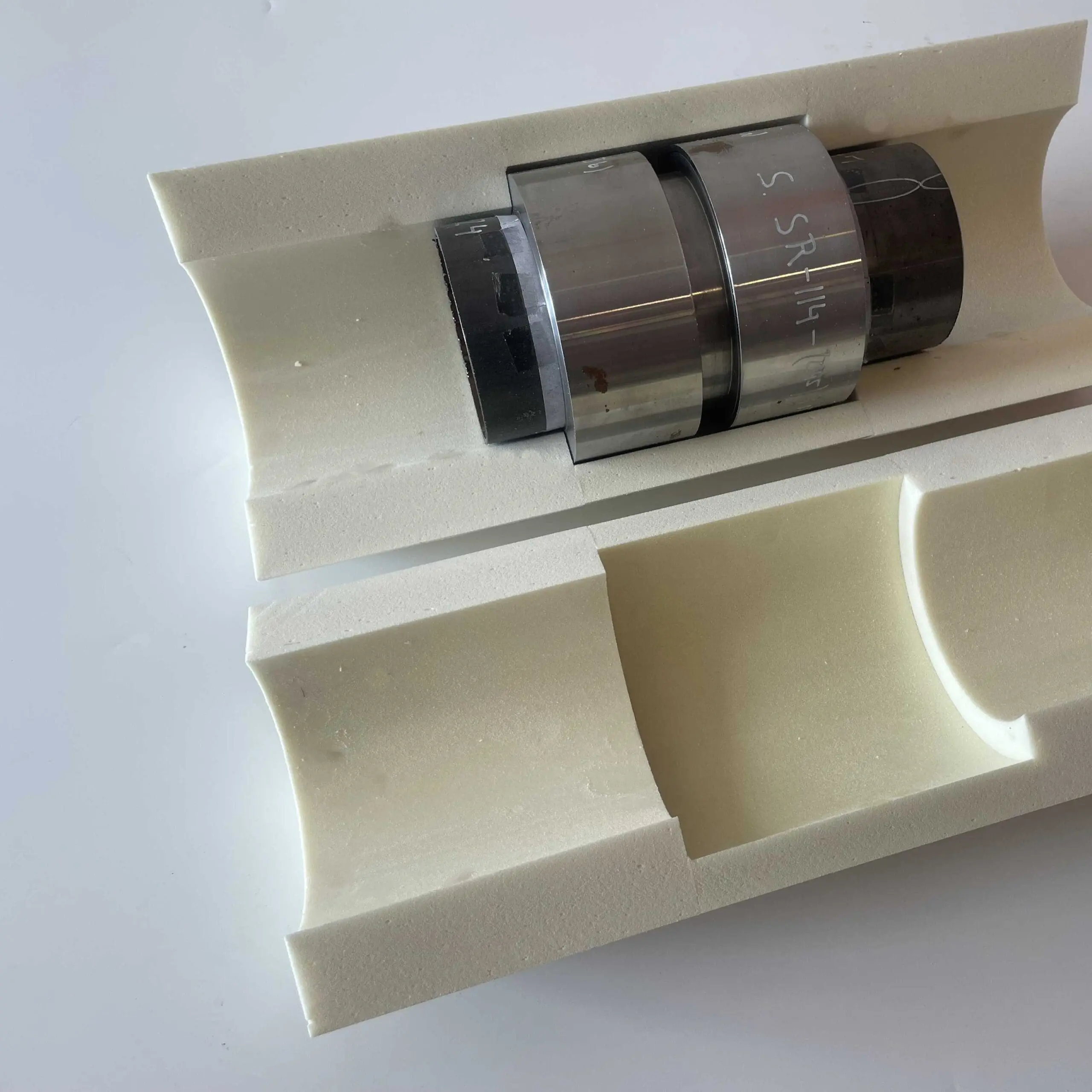

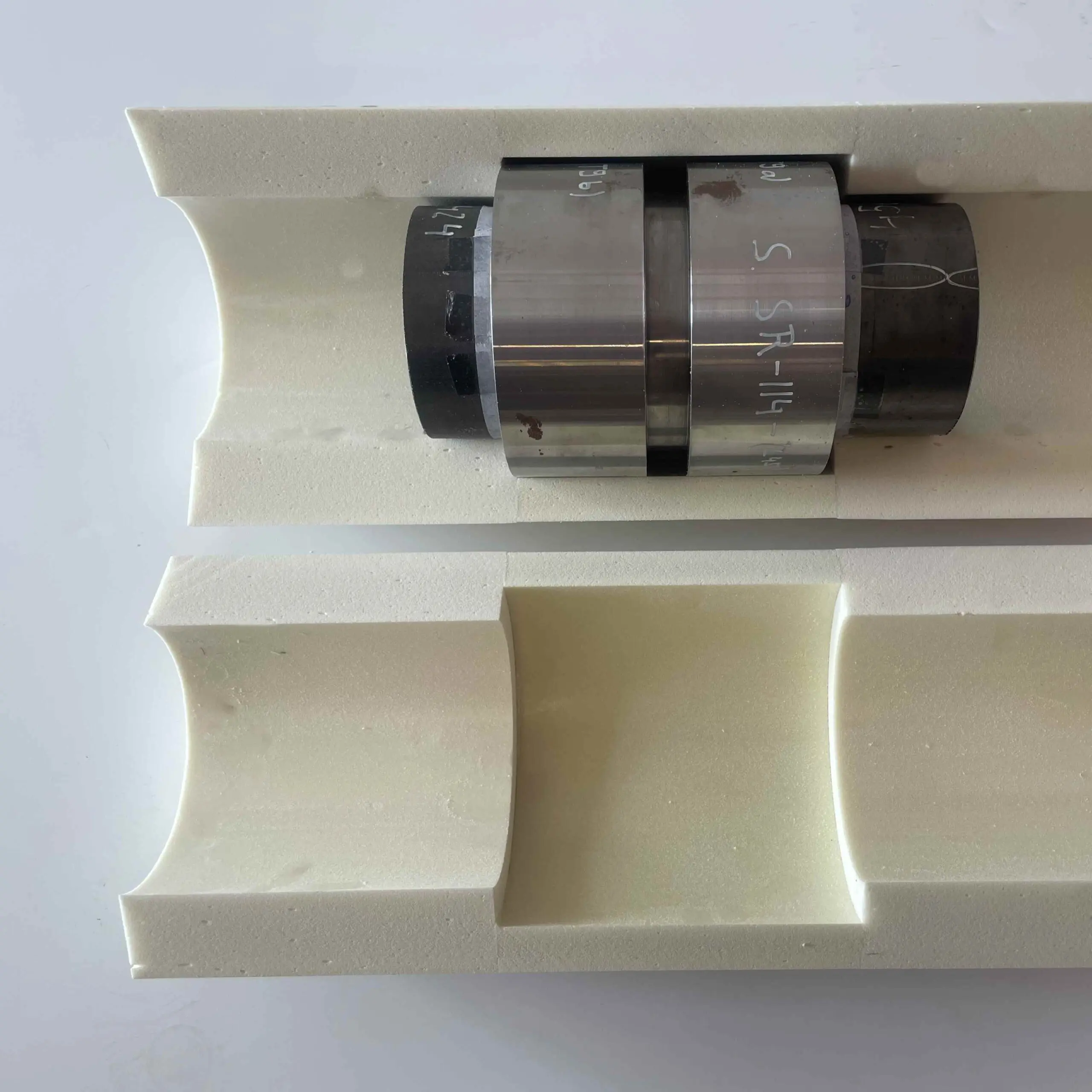

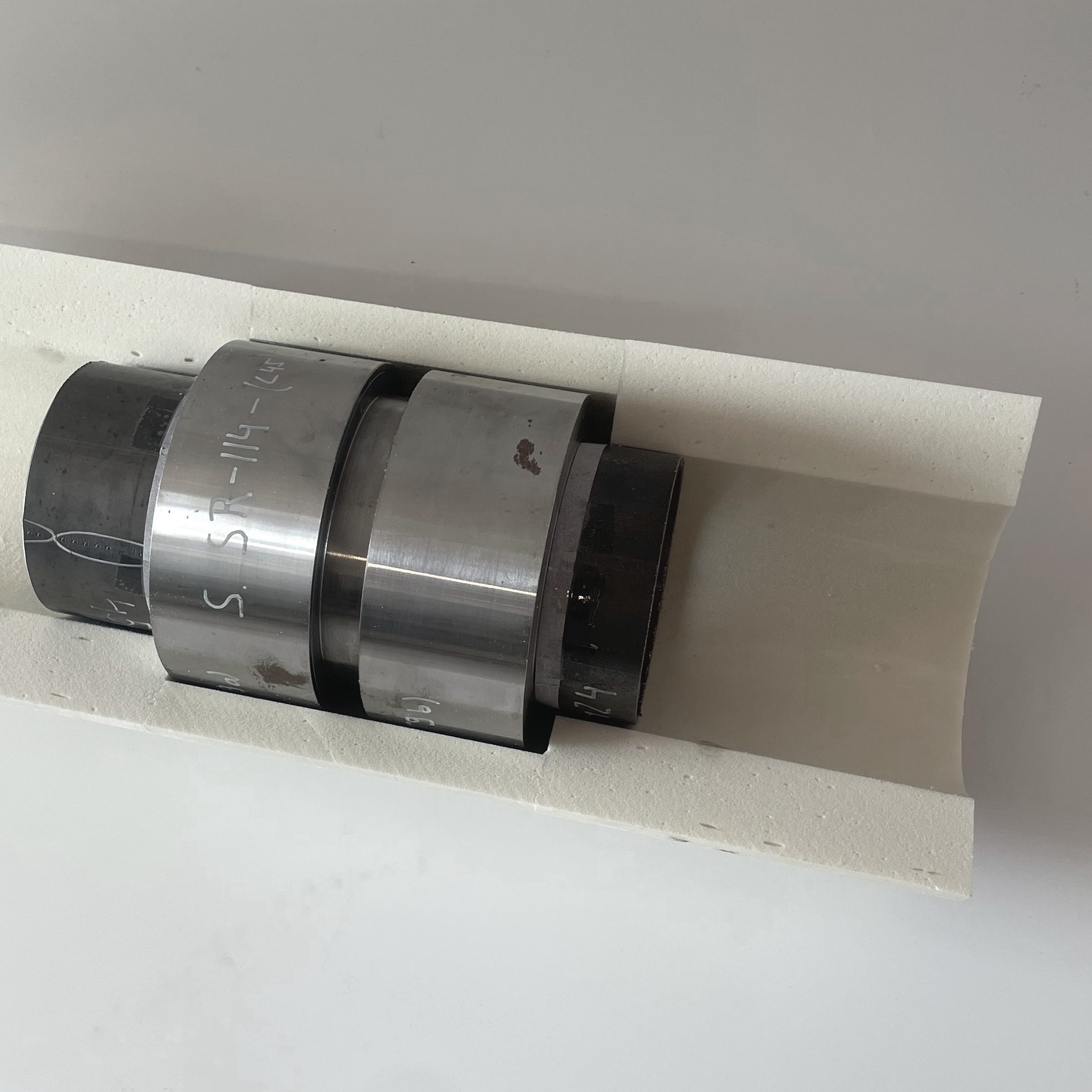

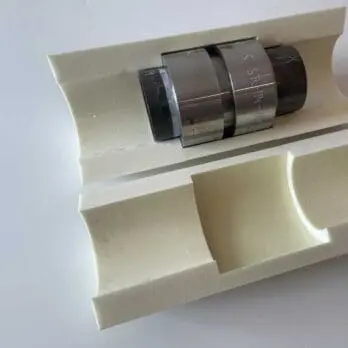

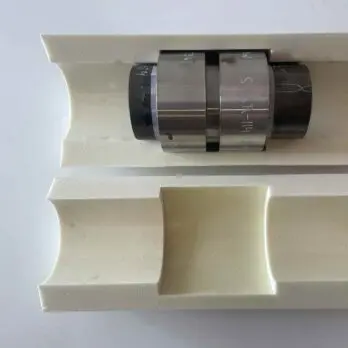

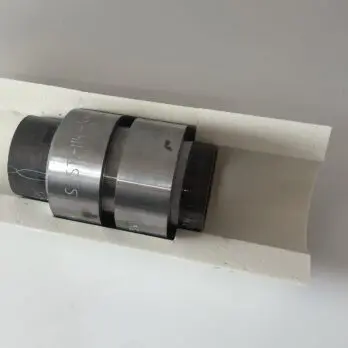

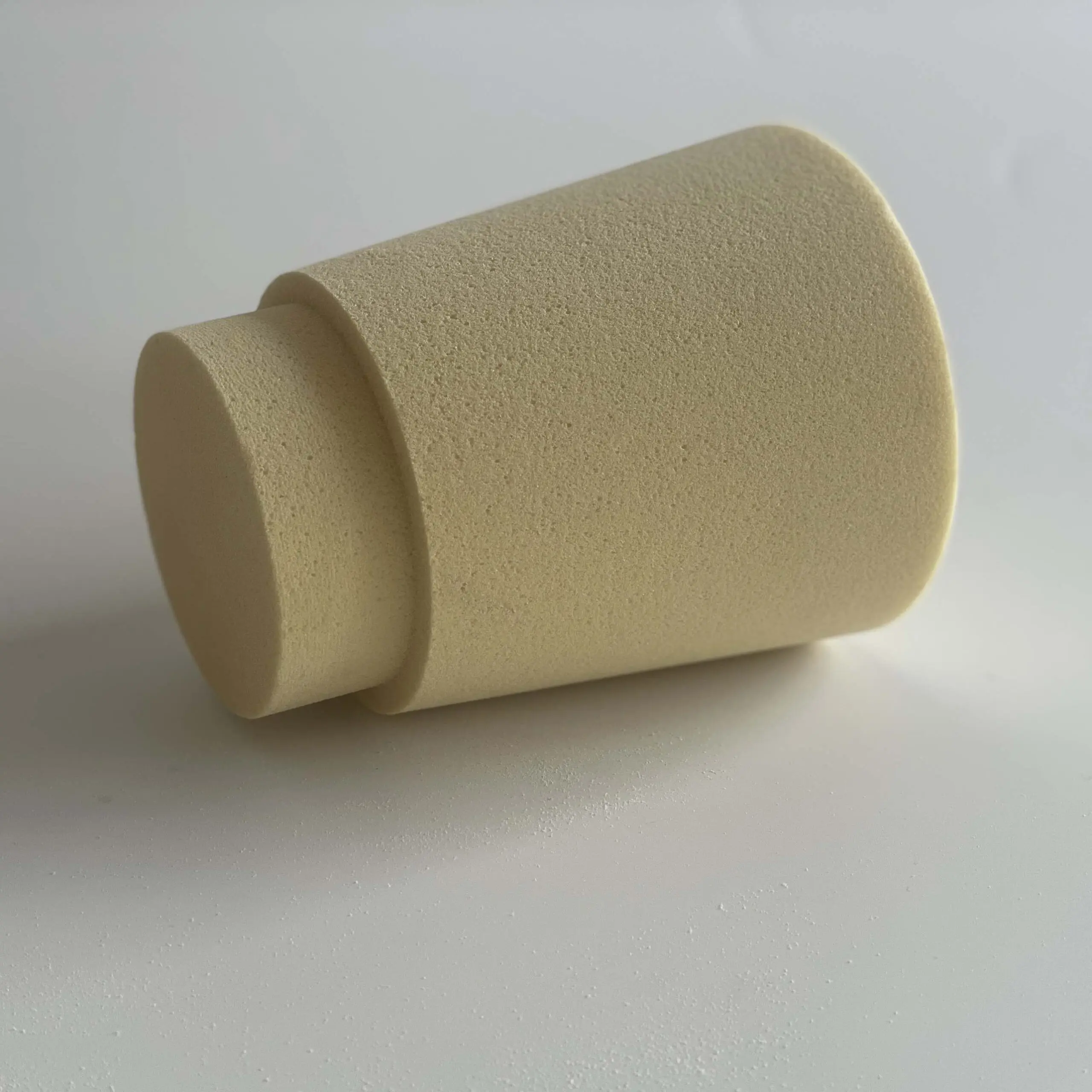

Press couplings in polyurethane

Effective insulation and sealing

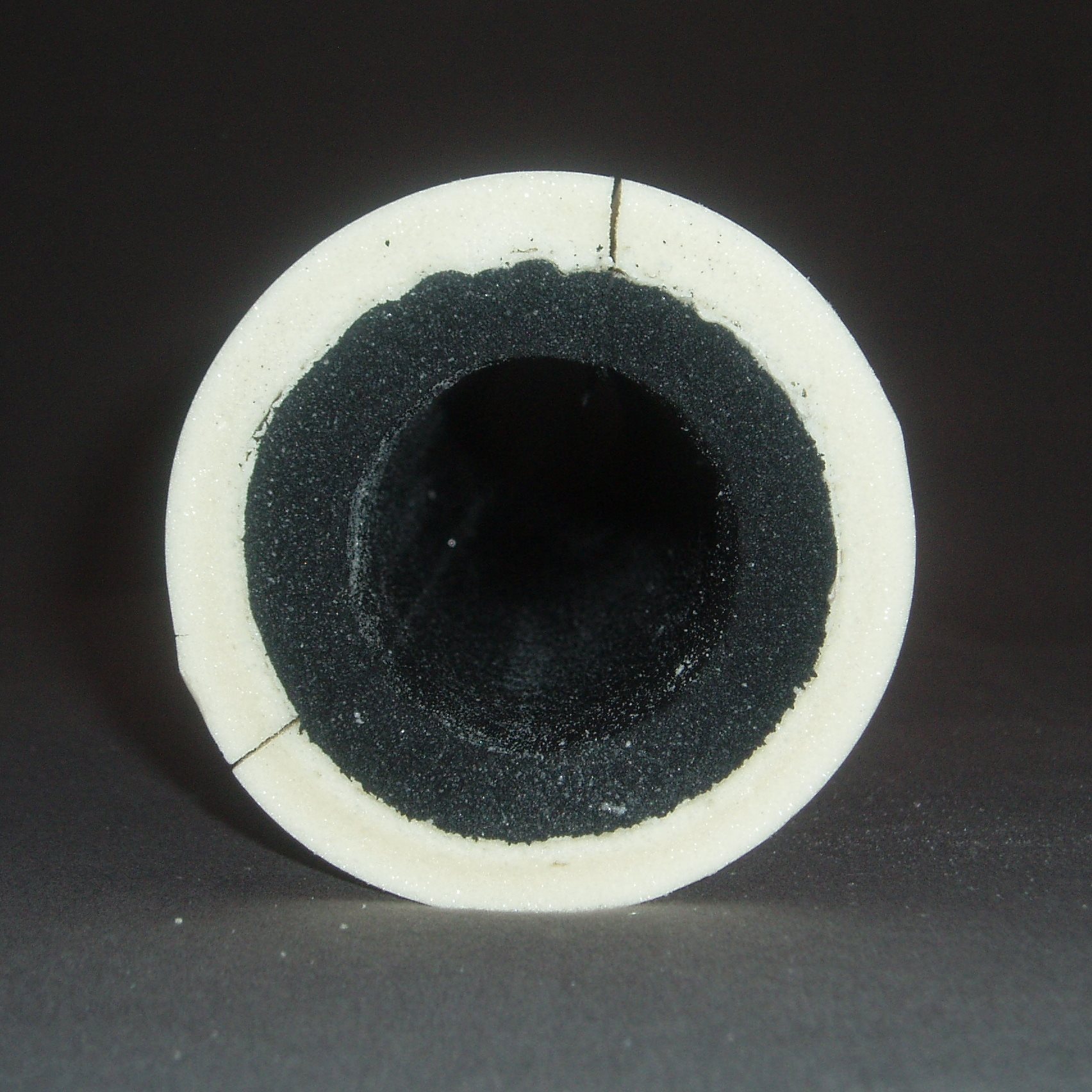

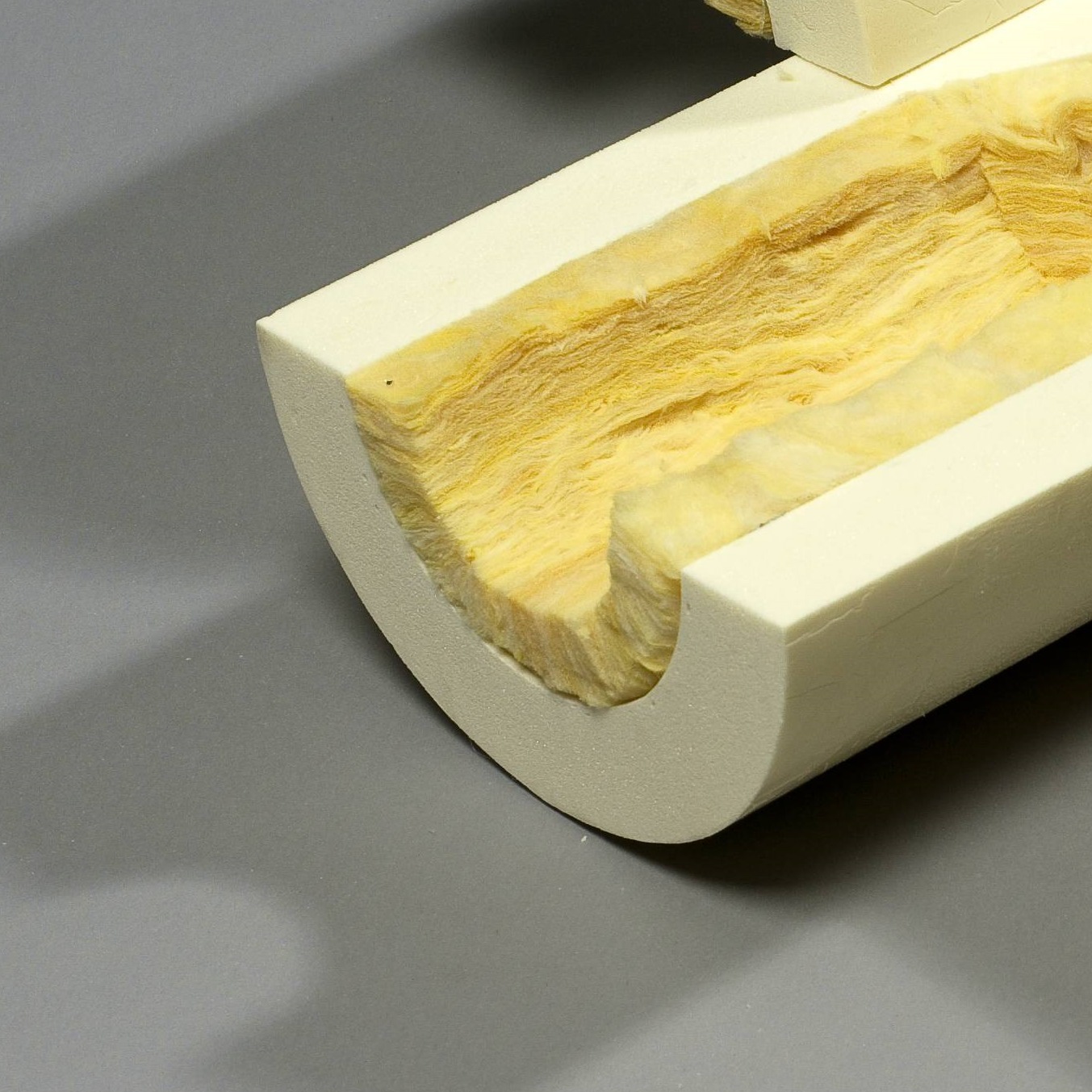

Polyurethane compression fittings are an ideal solution for effective pipe insulation and sealing in a range of industrial and commercial applications. With their superior insulation properties and durability, polyurethane press couplings offer a reliable method of ensuring both thermal protection and structural stability.

At Dan-iso, we produce molded polyurethane pipe bowls that fit perfectly with HAELOK.

Advantages of polyurethane press couplings:

1. Effective insulation: Polyurethane has a low thermal conductivity, which makes it particularly effective in minimizing heat loss and improving energy efficiency in pipe installations.

2. Long durability: The material is resistant to mechanical stress, chemicals and extreme temperatures, ensuring long-lasting performance even under demanding conditions.

3. Flexibility: Polyurethane compression fittings can be adapted to different pipe sizes and configurations, making them suitable for complex installation projects.

4. Easy installation: Designed to ensure tight connections, polyurethane press couplings are both easy to install and maintain, saving time and cost.

5. Sustainability: By reducing heat loss, our press couplings contribute to a more energy-efficient operation and a more sustainable solution.

Application

Polyurethane insulation for press couplings

Polyurethane insulation for press couplings is a reliable and efficient solution for a wide range of industrial and technical systems where both sealing and insulation are essential. They are ideal for installations that require high precision, long-term durability and optimal performance. Here are some of the main applications of polyurethane press couplings:

HVAC systems

In HVAC (Heating, Ventilation, and Air Conditioning) systems, polyurethane insulation ensures a tight and efficient connection to press fittings between pipes and components. They prevent energy loss, improve system performance and reduce the risk of condensation. Their insulating properties make them perfect for both heating and cooling systems where temperature control is important.

Cooling system

Polyurethane insulation for compression fittings is often used in refrigeration plants where precise sealing and insulation are necessary to maintain efficient operation and prevent energy loss. Their durability and resistance to extremely cold temperatures make them ideal for use in both industrial and commercial refrigeration systems.

Heating installations

In heating installations, polyurethane insulation for press couplings plays a central role in ensuring correct sealing and insulation of pipe systems. They prevent heat loss and ensure that the heat is conducted efficiently through the system. Their flexible design makes installation quick and efficient, which is an advantage in both new and upgrade projects.

Industrial pipe installations

Insulation for press fittings in polyurethane is also suitable for general industrial pipe installations where high mechanical strength and resistance to temperature fluctuations are required. They provide a reliable and long-lasting solution for pipe connections that require both sealing and insulation.

The oil and gas industry

In the oil and gas industry, where piping systems operate under extreme conditions, compression fitting insulation is used to ensure sealing and protect against mechanical damage. The resistance to both high and low temperatures makes them ideal for installations that require reliable sealing and thermal protection.

Polyurethane insulation for press couplings is therefore a versatile solution that can be used in many different systems where both effective sealing and insulation are necessary. Their reliable performance makes them a popular solution in both new installations and upgrade projects where high quality and durability are essential.

Also explore Dan-iso customized special products for additional possibility of effective insulation.

Technical data sheet

Contact us for product sheet.

Technical specifications

| Material properties | Value | Standard |

|---|---|---|

| Density | 68 kg/m3 (±8 kg/m3) | ISO 845 (/DIN 53420-78) |

| Closed cells | ≥ 88 % | ISO 4590 |

| Cell size | < 0.5 mm | EN253 5.3.2.1 |

| Water absorption during boiling | Mean value 4.4 % Vol | EN253 5.3.5 |

| Compressive strength, radial | ≥ 0.40 Mpa | ISO 844 |

| E-module, radial | ≥ 9.5 MPa | ISO 844 |

| Dimensional stability | ||

| -30 C° | 48h: 0.0 % vol | |

| +100 C° | 48h: -1.0 % vol | ISO 2796 (/DIN 53431-77) |

| +150 C° | 48h: -1.4 % vol | |

| Thermal Insulation Value (thermal conductivity) | ||

| λ10 | 0.0238 W/m*K | |

| λ20 | 0.0247 W/m*K | ISO 8301 / ASTM C518 |

| λ50 | 0.0284 W/m*K | |

| Fire class | B3 | DIN 4102 Part 1 |