Optimal thermal protection and durability

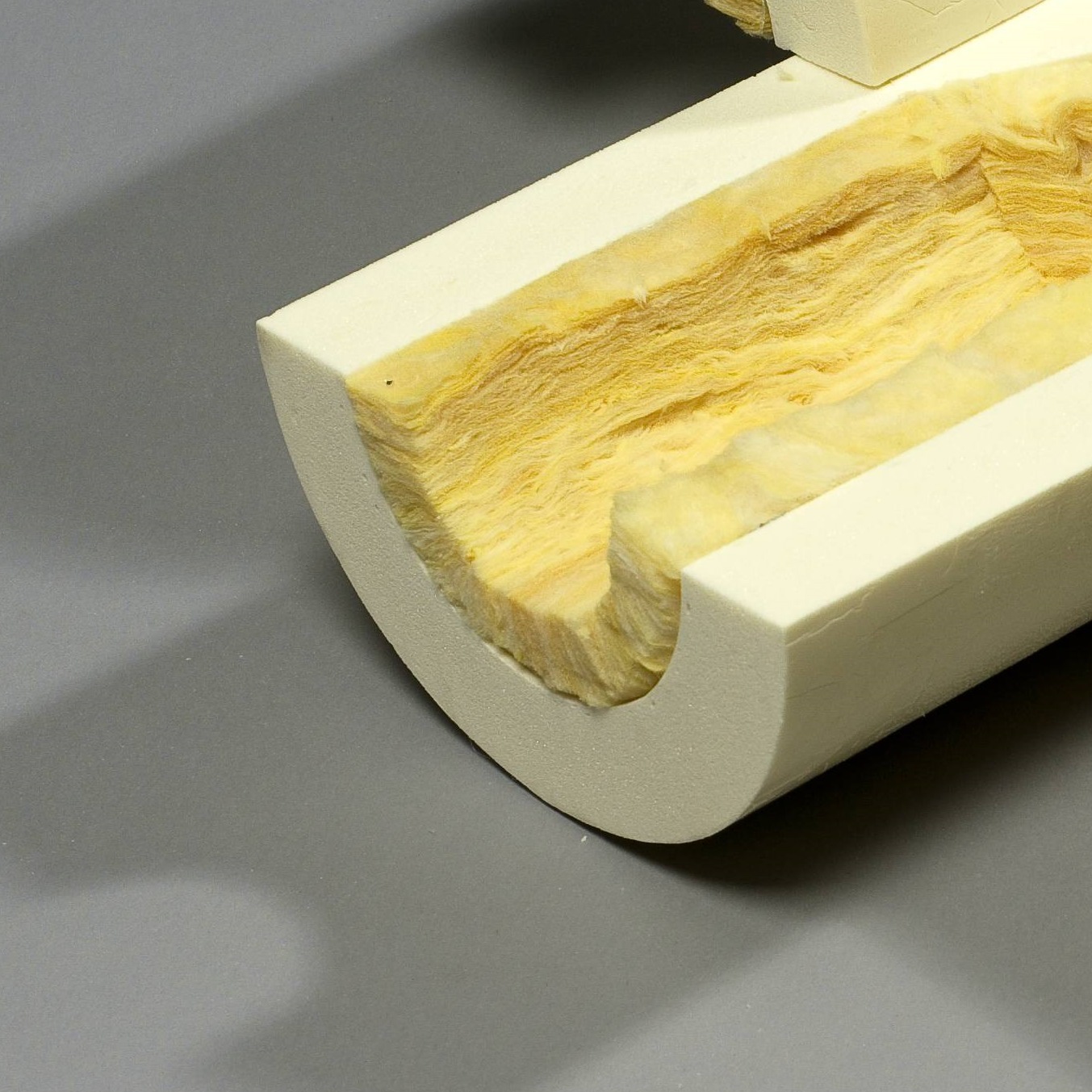

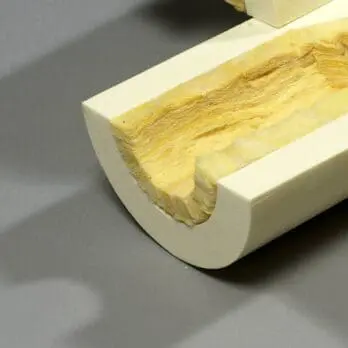

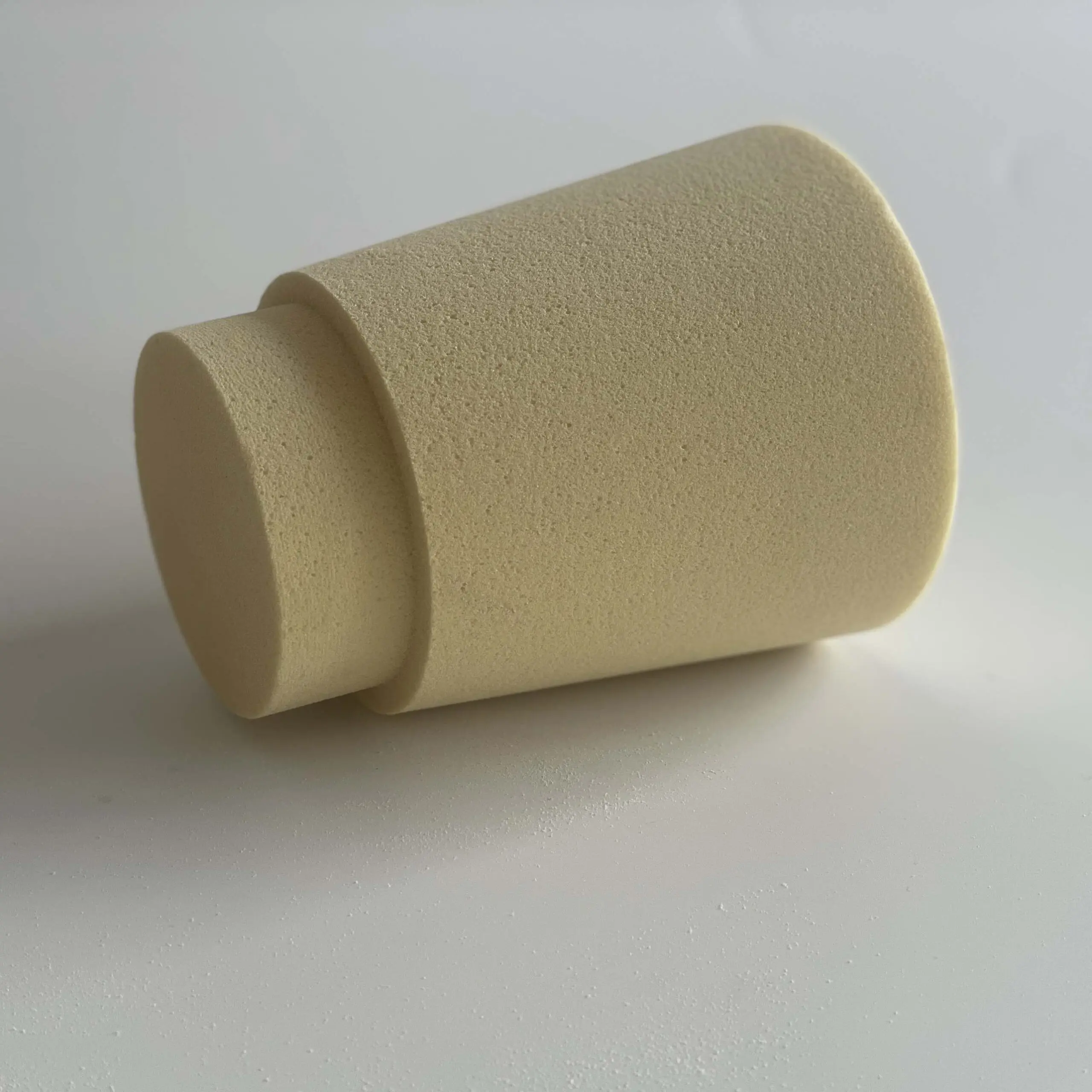

Polyurethane bowls combined with mineral wool

Discover the effective solution for thermal protection with our polyurethane bowls combined with mineral wool.

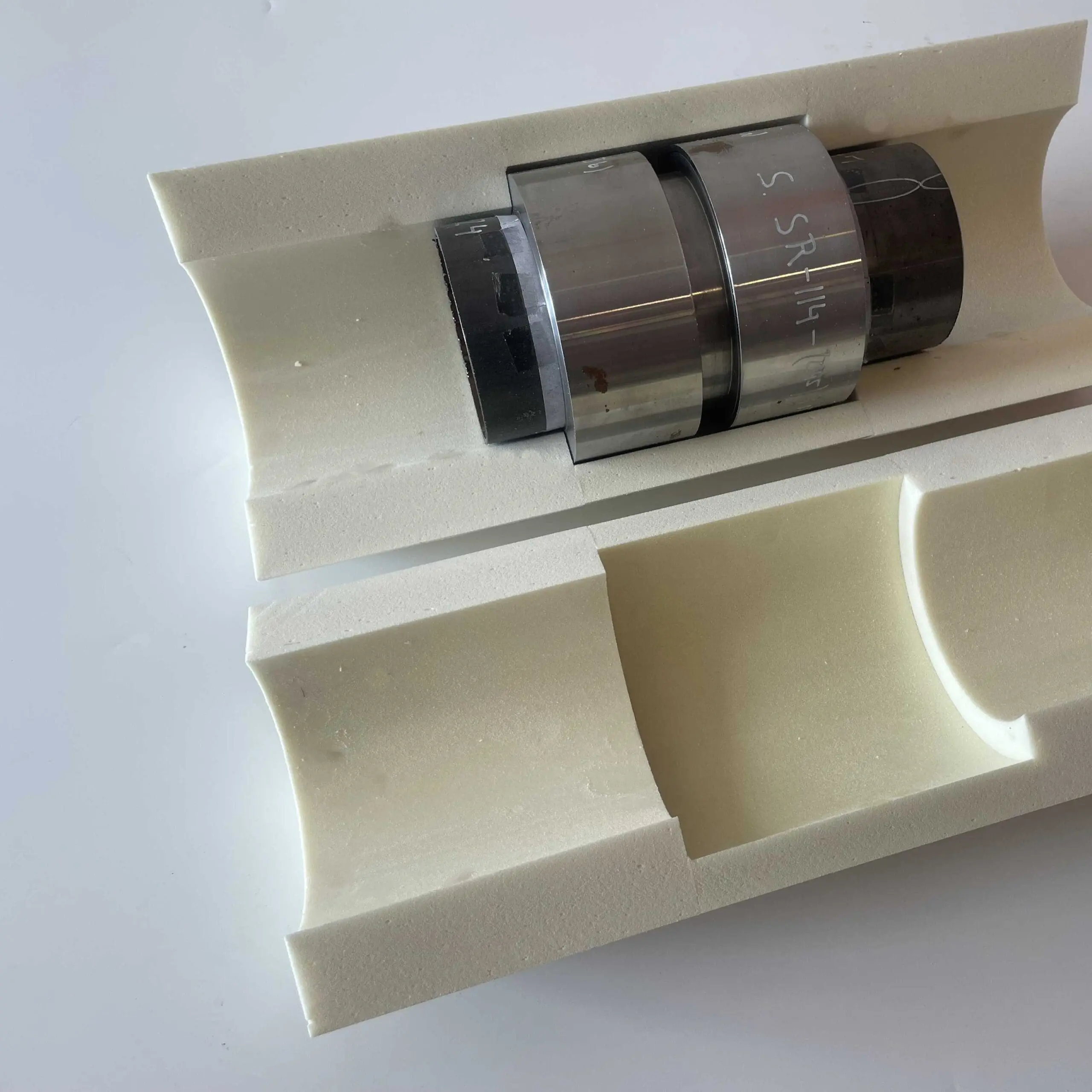

These insulation products are created to deliver optimum performance and durability, making them perfect for both industrial and commercial applications.

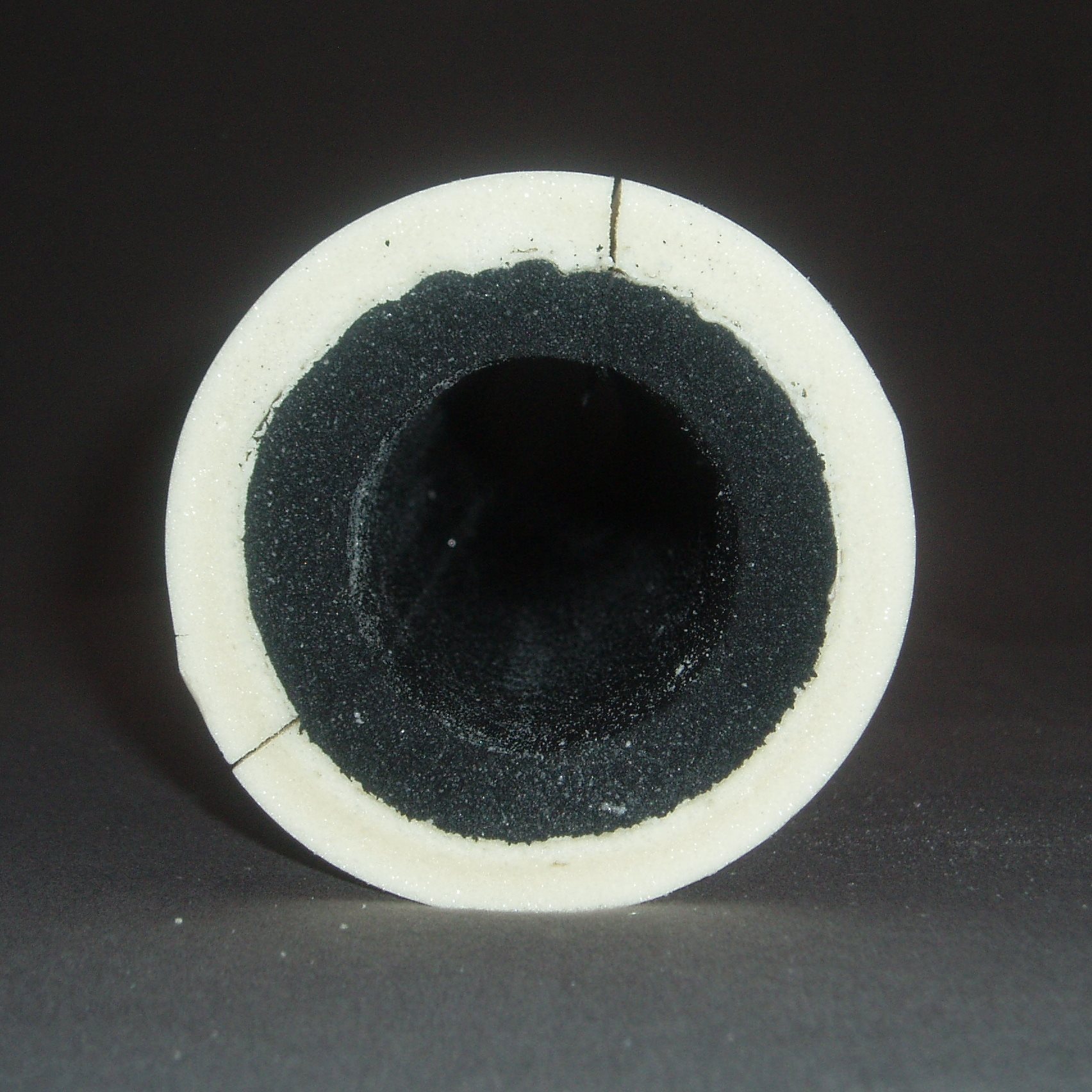

PUR polyurethane pipe insulation bowls with mineral wool ensure highly effective insulation that significantly reduces heat loss and increases energy efficiency in pipe installations. The tube cups are resistant to high temperatures and mechanical stress, which ensures the long life and reliable performance.

With its excellent thermal properties and lightweight construction, the tube trays are easy to install and maintain – and cost-effective.

In order to protect the polyurethane and increase the insulation value for applications where the media temperature exceeds 140 degrees C, mineral wool is used in our pipe bowls. The mineral wool can be adjusted in thickness according to specifications, giving you a tailor-made solution for your insulation needs.

Application

Extra protection against extreme conditions

Polyurethane (PUR) pipe insulation with internal wool protection is particularly suitable for use in systems where both high insulation performance and extra protection against extreme conditions are necessary. This combination of materials makes the insulation ideal for a number of industrial and technical applications, where the requirements for both thermal insulation, mechanical protection and resistance to temperature fluctuations are high.

Industrial pipe installations

PUR pipe insulation with internal wool protection is often used in large industrial pipe installations where the pipes are exposed to extreme temperatures and mechanical stress. The wool acts as an extra protective layer against physical damage and moisture, while the PUR insulation prevents heat loss and ensures energy-efficient operation.

HVAC systems

In HVAC (Heating, Ventilation, and Air Conditioning) systems, this type of insulation is used to maintain a constant temperature in pipes and ducts. The inner wool protection helps prevent condensation and protects the pipes from mechanical damage, while PUR ensures effective thermal insulation and prevents energy loss.

Cooling systems

For cooling systems, where pipes and components are often exposed to both hot and cold temperatures, PUR pipe insulation with wool protection offers the necessary insulation to avoid frost damage and reduce energy consumption. The wool's properties improve protection against extreme temperatures and prevent condensation from penetrating the insulation.

The oil and gas industry

In the oil and gas industry, where piping systems operate under extremely demanding conditions, PUR pipe insulation with internal wool protection is used to ensure that the pipes remain protected against both mechanical damage and temperature fluctuations. This ensures efficient operation and extends the life of the pipe installation.

Construction and renovation

In construction and renovation, this type of pipe insulation is ideal for installations that require high temperature control, such as heating and water pipes. PUR and wool protection provide both good insulation and protection against damage during construction or renovation, which ensures long-term durability.

Polyurethane pipe insulation with internal wool protection is therefore a versatile solution that is effective in ensuring thermal insulation, protecting against condensation and mechanical damage, as well as increasing energy efficiency in many different industrial and technical installations.

Also explore our Dan-isoMOLD pipe insulation with internal foam protection – Dan-isoMOLD with foam.

Technical data sheet

Contact us for product sheet.

Technical specifications

| Material properties | Value | Standard |

|---|---|---|

| Density | 68 kg/m3 (±8 kg/m3) | ISO 845 (/DIN 53420-78) |

| Closed cells | ≥ 88 % | ISO 4590 |

| Cell size | < 0.5 mm | EN253 5.3.2.1 |

| Water absorption during boiling | Mean value 4.4 % Vol | EN253 5.3.5 |

| Compressive strength, radial | ≥ 0.40 Mpa | ISO 844 |

| E-module, radial | ≥ 9.5 MPa | ISO 844 |

| Dimensional stability | ||

| -30 C° | 48h: 0.0 % vol | |

| +100 C° | 48h: -1.0 % vol | ISO 2796 (/DIN 53431-77) |

| +150 C° | 48h: -1.4 % vol | |

| Thermal Insulation Value (thermal conductivity) | ||

| λ10 | 0.0238 W/m*K | |

| λ20 | 0.0247 W/m*K | ISO 8301 / ASTM C518 |

| λ50 | 0.0284 W/m*K | |

| Fire class | B3 (Normal combustible) | DIN 4102 Part 1 |