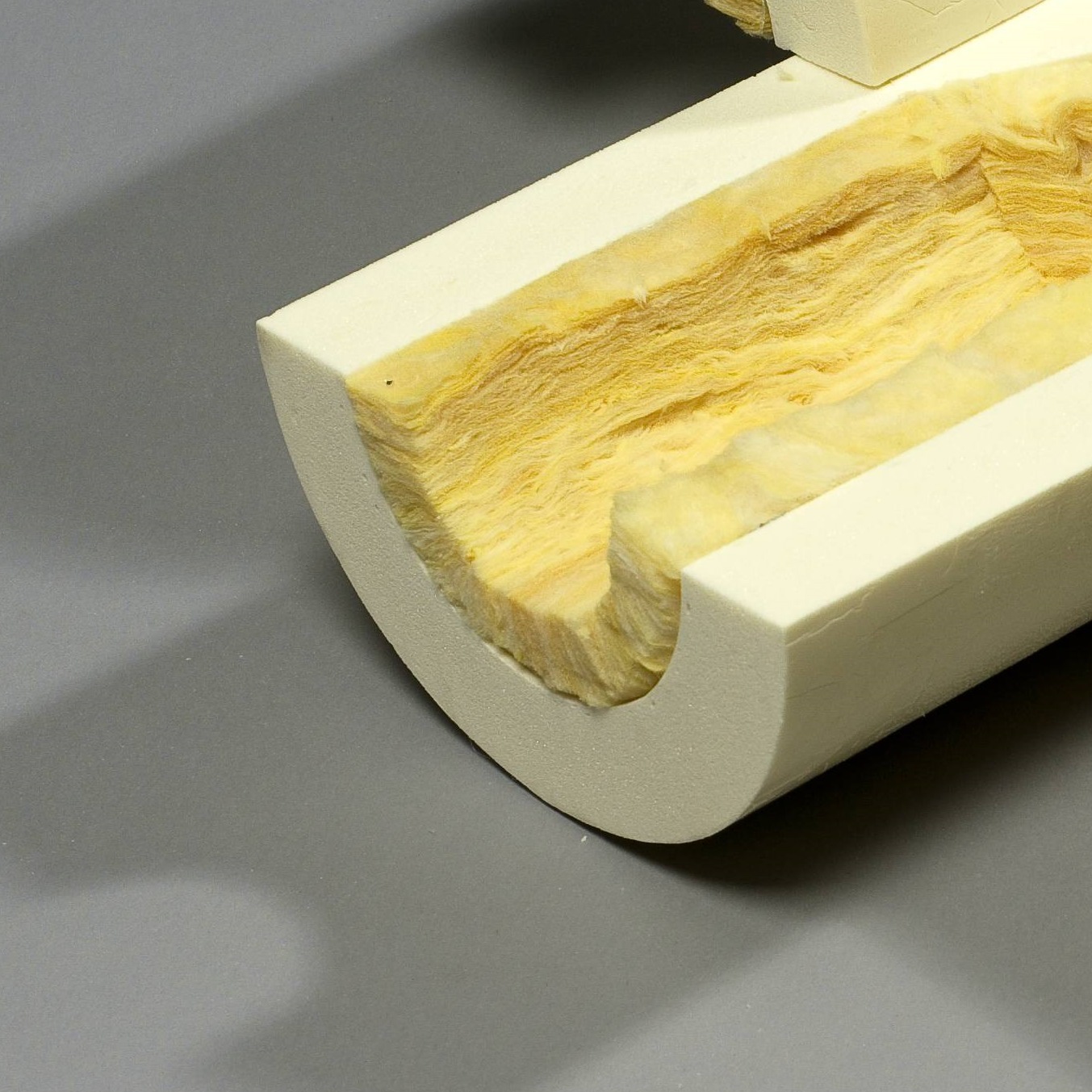

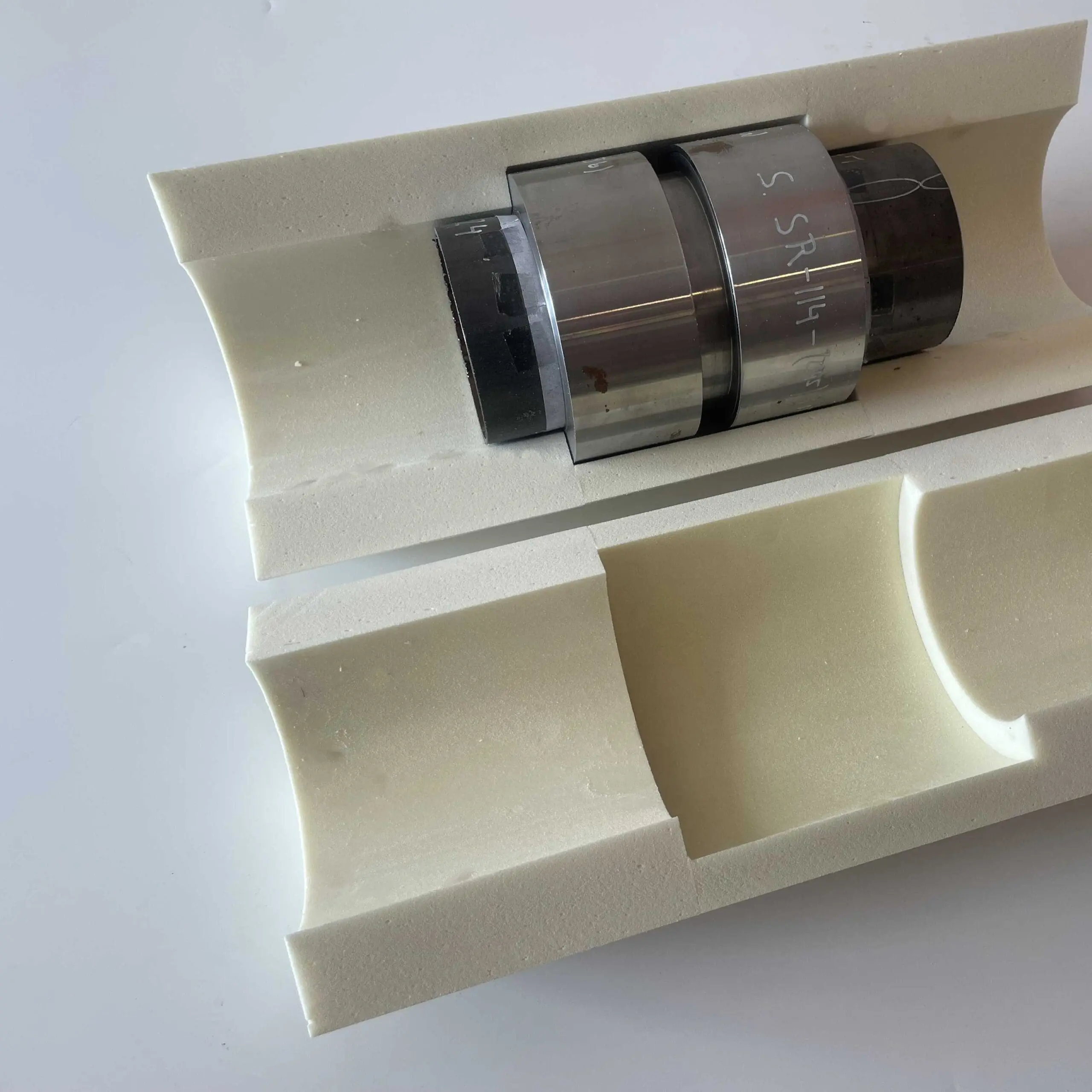

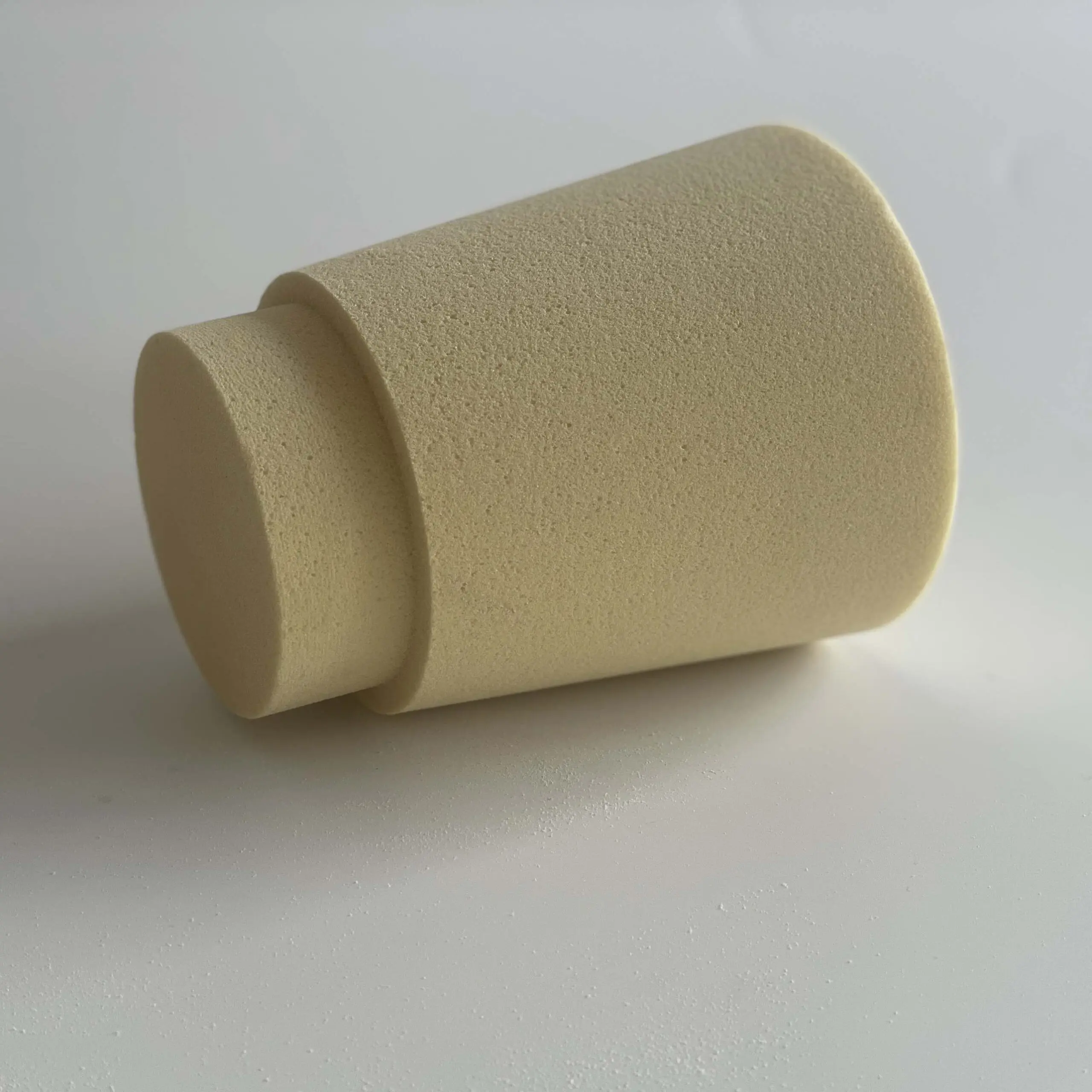

At Dan-iso, we are proud to offer high-quality cast pipe trays, specially developed for insulation in the district heating industry. These pipe bowls are made from an advanced polyurethane type that is used, among other things, in pre-insulated district heating pipes.

Dan-isoMOLD molded pipe insulation cups meet the strict requirements of the EN 253 standard, ensuring that they provide reliable and effective insulation under even the most demanding conditions.

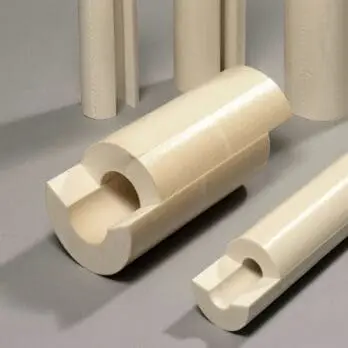

The molded PUR pipe sockets are designed to provide optimal insulation in district heating systems, as well as being extremely suitable for technical insulation in a wide range of industrial sectors where effective thermal insulation is essential.

Whether it is about insulating pipes in power plants, production plants or other industrial installations, our pipe trays provide the necessary protection and energy efficiency.[/vc_column_text]

Flexible dimensions and solutions

Application

The molded pipe trays are designed to provide optimal insulation in district heating systems, for technical insulation, insulation of pipes in power plants, production plants or other industrial installations with the necessary protection and energy efficiency.

Technical data sheet

Contact us for product sheet.

Technical specifications

| Material properties | Value | Standard |

|---|---|---|

| Density | 68 kg/m3 (±8 kg/m3) | ISO 845 (/DIN 53420-78) |

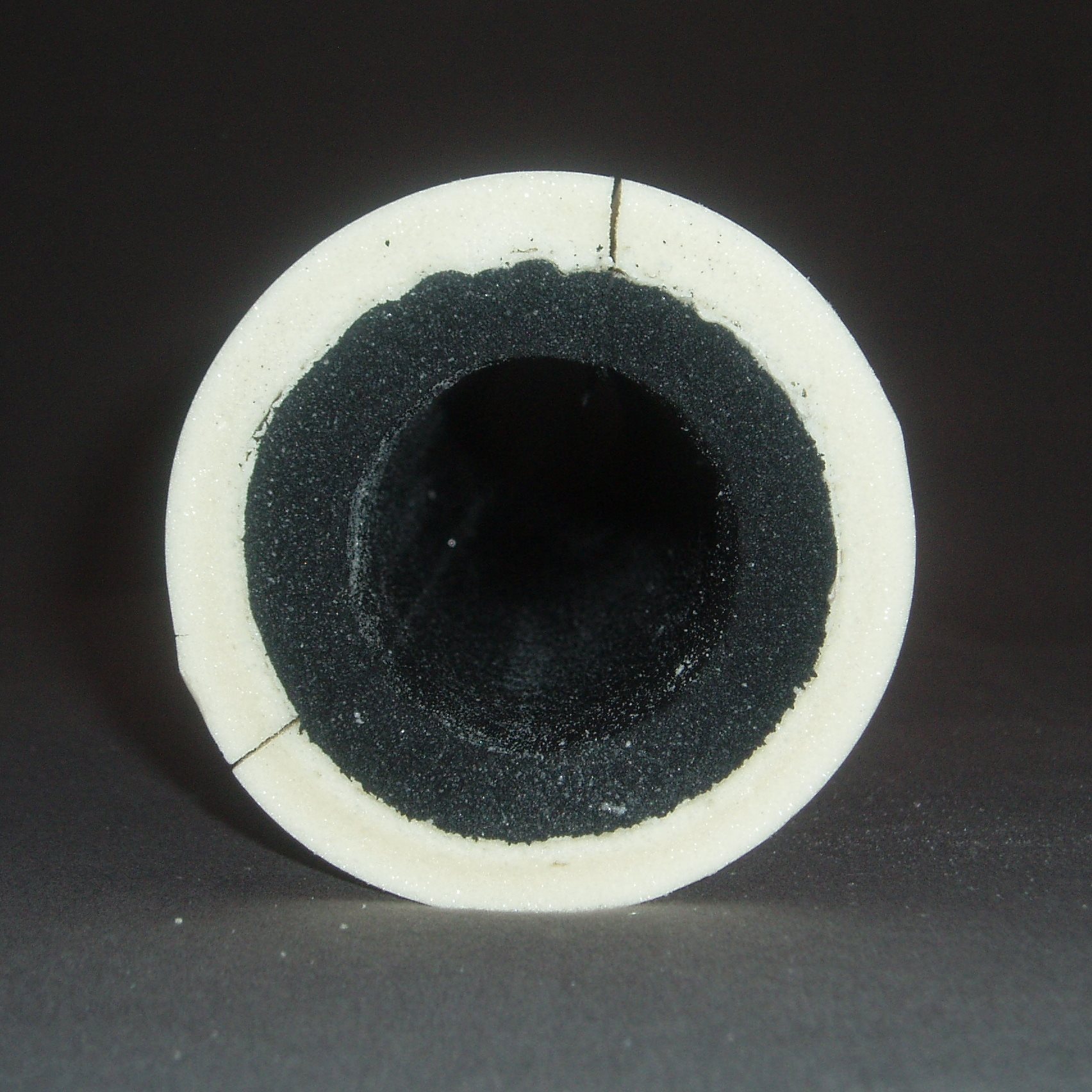

| Closed cells | ≥ 88 % | ISO 4590 |

| Cell size | < 0.5 mm | EN253 5.3.2.1 |

| Water absorption during boiling | Mean value 4.4 % Vol | EN253 5.3.5 |

| Compressive strength, radial | ≥ 0.40 Mpa | ISO 844 |

| E-module, radial | ≥ 9.5 MPa | ISO 844 |

| Dimensional stability | ||

| -30 C° | 48h: 0.0 % vol | |

| +100 C° | 48h: -1.0 % vol | ISO 2796 (/DIN 53431-77) |

| +150 C° | 48h: -1.4 % vol | |

| Thermal Insulation Value (thermal conductivity) | ||

| λ10 | 0.0238 W/m*K | |

| λ20 | 0.0247 W/m*K | ISO 8301 / ASTM C518 |

| λ50 | 0.0284 W/m*K | |

| Fire class | B3 | DIN 4102 Part 1 |